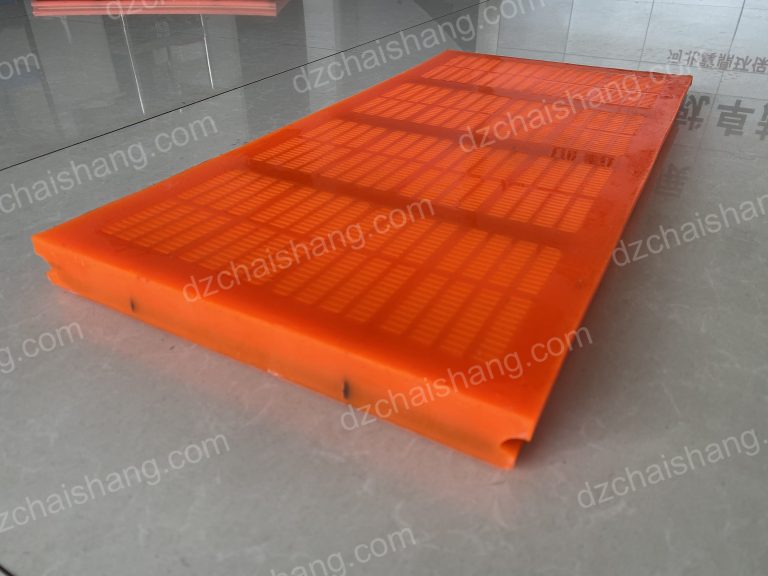

mining vibrating polyurethane screen,mining screen

Benefits of Using polyurethane screens in mining Operations Mining operations require efficient and reliable equipment to ensure the extraction of valuable minerals….

Benefits of Using polyurethane screens in mining Operations

Mining operations require efficient and reliable equipment to ensure the extraction of valuable minerals. One crucial component of this equipment is the vibrating screen, which is used to separate materials based on size. In recent years, polyurethane screens have become increasingly popular in the mining industry due to their numerous benefits. Polyurethane screens offer several advantages over traditional steel screens. One of the main benefits is their durability. Polyurethane is a tough and resilient material that can withstand the harsh conditions of mining operations, including abrasive materials and high impact forces. This durability translates to longer screen life and reduced maintenance costs, making polyurethane screens a cost-effective choice for mining companies. In addition to their durability, polyurethane screens are also highly flexible. This flexibility allows them to absorb impact and reduce the risk of damage, prolonging the lifespan of the screen. Polyurethane screens can also be manufactured with various opening sizes and shapes to suit different screening applications, providing mining companies with greater flexibility in their operations. Another key advantage of polyurethane screens is their superior screening efficiency. The flexible nature of polyurethane allows for greater vibration amplitude, resulting in improved screening performance and higher throughput. This increased efficiency can lead to higher productivity and lower operating costs for mining operations. Furthermore, polyurethane screens are lightweight and easy to install, reducing labor costs and installation time. Their lightweight construction also makes them easier to handle and transport, contributing to overall operational efficiency. Additionally, polyurethane screens are corrosion-resistant, making them suitable for use in wet and corrosive environments commonly found in mining operations.

Overall, the benefits of using polyurethane screens in mining operations are clear. Their durability, flexibility, screening efficiency, self-cleaning properties, and ease of installation make them a superior choice for companies looking to improve their screening processes. By investing in polyurethane screens, mining companies can increase productivity, reduce maintenance costs, and enhance overall operational efficiency.

In conclusion, polyurethane screens offer numerous advantages that make them an ideal choice for mining operations. Their durability, flexibility, screening efficiency, self-cleaning properties, and ease of installation set them apart from traditional steel screens. By choosing polyurethane screens, mining companies can improve their screening processes, increase productivity, and reduce operating costs. With these benefits in mind, it is clear that polyurethane screens are a valuable investment for any mining operation looking to optimize its screening equipment.

Furthermore, polyurethane screens are lightweight and easy to install, reducing labor costs and installation time. Their lightweight construction also makes them easier to handle and transport, contributing to overall operational efficiency. Additionally, polyurethane screens are corrosion-resistant, making them suitable for use in wet and corrosive environments commonly found in mining operations.

Overall, the benefits of using polyurethane screens in mining operations are clear. Their durability, flexibility, screening efficiency, self-cleaning properties, and ease of installation make them a superior choice for companies looking to improve their screening processes. By investing in polyurethane screens, mining companies can increase productivity, reduce maintenance costs, and enhance overall operational efficiency.

In conclusion, polyurethane screens offer numerous advantages that make them an ideal choice for mining operations. Their durability, flexibility, screening efficiency, self-cleaning properties, and ease of installation set them apart from traditional steel screens. By choosing polyurethane screens, mining companies can improve their screening processes, increase productivity, and reduce operating costs. With these benefits in mind, it is clear that polyurethane screens are a valuable investment for any mining operation looking to optimize its screening equipment.