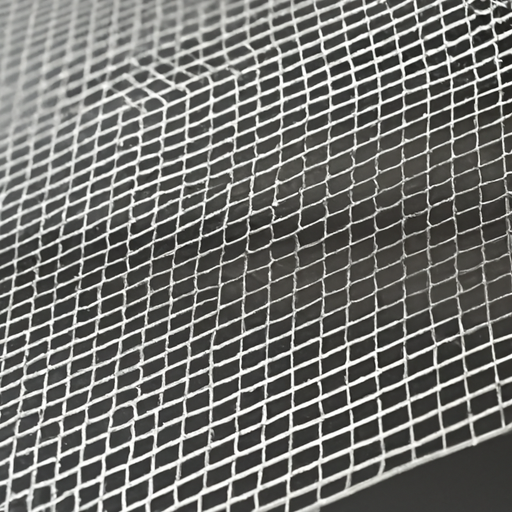

pu screen mesh

The Benefits of Using PU screen mesh in Industrial Applications polyurethane (PU) screen mesh is a versatile material that has gained popularity…

The Benefits of Using PU screen mesh in Industrial Applications

polyurethane (PU) screen mesh is a versatile material that has gained popularity in various industrial applications. Its unique properties make it an excellent choice for industries that require durable and efficient screening solutions. In this article, we will explore the benefits of using pu screen mesh in industrial applications. One of the key advantages of PU screen mesh is its exceptional abrasion resistance. This makes it ideal for industries that deal with abrasive materials such as mining, quarrying, and construction. Unlike traditional screen mesh materials like steel or rubber, PU screen mesh can withstand the constant wear and tear caused by abrasive particles. This not only extends the lifespan of the mesh but also reduces downtime and maintenance costs. Another benefit of PU screen mesh is its high tensile strength. It can withstand heavy loads and high impact forces without deforming or breaking. This makes it suitable for applications that involve heavy-duty screening, such as aggregate processing or recycling. The strong and resilient nature of PU screen mesh ensures that it can handle the demands of these industries, providing reliable and efficient screening performance.

In addition to its physical properties, PU screen mesh also offers superior screening efficiency. Its unique design allows for increased open area, which enhances the flow of materials through the screen. This results in improved screening accuracy and higher throughput rates. The open area design also prevents clogging and blinding, further enhancing the efficiency of the screening process. Industries that require precise and efficient screening, such as food processing or pharmaceuticals, can greatly benefit from the use of PU screen mesh.

Furthermore, PU screen mesh is resistant to chemicals and corrosion. It can withstand exposure to harsh chemicals, acids, and alkalis without deteriorating or losing its performance. This makes it suitable for industries that deal with corrosive materials or environments, such as chemical processing or wastewater treatment. The chemical resistance of PU screen mesh ensures its longevity and reliability in these demanding applications.

Lastly, PU screen mesh is easy to install and maintain. It can be quickly and securely attached to screening equipment, reducing downtime and installation costs. Its low maintenance requirements also contribute to cost savings in the long run. Regular cleaning and inspection are usually sufficient to keep PU screen mesh in optimal condition, ensuring consistent screening performance.

In conclusion, PU screen mesh offers numerous benefits for industrial applications. Its exceptional abrasion resistance, high tensile strength, flexibility, and superior screening efficiency make it an ideal choice for industries that require durable and efficient screening solutions. Additionally, its resistance to chemicals and corrosion, as well as its ease of installation and maintenance, further enhance its appeal. By choosing PU screen mesh, industries can improve their screening processes, reduce downtime and maintenance costs, and ultimately enhance their overall productivity.

In addition to its physical properties, PU screen mesh also offers superior screening efficiency. Its unique design allows for increased open area, which enhances the flow of materials through the screen. This results in improved screening accuracy and higher throughput rates. The open area design also prevents clogging and blinding, further enhancing the efficiency of the screening process. Industries that require precise and efficient screening, such as food processing or pharmaceuticals, can greatly benefit from the use of PU screen mesh.

Furthermore, PU screen mesh is resistant to chemicals and corrosion. It can withstand exposure to harsh chemicals, acids, and alkalis without deteriorating or losing its performance. This makes it suitable for industries that deal with corrosive materials or environments, such as chemical processing or wastewater treatment. The chemical resistance of PU screen mesh ensures its longevity and reliability in these demanding applications.

Lastly, PU screen mesh is easy to install and maintain. It can be quickly and securely attached to screening equipment, reducing downtime and installation costs. Its low maintenance requirements also contribute to cost savings in the long run. Regular cleaning and inspection are usually sufficient to keep PU screen mesh in optimal condition, ensuring consistent screening performance.

In conclusion, PU screen mesh offers numerous benefits for industrial applications. Its exceptional abrasion resistance, high tensile strength, flexibility, and superior screening efficiency make it an ideal choice for industries that require durable and efficient screening solutions. Additionally, its resistance to chemicals and corrosion, as well as its ease of installation and maintenance, further enhance its appeal. By choosing PU screen mesh, industries can improve their screening processes, reduce downtime and maintenance costs, and ultimately enhance their overall productivity.