horizonal screen plate,flip flop mesh panel,flip flop screen media

Exploring the Functionality and Benefits of Horizontal screen Plates Horizontal screen plates, flip flop mesh panels, and flip flop screen media are…

Exploring the Functionality and Benefits of Horizontal screen Plates

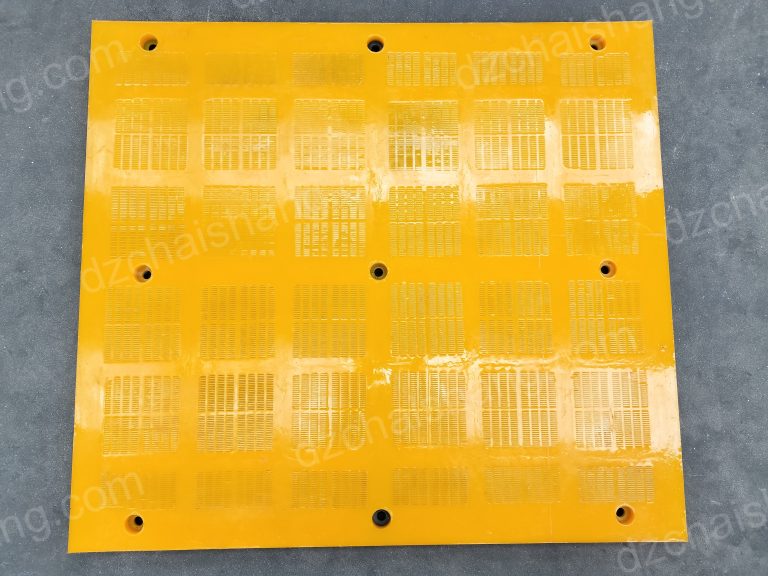

Horizontal screen plates, flip flop mesh panels, and flip flop screen media are integral components in the mining, recycling, and waste management industries. These innovative tools have revolutionized the way materials are sorted and processed, offering a plethora of benefits that enhance efficiency, productivity, and sustainability. Horizontal screen plates are primarily used in screening machines for material classification. They are designed to handle a wide range of materials, from fine particles to large rocks. The horizontal orientation of these plates allows for a more efficient screening process as it increases the surface area for material contact. This design feature ensures that materials are thoroughly sifted and sorted, reducing the likelihood of unwanted materials slipping through.

The functionality of horizontal screen plates is further enhanced when paired with flip flop mesh panels. These panels are characterized by their unique ability to ‘flip’ or ‘flop’, creating a non-linear motion that effectively separates materials based on size and density. The flip flop motion is particularly useful in handling wet and sticky materials that often clog conventional screens. By preventing clogging, flip flop mesh panels significantly reduce downtime for cleaning and maintenance, thereby increasing overall productivity.

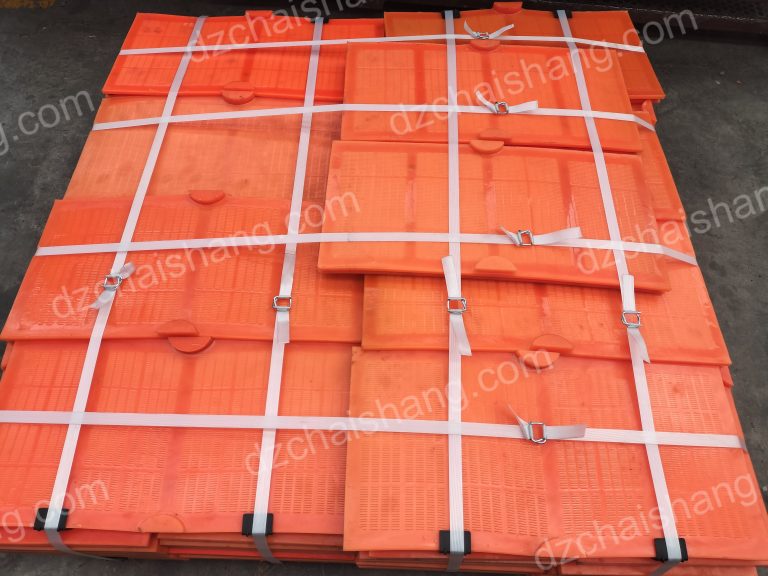

Flip flop screen media, on the other hand, refers to the type of screen used in conjunction with the flip flop mesh panels. This media is typically made from highly durable polyurethane material, which is resistant to wear and tear, ensuring a longer lifespan compared to traditional steel screens. The resilience of polyurethane also allows the screen media to withstand the vigorous flip flop motion without compromising its structural integrity.

The combination of horizontal screen plates, flip flop mesh panels, and flip flop screen media offers numerous benefits. Firstly, they provide a high screening efficiency. The horizontal screen plates offer a larger screening area, while the flip flop motion ensures thorough material separation. This results in a higher yield of desired materials and less waste.

Secondly, these components are highly versatile. They can handle a wide range of materials, from dry and fine particles to wet and sticky substances. This versatility makes them suitable for various industries, including mining, recycling, and waste management.

Thirdly, they are cost-effective. The durability of the flip flop screen media reduces the need for frequent replacements, while the efficiency of the horizontal screen plates and flip flop mesh panels minimizes waste and maximizes yield. This translates into significant cost savings in the long run.

Lastly, these components contribute to sustainability. By improving material recovery and reducing waste, they help industries minimize their environmental impact. Moreover, the durability of the flip flop screen media means less frequent replacements, which reduces the demand for raw materials and energy for production.

In conclusion, horizontal screen plates, flip flop mesh panels, and flip flop screen media are innovative tools that offer a multitude of benefits. Their functionality and benefits make them indispensable in industries that require efficient and effective material separation. As technology continues to advance, it is expected that these components will continue to evolve, offering even greater efficiency, versatility, and sustainability.

Horizontal screen plates are primarily used in screening machines for material classification. They are designed to handle a wide range of materials, from fine particles to large rocks. The horizontal orientation of these plates allows for a more efficient screening process as it increases the surface area for material contact. This design feature ensures that materials are thoroughly sifted and sorted, reducing the likelihood of unwanted materials slipping through.

The functionality of horizontal screen plates is further enhanced when paired with flip flop mesh panels. These panels are characterized by their unique ability to ‘flip’ or ‘flop’, creating a non-linear motion that effectively separates materials based on size and density. The flip flop motion is particularly useful in handling wet and sticky materials that often clog conventional screens. By preventing clogging, flip flop mesh panels significantly reduce downtime for cleaning and maintenance, thereby increasing overall productivity.

Flip flop screen media, on the other hand, refers to the type of screen used in conjunction with the flip flop mesh panels. This media is typically made from highly durable polyurethane material, which is resistant to wear and tear, ensuring a longer lifespan compared to traditional steel screens. The resilience of polyurethane also allows the screen media to withstand the vigorous flip flop motion without compromising its structural integrity.

The combination of horizontal screen plates, flip flop mesh panels, and flip flop screen media offers numerous benefits. Firstly, they provide a high screening efficiency. The horizontal screen plates offer a larger screening area, while the flip flop motion ensures thorough material separation. This results in a higher yield of desired materials and less waste.

Secondly, these components are highly versatile. They can handle a wide range of materials, from dry and fine particles to wet and sticky substances. This versatility makes them suitable for various industries, including mining, recycling, and waste management.

Thirdly, they are cost-effective. The durability of the flip flop screen media reduces the need for frequent replacements, while the efficiency of the horizontal screen plates and flip flop mesh panels minimizes waste and maximizes yield. This translates into significant cost savings in the long run.

Lastly, these components contribute to sustainability. By improving material recovery and reducing waste, they help industries minimize their environmental impact. Moreover, the durability of the flip flop screen media means less frequent replacements, which reduces the demand for raw materials and energy for production.

In conclusion, horizontal screen plates, flip flop mesh panels, and flip flop screen media are innovative tools that offer a multitude of benefits. Their functionality and benefits make them indispensable in industries that require efficient and effective material separation. As technology continues to advance, it is expected that these components will continue to evolve, offering even greater efficiency, versatility, and sustainability.