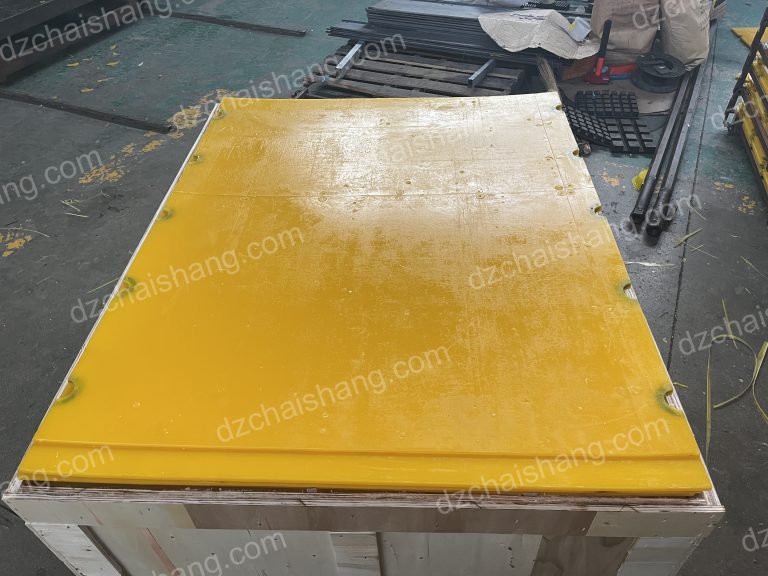

Polyurethane screen panels,Polyurethane panels in vibrating screen

Durability and Performance: Comparing polyurethane screen panels to Traditional Materials in Vibrating screens Polyurethane screen panels have emerged as a superior alternative…

Durability and Performance: Comparing polyurethane screen panels to Traditional Materials in Vibrating screens

Polyurethane screen panels have emerged as a superior alternative to traditional screening materials such as wire mesh and steel in vibrating screens. Known for their resilience and high performance, these panels are increasingly preferred for a variety of industrial applications, ranging from mining to aggregate processing. Understanding the advantages of polyurethane in terms of durability and performance can illuminate why it is becoming the material of choice in such demanding environments.

Traditionally, vibrating screens have utilized metal wire mesh or steel plates, which, while effective initially, often face degradation in the form of corrosion or wire breakage. This degradation not only necessitates frequent replacements but can also lead to downtime and increased operational costs. In contrast, polyurethane offers a robust solution with its exceptional abrasion resistance. This intrinsic quality of polyurethane significantly extends the lifespan of screen panels by resisting wear from both the material being screened and environmental factors such as moisture and temperature variations. Moreover, polyurethane’s flexibility adds to its durability. Unlike rigid steel plates that can suffer from fatigue and fracture under continuous vibration, Polyurethane Panels are flexible, which allows them to absorb impact more effectively. This flexibility ensures that the panels can withstand considerable force without losing integrity, thereby maintaining their form and effectiveness over time. Furthermore, this resilience against impact reduces the likelihood of blinding and clogging, especially when screening sticky or wet materials, thus maintaining screening efficiency and reducing maintenance requirements.

Another notable advantage of polyurethane screen panels is their noise reduction capability. Vibrating screens can generate significant noise, which poses challenges in terms of workplace safety and environmental compliance. Polyurethane inherently dampens vibration and reduces the sound emanating from the operation, contributing to a safer and more compliant work environment. Additionally, the reduced noise level enhances the comfort and productivity of personnel working in close proximity to the equipment. Performance-wise, polyurethane screen panels can be engineered with varying levels of hardness and other physical properties to suit specific applications. This customization potential allows for optimal performance tailored to specific materials and conditions encountered in different industries. Whether the task involves fine particle separation in sand and gravel or handling coarse material in mining operations, polyurethane’s adaptability ensures that the screens perform efficiently under all circumstances. Furthermore, the installation and replacement of polyurethane panels are notably more straightforward compared to traditional materials. Their lightweight nature, combined with modular designs, allows for easy handling and quick changes. This not only cuts down on installation time but also minimizes the screen’s downtime, thereby enhancing productivity. In conclusion, the transition from traditional materials like wire mesh and steel to polyurethane screen panels in vibrating screens is underpinned by the material’s superior durability and performance. With advantages ranging from improved wear resistance and flexibility to noise reduction and customization, polyurethane panels stand out as a practical choice for industries looking to optimize their screening processes. As technology continues to advance, the role of polyurethane in enhancing industrial screening solutions is set to grow, promising even greater efficiency and cost-effectiveness in the future.