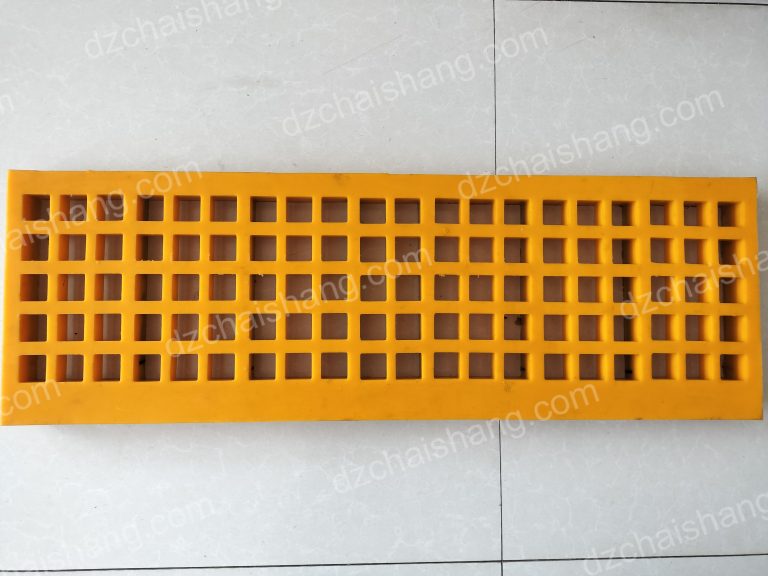

High quality PU vibrating screen panels for vibrating sieve machine

Benefits And Applications Of High-Quality PU vibrating screen panels In Various Industries High-quality PU (polyurethane) vibrating screen panels are increasingly becoming the…

Benefits And Applications Of High-Quality PU vibrating screen panels In Various Industries

High-quality PU (polyurethane) vibrating screen panels are increasingly becoming the material of choice for vibrating sieve machines across various industries. Their superior durability, efficiency, and versatility make them indispensable in settings that require rigorous material separation and screening processes. This article explores the benefits and applications of these panels, highlighting why they are preferred over traditional materials like metal or rubber. One of the primary advantages of PU vibrating screen panels is their exceptional durability. Polyurethane is known for its resistance to wear, abrasion, and tearing, making it ideal for use in high-impact environments where screens may be subject to heavy loads and continuous use. This resilience not only extends the lifespan of the screen panels but also reduces the frequency of replacements, thereby enhancing operational efficiency and reducing downtime in industrial processes.Comparison Of High-Quality PU Vibrating Screen Panels With Other Materials In Vibrating Sieve Machines

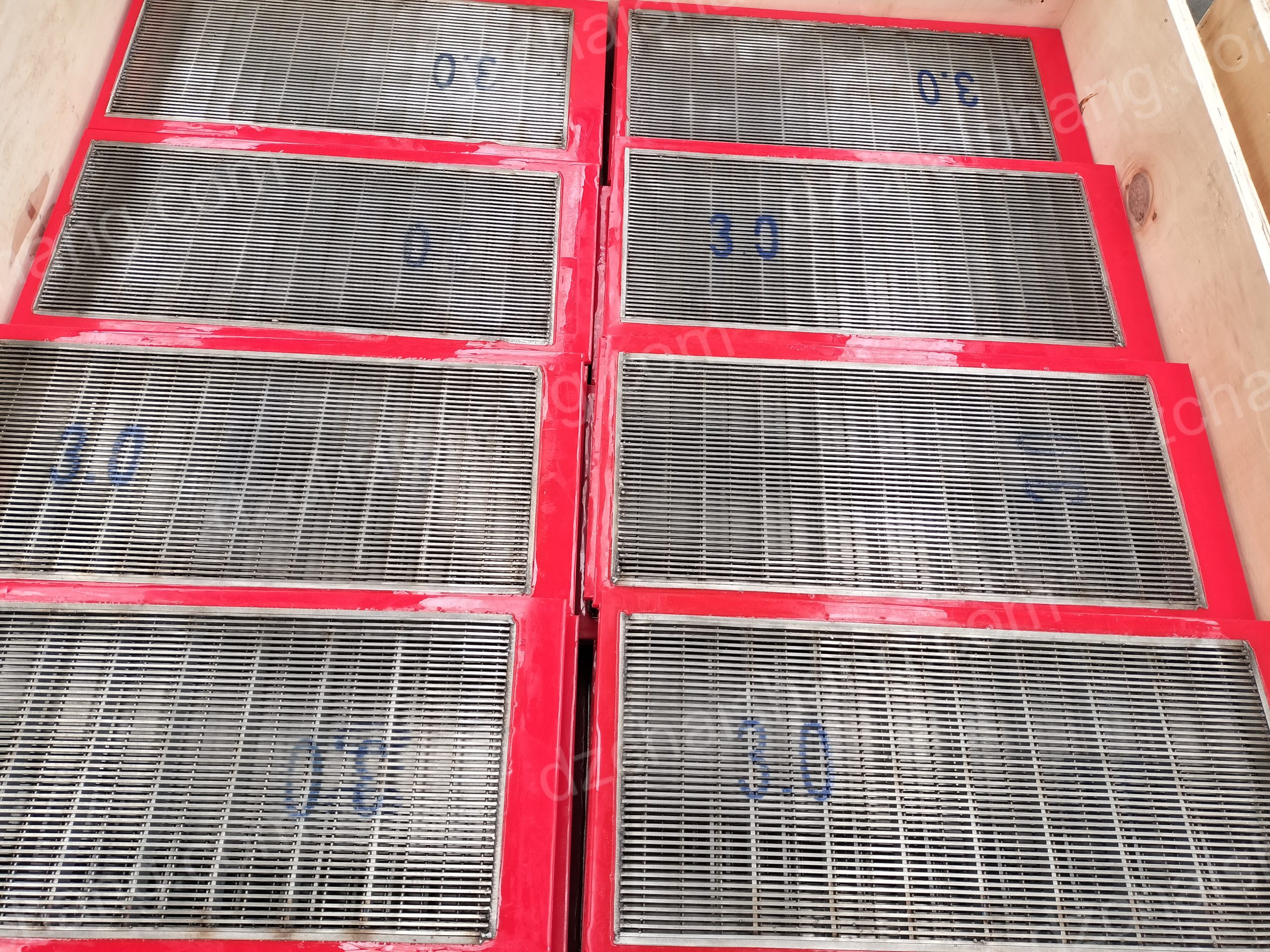

High-quality PU (polyurethane) vibrating screen panels are increasingly becoming the material of choice for vibrating sieve machines across various industries. Their unique properties offer distinct advantages over traditional screening materials like metal wire mesh, rubber, and others. Understanding these benefits in comparison to other materials can help in making informed decisions about the most suitable components for specific applications. Polyurethane is renowned for its exceptional durability and resistance to wear and tear. This is particularly important in industries such as mining, quarrying, and recycling where screens are subjected to severe conditions and abrasive materials. Unlike metal screens, PU vibrating screen panels are less likely to tear or break under heavy loads. This durability not only extends the lifespan of the screens but also reduces downtime and maintenance costs, ensuring continuous operation and productivity. Transitioning from durability to flexibility, PU panels outshine their counterparts by being highly flexible without losing their shape and structural integrity. This flexibility allows them to absorb impact better, reducing the likelihood of blinding and clogging, common issues in vibrating screen operations. Materials that tend to stick or peg in metal or rubber screens often flow more freely over polyurethane, enhancing screening efficiency and the quality of the final product. Moreover, the noise reduction capabilities of PU panels are significantly superior compared to metal screens. In environments where noise reduction is crucial for compliance with health and safety regulations, PU screens provide an excellent solution. They help in creating a safer and more comfortable working environment, which is an essential factor in workplaces striving to meet stringent occupational health standards. Another critical aspect to consider is the customization possibilities offered by polyurethane. PU vibrating screen panels can be manufactured in a wide range of hardness levels, which can be tailored to specific screening applications. Whether the requirement is for screening large, heavy particles or fine, delicate materials, there is a pu screen suitable for the task. This versatility is something that materials like metal and rubber cannot match, often requiring compromises in screen performance and lifespan. Environmental considerations also play a role in the selection of screening materials. PU is more environmentally friendly compared to some alternatives. It is non-toxic and does not emit harmful gases during production or disposal. Additionally, the long service life and recyclability of polyurethane contribute to its sustainability profile, making it a more attractive option for companies aiming to reduce their environmental impact.

In conclusion, while traditional materials like metal and rubber have been the mainstays for vibrating sieve machines, the advent of high-quality PU vibrating screen panels has set new standards in the industry. Their superior durability, flexibility, noise reduction capabilities, customization options, and environmental benefits provide a compelling case for their adoption. Industries looking to enhance their operational efficiency, reduce maintenance costs, and improve worker safety may find that switching to polyurethane screens offers significant advantages, making them a prudent choice in the long run.

Environmental considerations also play a role in the selection of screening materials. PU is more environmentally friendly compared to some alternatives. It is non-toxic and does not emit harmful gases during production or disposal. Additionally, the long service life and recyclability of polyurethane contribute to its sustainability profile, making it a more attractive option for companies aiming to reduce their environmental impact.

In conclusion, while traditional materials like metal and rubber have been the mainstays for vibrating sieve machines, the advent of high-quality PU vibrating screen panels has set new standards in the industry. Their superior durability, flexibility, noise reduction capabilities, customization options, and environmental benefits provide a compelling case for their adoption. Industries looking to enhance their operational efficiency, reduce maintenance costs, and improve worker safety may find that switching to polyurethane screens offers significant advantages, making them a prudent choice in the long run.