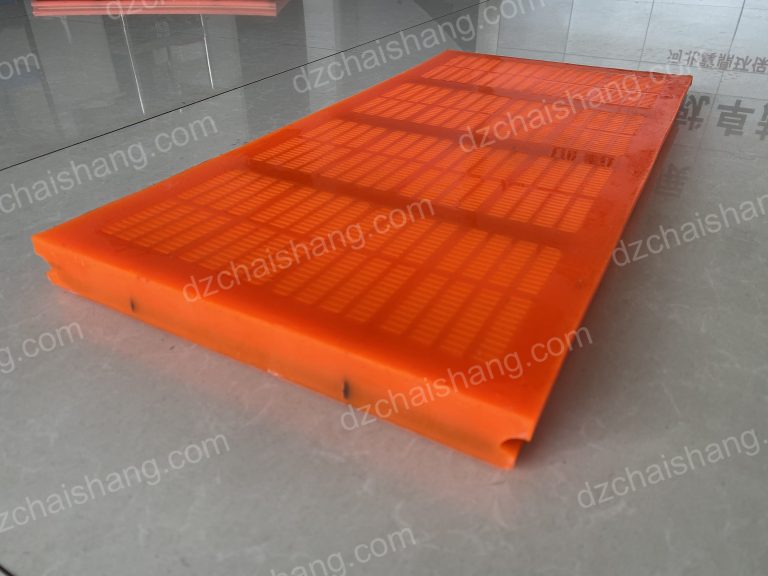

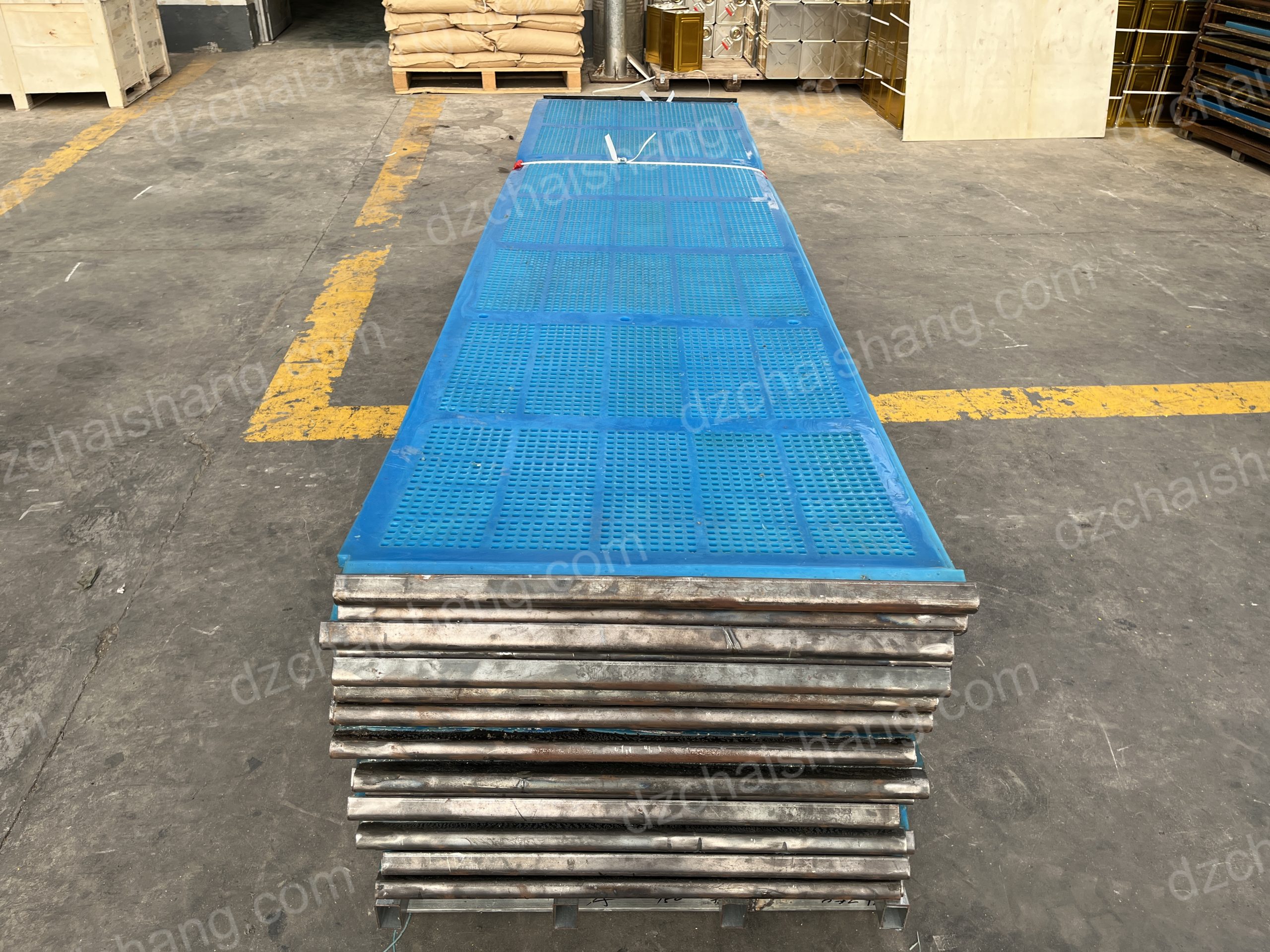

polyurethane molding screen,screen mesh for dewatering screen

How polyurethane molding screen mesh Can Improve dewatering screen Performance Polyurethane molding screen mesh is a type of screen mesh that is…

How polyurethane molding screen mesh Can Improve dewatering screen Performance

Polyurethane molding screen mesh is a type of screen mesh that is used in dewatering screens to improve performance. It is made from a combination of polyurethane and metal, and is designed to be more durable and efficient than traditional screen mesh. The polyurethane material is resistant to wear and tear, and the metal provides strength and rigidity. This combination of materials makes the mesh more effective at trapping and retaining particles, which improves the performance of the dewatering screen. The mesh is designed to be flexible and able to conform to the shape of the screen, allowing it to capture more particles. This flexibility also helps to reduce the amount of material that is lost during the dewatering process. The mesh is also designed to be resistant to clogging, which can reduce the amount of maintenance required to keep the screen running efficiently.

The mesh is also designed to be resistant to corrosion, which can help to extend the life of the screen. The mesh is also designed to be resistant to abrasion, which can help to reduce the amount of wear and tear on the screen. This can help to reduce the amount of maintenance required to keep the screen running efficiently.

The mesh is designed to be flexible and able to conform to the shape of the screen, allowing it to capture more particles. This flexibility also helps to reduce the amount of material that is lost during the dewatering process. The mesh is also designed to be resistant to clogging, which can reduce the amount of maintenance required to keep the screen running efficiently.

The mesh is also designed to be resistant to corrosion, which can help to extend the life of the screen. The mesh is also designed to be resistant to abrasion, which can help to reduce the amount of wear and tear on the screen. This can help to reduce the amount of maintenance required to keep the screen running efficiently.