polyurethane wire screen panel,PU sieve panel,polyurethane wire mesh panel

Exploring the Benefits and Applications of polyurethane wire screen panels polyurethane wire screen panels, also known as pu sieve panels or polyurethane…

Exploring the Benefits and Applications of polyurethane wire screen Panels

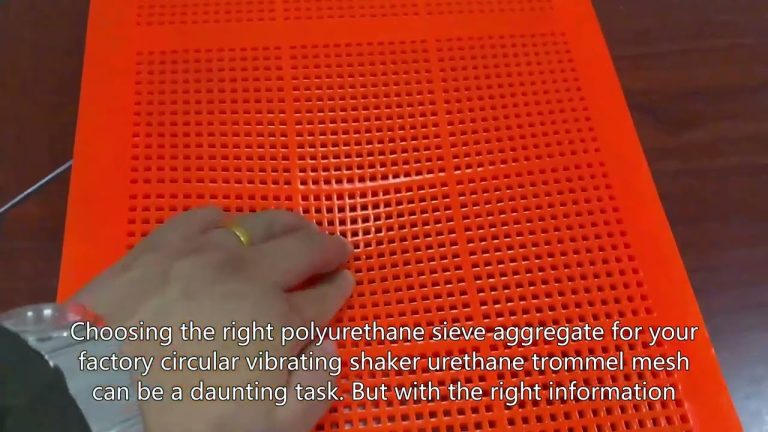

Polyurethane wire screen panels, also known as pu sieve panels or polyurethane wire mesh panels, are innovative products that have revolutionized the screening industry. These panels are renowned for their durability, efficiency, and versatility, making them a preferred choice for various industrial applications. This article aims to explore the benefits and applications of these panels, shedding light on why they are increasingly becoming a staple in numerous industries. One of the most significant advantages of polyurethane wire screen panels is their exceptional durability. These panels are made from high-quality polyurethane, a material known for its resistance to wear and tear. Unlike traditional metal screens, polyurethane wire screen panels can withstand harsh conditions, including abrasive materials and heavy loads, without compromising their performance. This durability translates into cost savings, as the need for frequent replacements is significantly reduced. In addition to their robustness, polyurethane wire screen panels are also recognized for their efficiency. They are designed with precision to ensure optimal screening performance. The panels feature a unique wire mesh design that allows for effective separation and classification of materials. This design not only enhances the screening process but also minimizes the chances of blockages, thereby improving productivity. Another notable benefit of polyurethane wire screen panels is their versatility. These panels can be customized to meet specific requirements, making them suitable for a wide range of applications. Whether it’s mining, quarrying, or recycling, polyurethane wire screen panels can be tailored to fit different machines and handle various materials. This adaptability makes them a practical solution for diverse industrial needs. The benefits of polyurethane wire screen panels extend beyond their physical attributes. These panels are also environmentally friendly. Polyurethane is a recyclable material, meaning that once the panels reach the end of their lifespan, they can be recycled into new products. This feature aligns with the growing emphasis on sustainability in the industrial sector, making polyurethane wire screen panels a green choice. Now, let’s delve into the applications of polyurethane wire screen panels. One of the primary uses of these panels is in the mining industry. Given their durability and efficiency, they are ideal for screening and separating different types of minerals. The panels’ resistance to wear and tear makes them suitable for handling abrasive materials commonly found in mining operations. In the quarrying industry, polyurethane wire screen panels are used for grading and sorting aggregates. Their precise mesh design ensures accurate separation, contributing to the production of high-quality aggregates. Similarly, in the recycling industry, these panels play a crucial role in separating and classifying recyclable materials. Their ability to withstand heavy loads makes them perfect for handling the rigorous demands of recycling processes. In conclusion, polyurethane wire screen panels, or PU sieve panels, offer numerous benefits that make them an excellent choice for various industrial applications. Their durability, efficiency, versatility, and environmental friendliness are attributes that set them apart from traditional screening solutions. Whether it’s mining, quarrying, or recycling, these panels can deliver superior performance, contributing to increased productivity and cost savings. As industries continue to evolve and demand more from their equipment, polyurethane wire screen panels are poised to meet these challenges head-on.

In conclusion, polyurethane wire screen panels, or PU sieve panels, offer numerous benefits that make them an excellent choice for various industrial applications. Their durability, efficiency, versatility, and environmental friendliness are attributes that set them apart from traditional screening solutions. Whether it’s mining, quarrying, or recycling, these panels can deliver superior performance, contributing to increased productivity and cost savings. As industries continue to evolve and demand more from their equipment, polyurethane wire screen panels are poised to meet these challenges head-on.