fabrikkvibrator strammet polyuretansikt, ristemaskin horisontal gummimedieleverandør

Utforsk fordelene med fabrikkvibratorspennede polyuretansikter og horisontale gummimedieleverandører Fabrikkvibratorspennede polyuretansikter og horisontale gummimedieleverandører spiller en avgjørende rolle i ulike bransjer, inkludert gruvedrift,…

Utforsk fordelene med fabrikkvibratorspennede polyuretansikter og horisontale gummimedieleverandører

Fabrikkvibratorspennede polyuretansikter og horisontale gummimedieleverandører spiller en avgjørende rolle i ulike bransjer, inkludert gruvedrift, landbruk og konstruksjon. Disse materialene er essensielle for effektiv og effektiv separering og klassifisering av materialer, som er en kritisk prosess i mange produksjons- og produksjonsoperasjoner.

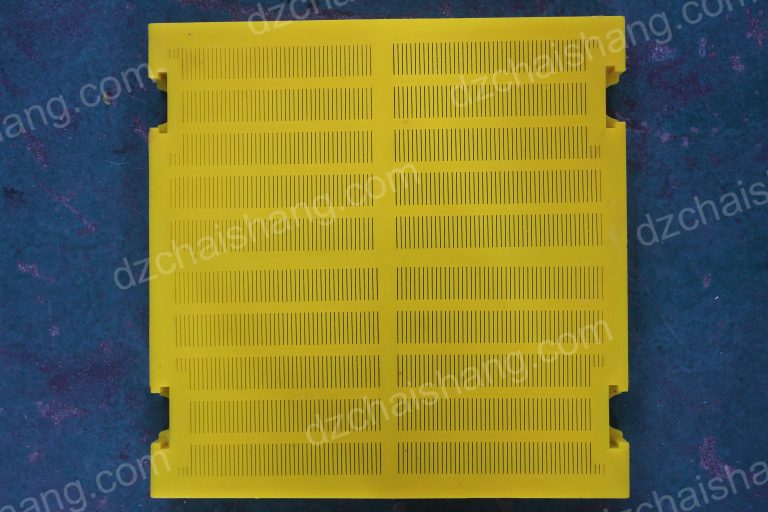

Polyuretansikter, spesielt de som strammes med fabrikkvibratorer, gir flere fordeler i forhold til tradisjonelle siktingsmaterialer. En av de viktigste fordelene er deres eksepsjonelle holdbarhet og motstand mot slitasje. Polyuretan er et robust materiale som tåler tøffe forhold og slitende materialer, noe som gjør det ideelt for bruk i tunge applikasjoner. Denne holdbarheten forlenger ikke bare levetiden til sikten, men reduserer også behovet for hyppige utskiftninger, noe som til slutt sparer kostnader i det lange løp.

Overgang til horisontale gummimedier, er disse materialene mye brukt i skjermingsapplikasjoner der støyreduksjon og slagfasthet er viktig. Gummimedier er mykere sammenlignet med metall- eller plastalternativer, noe som bidrar til å absorbere påvirkningen fra materialene som behandles. Dette reduserer ikke bare støynivået knyttet til silingsprosessen, men minimerer også slitasjen på selve silutstyret.

Horisontale gummimedier er spesielt fordelaktige i applikasjoner der materialet som behandles er utsatt for brudd eller nedbrytning. Gummiens dempende effekt bidrar til å bevare materialets integritet, og sikrer at det forblir i ønsket tilstand for videre bearbeiding eller sluttbruk. Dette er spesielt viktig i bransjer som matforedling eller farmasøytiske produkter, hvor det er viktig å opprettholde kvaliteten på produktet.

I tillegg tilbyr leverandører av horisontale gummimedier en rekke tilpasningsalternativer for å passe spesifikke bruksbehov. Dette inkluderer varierende nivåer av hardhet, tykkelse og størrelse, noe som gir mulighet for en skreddersydd løsning som maksimerer effektivitet og effektivitet. Fleksibiliteten i tilpasning betyr også at gummimedier kan tilpasses til å fungere med eksisterende utstyr, noe som reduserer behovet for kostbare modifikasjoner eller oppgraderinger.

Avslutningsvis gir fabrikkvibratorstramte polyuretansikter og leverandører av horisontale gummimedier viktige komponenter for materialseparasjon og klassifisering i ulike bransjer. Holdbarheten og effektiviteten til polyuretansikter, kombinert med støyreduksjonen og slagfastheten til horisontale gummimedier, gjør disse materialene uvurderlige for å sikre kvaliteten og konsistensen til sluttproduktet. Ved å velge riktig leverandør og tilpasningsalternativer kan bedrifter optimere sine screeningsprosesser, redusere driftskostnader og opprettholde et konkurransefortrinn i sine respektive markeder.