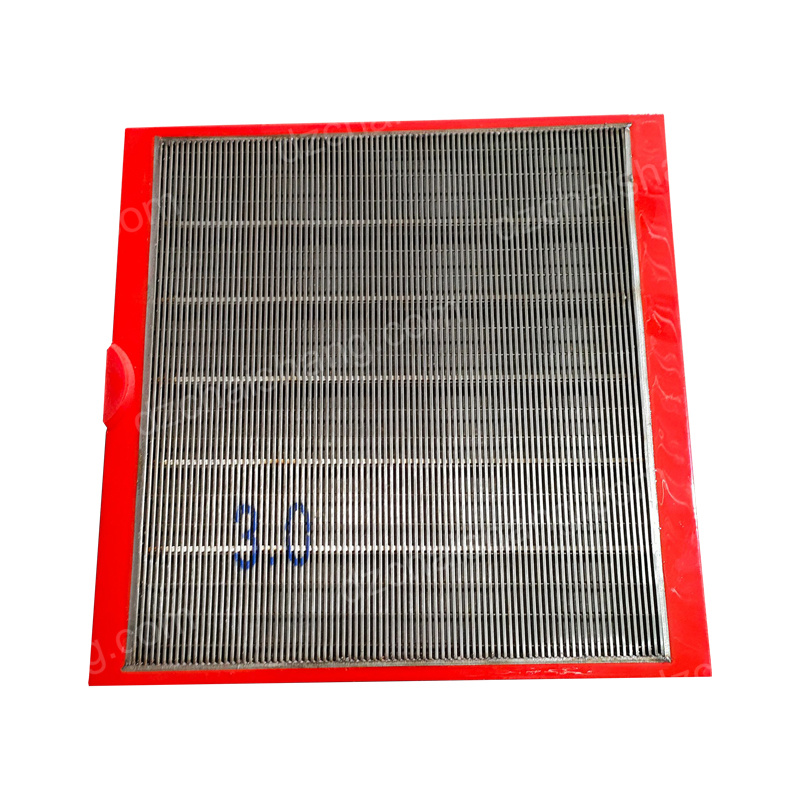

polyurethane mining screens,polyurethane modular screen mesh

Advantages of polyurethane mining screens in Mineral Processing Polyurethane mining screens have become increasingly popular in the mineral processing industry due to…

Advantages of polyurethane mining screens in Mineral Processing

Polyurethane mining screens have become increasingly popular in the mineral processing industry due to their numerous advantages over traditional metal screens. These screens are made from a durable and flexible material that offers a range of benefits, making them a preferred choice for many mining operations. One of the key advantages of polyurethane mining screens is their longevity. Unlike metal screens, which can corrode and wear out over time, polyurethane screens are resistant to abrasion and corrosion. This means that they have a longer lifespan and require less frequent replacement, saving mining companies time and money in the long run. In addition to their durability, polyurethane mining screens are also highly flexible. This flexibility allows the screens to be easily molded into different shapes and sizes, making them ideal for a variety of screening applications. Whether it’s scalping, sizing, dewatering, or washing, polyurethane screens can be customized to meet the specific needs of each mining operation. Another advantage of polyurethane mining screens is their efficiency. These screens are designed to maximize screening efficiency by allowing for more material to pass through the screen openings. This results in higher throughput and increased productivity, ultimately leading to improved overall performance in mineral processing operations.Polyurethane screens are also known for their superior screening performance. The material’s unique properties, such as its high tensile strength and elasticity, allow for efficient screening of even the most challenging materials. This means that polyurethane screens can effectively separate particles of varying sizes, ensuring a high-quality end product. Furthermore, polyurethane mining screens are easy to install and maintain. Their lightweight design makes them easy to handle and transport, while their modular construction allows for quick and simple installation. Additionally, polyurethane screens are easy to clean and require minimal maintenance, further reducing downtime and increasing operational efficiency. Polyurethane screens are also environmentally friendly. Unlike metal screens, which can release harmful chemicals and pollutants into the environment, polyurethane screens are non-toxic and safe for use in mineral processing operations. This makes them a sustainable and eco-friendly choice for mining companies looking to reduce their environmental impact. Overall, polyurethane mining screens offer a range of advantages that make them a superior choice for mineral processing operations. From their durability and flexibility to their efficiency and performance, polyurethane screens provide numerous benefits that can help mining companies improve their operations and achieve greater success. In conclusion, polyurethane mining screens are a valuable investment for any mining operation looking to enhance their mineral processing capabilities. With their durability, flexibility, efficiency, and environmental friendliness, polyurethane screens offer a range of advantages that can help mining companies achieve optimal performance and productivity.

The Role of Polyurethane modular screen mesh in Efficient Screening

Polyurethane modular screen mesh has become an essential component in the mining industry for efficient screening. This innovative material offers a range of benefits that make it superior to traditional metal screens. From increased durability to improved screening efficiency, polyurethane modular screen mesh is revolutionizing the way mining operations are conducted. One of the key advantages of polyurethane modular screen mesh is its durability. Unlike metal screens, which are prone to corrosion and wear, polyurethane screens are resistant to abrasion and can withstand harsh operating conditions. This longevity translates to cost savings for mining companies, as they do not have to frequently replace worn-out screens. In addition to its durability, polyurethane modular screen mesh also offers superior screening efficiency. The flexibility of the material allows for increased screening area, resulting in higher throughput and improved product quality. The modular design of the screens also makes them easy to install and replace, reducing downtime and increasing overall productivity. Another benefit of polyurethane modular screen mesh is its ability to reduce noise levels in mining operations. The material absorbs vibrations and dampens sound, creating a quieter working environment for miners. This not only improves the overall comfort of workers but also enhances safety by reducing noise-related distractions. Polyurethane modular screen mesh is also environmentally friendly, as it is recyclable and non-toxic. This makes it a sustainable choice for mining companies looking to reduce their environmental impact. Additionally, the lightweight nature of polyurethane screens reduces energy consumption during transportation and installation, further contributing to their eco-friendliness.

Overall, polyurethane modular screen mesh plays a crucial role in efficient screening in the mining industry. Its durability, screening efficiency, noise reduction capabilities, and environmental friendliness make it a superior choice to traditional metal screens. As mining operations continue to evolve and demand higher levels of productivity, polyurethane modular screen mesh will undoubtedly become an even more essential component in the screening process. In conclusion, polyurethane modular screen mesh is a game-changer in the mining industry. Its numerous benefits make it a superior choice for efficient screening, offering durability, screening efficiency, noise reduction, and environmental friendliness. As mining companies strive to increase productivity and reduce costs, polyurethane modular screen mesh will continue to play a vital role in achieving these goals.