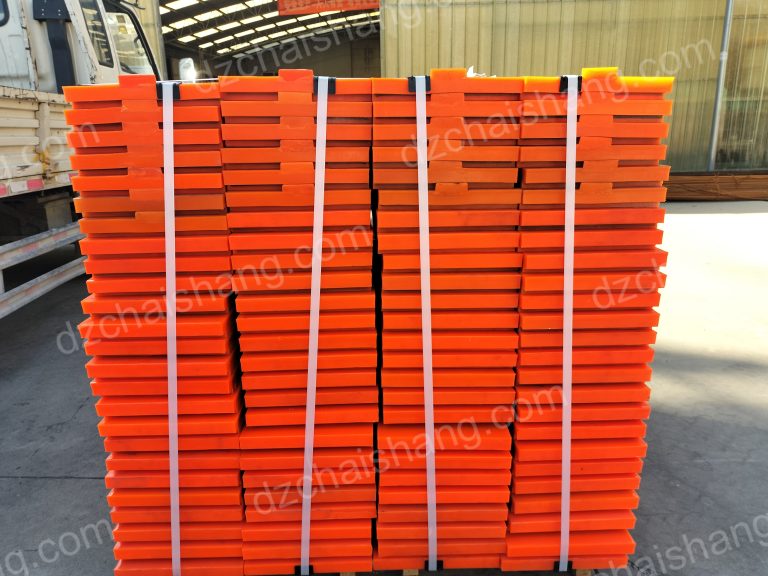

Manufacturer PU panel minerial,high frequency PU sieveprovider Dewatering

How PU Panels Can Improve Your Manufacturing Process PU panels are an innovative and cost-effective solution for improving the efficiency of manufacturing…

How PU Panels Can Improve Your Manufacturing Process

PU panels are an innovative and cost-effective solution for improving the efficiency of manufacturing processes. These panels are made from a unique combination of polyurethane and polyester, which makes them highly durable and resistant to wear and tear. This makes them ideal for use in a variety of manufacturing processes, from automotive to aerospace.

The panels are designed to be lightweight and flexible, allowing them to be easily installed in a variety of locations. This makes them ideal for use in areas where space is limited, such as in tight corners or narrow spaces. Additionally, the panels are designed to be resistant to corrosion, making them suitable for use in harsh environments.

The panels are also designed to be highly resistant to heat and cold, making them suitable for use in a variety of temperatures. This makes them ideal for use in manufacturing processes that require extreme temperatures, such as in the production of plastics or metals. Additionally, the panels are designed to be resistant to chemicals, making them suitable for use in processes that involve the use of hazardous materials.

The panels are also designed to be highly resistant to abrasion, making them suitable for use in processes that involve the use of abrasive materials. This makes them ideal for use in processes that involve the use of grinding or sanding. Additionally, the panels are designed to be resistant to fire, making them suitable for use in processes that involve the use of flammable materials.

Overall, PU panels are an excellent solution for improving the efficiency of manufacturing processes. They are lightweight, flexible, and resistant to wear and tear, making them ideal for use in a variety of applications. Additionally, they are resistant to corrosion, heat, cold, chemicals, and abrasion, making them suitable for use in a variety of processes. As such, they are an ideal solution for improving the efficiency of manufacturing processes.

The Benefits of high frequency PU Sieve Provider Dewatering for Manufacturers