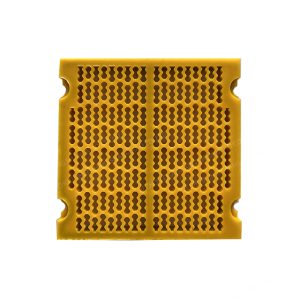

high frequency screen mesh

| Hole size | 0.05, 0.075, 0.1, 0.12, 0.125, 0.15, 0.18, 0.2, 0.23, 0.25, 0.3, 0.35, 0.4,, 0.5,, 0.6, 0.65, 0.7, 0.8, 0.85, 1, 1.2, 1.5, 2.5, 3, 6, 8 |

|---|---|

| Standard overall size | 1040*700, 1220*700, 1240*840, other size: width: 1000mm and 1200mm |

| Standard service life | 6~12 months |

| Customization | Available |

| Material | Polyurethane, pu, urethane |

- Satisfaction Guaranteed

- Accurate dimensions

- On-time delivery

Description

As a core part of a fine mesh vibrating screen, high frequency polyurethane screen mesh directly affect the screening efficiency and screening performance. A whole forming design makes it serves a longer life, anti-blinding, and non-leakage. It increases the mineral recovery rate, widely applied in metal and non-metallic minerals processing applications.

Polyurethane high frequency fine screen characteristics:

1. Opening rate is more than 32, high screening efficiency, and large processing capacity;

2. The screen uses a tapered hole design, which is conducive to the passage of materials and not easy to block the holes;

3. Good abrasion resistance and long service life, its service life is 5-10 times that of a steel sieve plate;

4. The maintenance workload is small, which can greatly reduce the maintenance volume and the loss of production and maintenance;

5. High cost performance, the price is 2-3 times of stainless steel screen, and the service life is 4-5 times;

6. Good humidity resistance, can work under the condition of water medium, and in the case of water and oil medium, the low friction coefficient of the material is more convenient for sieving, improving the screening rate, while reducing the friction coefficient, and increasing the service life;

7. Corrosion resistance, non-toxic and tasteless;

8. Energy-saving and noise-reduction, the proportion of polyurethane is small, and it is lighter than the steel sieve of the same model, to reduce the load on the sieve and reduce energy consumption.