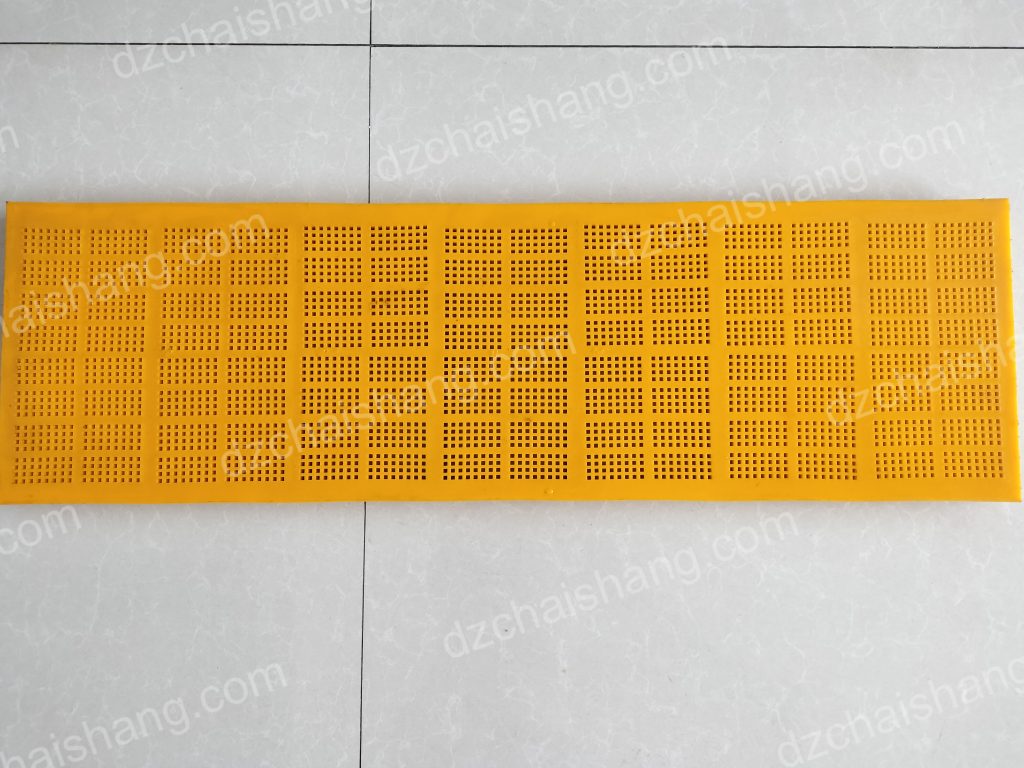

polyurethane panel,PU screen mesh,mining mesh

Product Name: Vibrating screen mesh Material: (PU)polyurethane/rubber type:modular/tensioned/high frequency etc. Popular Dimension: Can be customized. Customization: Available Standard service life: 6~12 months Delivery:…

Product Name: Vibrating screen mesh

Material: (PU)polyurethane/rubber

type:modular/tensioned/high frequency etc.

Popular Dimension: Can be customized.

Customization: Available

Standard service life: 6~12 months

Delivery: 15-45 days depending on the quantity

Email: Jackma@dzchaishang.com

WhatsApp/WeChat: 86-15621266667

polyurethane sieve plates are widely used in petrochemical, forest chemical, fertilizer, coal and other fields. It can screen various particulate materials, meet the requirements of material screening and grading, improve production efficiency and reduce production costs. In the future, the application field of polyurethane sieve plates will be more extensive.

Polyurethane sieve plates are a kind of efficient screening material with many advantages: polyurethane sieve plates have high compressive strength and wear resistance, and can be used for a long time in high-intensity working environments.

Compared with traditional metal sieve plates, it is lighter and easier to install and replace. At the same time, it has good elasticity and can effectively reduce vibration and noise.

It has high screening accuracy and screening efficiency, and can meet the screening requirements of different particle sizes. After a special manufacturing process, its surface also has a certain degree of adhesion, which can effectively avoid particle accumulation and blockage.

Because it has good elasticity and resilience, it can effectively reduce the consumption and impact energy of screening materials, thereby reducing energy consumption and environmental pollution.

In general, it has the advantages of being sturdy and durable, light and convenient, good screening effect, energy saving and environmental protection. Therefore, it is widely used in the screening of fly ash, petroleum, chemical and building materials industries.

polyurethane mesh panel,polyurethane mesh sieve,oscillating screen,modular sieve,modular screens,modular screening platform,modular plate size,modular plate price list,modular plate price,modular plate,modular panel board,modular mesh,high frequency screens for sale,mining mesh,high frequency screening,high frequency screen ,high frequency screen meaning,high frequency screen deck,high frequency screen capacity,PU screen mesh,high frequency screen astec,high frequency dewatering screen,good tensioned screen,fine screening,polyurethane panel,fine screen strainer,fine screen size,fine screen mesh stainless steel,dewatering screen working principle,dewatering screen mesh size,dewatering screen media,dewatering mesh,mining mesh,dewatering panel,PU screen mesh,aggregate screening plant,aggregate screening equipment,aggregate screener,aggregate screen sizes,PU screen mesh,aggregate screen shaker,aggregate screen plant,aggregate screen parts,aggregate screen mesh,aggregate screen manufacturers,polyurethane panel,aggregate screen for sale,aggregate screen deck,aggregate screen,PU mesh panel,polyurethane panel,PU coated wire screen,MESH MESH MESH,MESH MESH,vibrating screen,vibrating wire screen mesh,pu mesh screen,polyurethane sieve plate,polyurethane screen mesh plate,polyurethane fine screen mesh,mining mesh screen,mine vibrating sieving mesh,mining mesh,mine sludge dewatering mesh screen,mine sieve mesh,polyurethane panel,high quality vibrating screen,high frequency screen,Vibrating Mesh,VIBRATOR SCREEN SIEVE,VIBRATING SCREEN MESH,PU screen mesh,SCREEN SIEVE,polyurethane mining screen mesh sieve panel,polyurethane coated wire mesh,ore screen mesh,mining screening panels