polyurethane machine

The Benefits of Using a polyurethane machine in Manufacturing Processes Polyurethane is a versatile material that has become increasingly popular in various…

The Benefits of Using a polyurethane machine in Manufacturing Processes

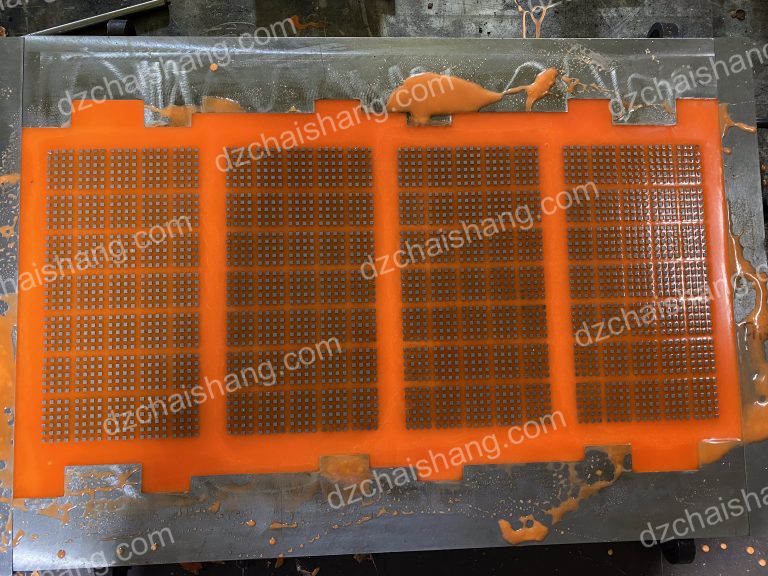

Polyurethane is a versatile material that has become increasingly popular in various manufacturing processes. Its unique properties make it an ideal choice for a wide range of applications, from automotive parts to furniture and even insulation. One of the key factors that contribute to the success of polyurethane in manufacturing is the use of a polyurethane machine. A polyurethane machine is a specialized piece of equipment that is designed to mix and dispense polyurethane materials. It is a crucial component in the manufacturing process, as it ensures the proper mixing and application of polyurethane, resulting in high-quality products.

One of the main benefits of using a polyurethane machine is its ability to provide precise control over the mixing process. Polyurethane materials consist of two main components: a polyol and an isocyanate. These components need to be mixed in the correct proportions to achieve the desired properties of the final product. A polyurethane machine allows manufacturers to accurately measure and control the ratio of these components, ensuring consistent and reliable results.

In addition to precise mixing control, a polyurethane machine also offers the advantage of adjustable flow rates. This means that manufacturers can easily adjust the amount of polyurethane being dispensed, depending on the specific requirements of the product being manufactured. This flexibility allows for greater customization and adaptability in the manufacturing process, resulting in products that meet the unique needs of customers.

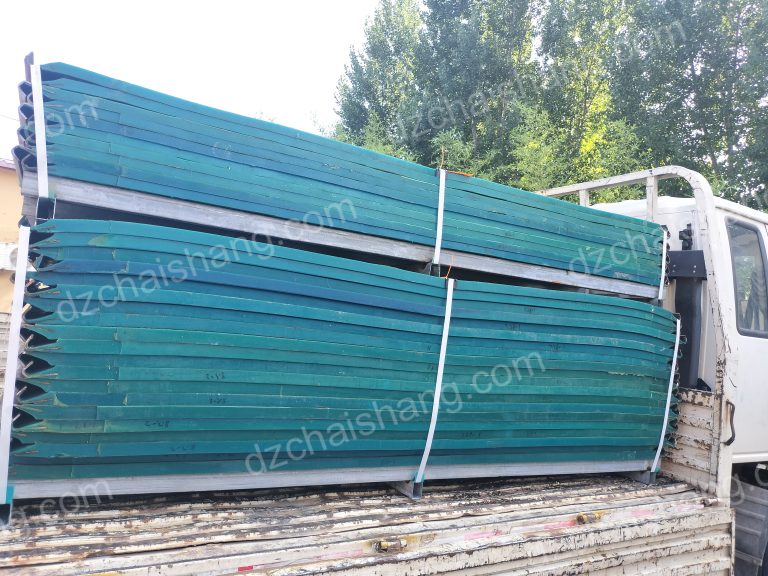

Another significant benefit of using a polyurethane machine is its efficiency. The automated nature of the machine reduces the need for manual labor, saving both time and money. With a polyurethane machine, manufacturers can produce a higher volume of products in a shorter amount of time, increasing overall productivity. This efficiency is particularly beneficial in large-scale manufacturing operations where speed and cost-effectiveness are crucial.

Furthermore, a polyurethane machine offers improved safety in the manufacturing process. The machine is designed to handle the mixing and dispensing of polyurethane materials, minimizing the risk of exposure to harmful chemicals. This is especially important considering that some isocyanates, a key component of polyurethane, can be hazardous if not handled properly. By using a polyurethane machine, manufacturers can ensure the safety of their workers and reduce the potential for accidents or health risks.

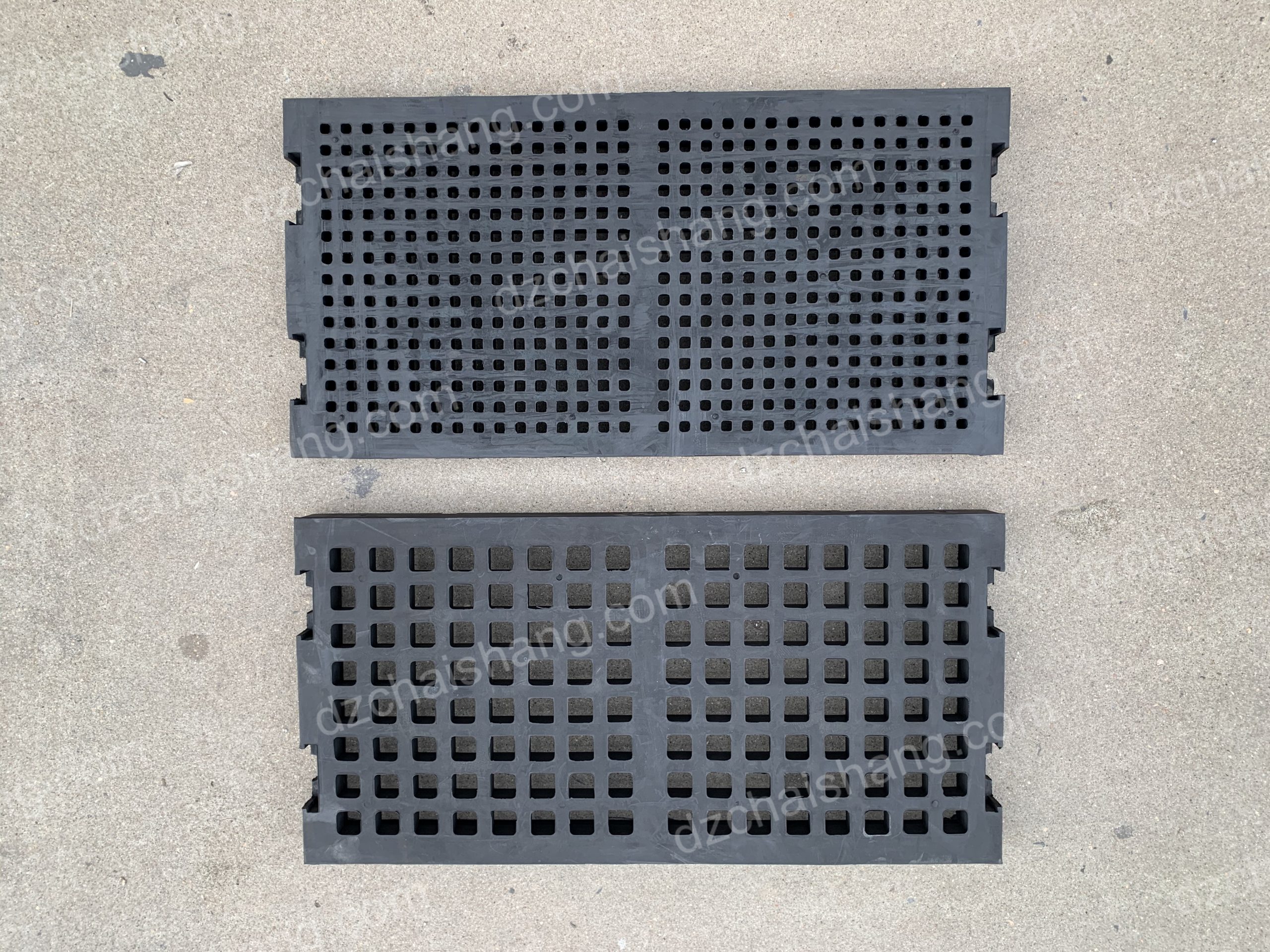

Lastly, a polyurethane machine contributes to the overall quality of the final product. The precise control over the mixing process, combined with the ability to adjust flow rates, ensures that the polyurethane is applied evenly and consistently. This results in products that have superior strength, durability, and aesthetics. Whether it is a car bumper, a mattress, or a piece of furniture, the use of a polyurethane machine guarantees that the end product meets the highest standards of quality.

One of the main benefits of using a polyurethane machine is its ability to provide precise control over the mixing process. Polyurethane materials consist of two main components: a polyol and an isocyanate. These components need to be mixed in the correct proportions to achieve the desired properties of the final product. A polyurethane machine allows manufacturers to accurately measure and control the ratio of these components, ensuring consistent and reliable results.

In addition to precise mixing control, a polyurethane machine also offers the advantage of adjustable flow rates. This means that manufacturers can easily adjust the amount of polyurethane being dispensed, depending on the specific requirements of the product being manufactured. This flexibility allows for greater customization and adaptability in the manufacturing process, resulting in products that meet the unique needs of customers.

Another significant benefit of using a polyurethane machine is its efficiency. The automated nature of the machine reduces the need for manual labor, saving both time and money. With a polyurethane machine, manufacturers can produce a higher volume of products in a shorter amount of time, increasing overall productivity. This efficiency is particularly beneficial in large-scale manufacturing operations where speed and cost-effectiveness are crucial.

Furthermore, a polyurethane machine offers improved safety in the manufacturing process. The machine is designed to handle the mixing and dispensing of polyurethane materials, minimizing the risk of exposure to harmful chemicals. This is especially important considering that some isocyanates, a key component of polyurethane, can be hazardous if not handled properly. By using a polyurethane machine, manufacturers can ensure the safety of their workers and reduce the potential for accidents or health risks.

Lastly, a polyurethane machine contributes to the overall quality of the final product. The precise control over the mixing process, combined with the ability to adjust flow rates, ensures that the polyurethane is applied evenly and consistently. This results in products that have superior strength, durability, and aesthetics. Whether it is a car bumper, a mattress, or a piece of furniture, the use of a polyurethane machine guarantees that the end product meets the highest standards of quality.