UGOL ROSSII & MINING pu sieve mesh,pu shaker screen,pu screen mesh machines

Understanding the Role of pu sieve mesh in mining Operations UGOL ROSSII & MINING pu sieve mesh, pu shaker screen, pu screen…

Understanding the Role of pu sieve mesh in mining Operations

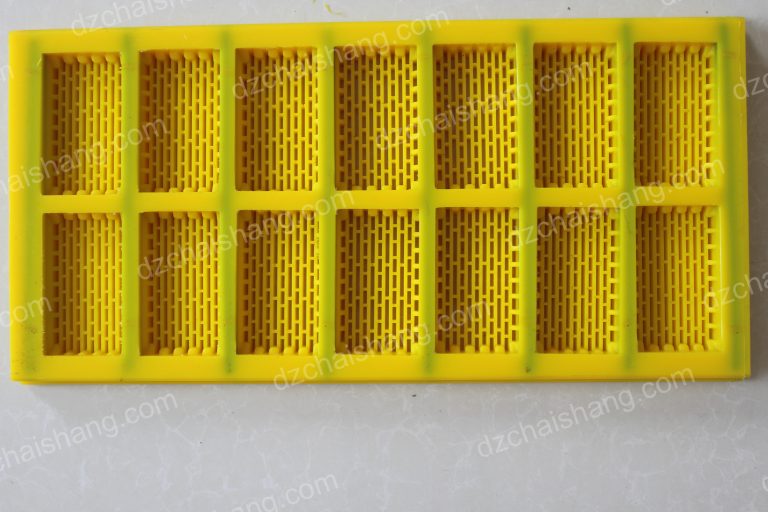

UGOL ROSSII & MINING pu sieve mesh, pu shaker screen, PU screen mesh machines have become integral components in modern mining operations, revolutionizing the way materials are processed and sorted. polyurethane (PU) sieve mesh offers numerous advantages over traditional metal mesh screens, making it a preferred choice for many mining companies worldwide.

One of the key benefits of PU sieve mesh is its durability. Unlike metal screens that are prone to corrosion and wear over time, PU sieve mesh is highly resistant to abrasion and chemical deterioration. This resilience ensures prolonged service life, reducing downtime and maintenance costs for mining operations. Additionally, PU sieve mesh is lightweight, making it easier to handle and install, further streamlining the screening process.

In addition to its durability, PU sieve mesh offers superior screening performance. Its unique properties allow for efficient particle separation, resulting in higher throughput and increased productivity. The elasticity of PU sieve mesh enables it to effectively bounce back from impacts, preventing blinding and clogging commonly associated with traditional screens. This ensures consistent screening efficiency, even in the most demanding mining conditions.

Furthermore, PU sieve mesh provides enhanced flexibility and versatility in screening applications. Its modular design allows for easy customization to meet specific sizing and material requirements. Mining operations can choose from a range of aperture sizes and screen configurations to achieve optimal performance for their processing needs. Whether screening coarse aggregates or fine particles, PU sieve mesh delivers precision and reliability, improving overall process efficiency.

Another significant advantage of PU sieve mesh is its environmental sustainability. Unlike metal screens that generate noise and vibration during operation, PU sieve mesh dampens sound and reduces vibration levels, creating a quieter and more environmentally friendly work environment. Additionally, PU sieve mesh is recyclable, contributing to the circular economy by minimizing waste and resource consumption in mining operations.

Moreover, PU sieve mesh offers cost-effective solutions for mining companies. While initial investment may be slightly higher than traditional metal screens, the long-term benefits far outweigh the initial costs. With its extended service life, reduced maintenance requirements, and improved screening performance, PU sieve mesh delivers significant cost savings over its operational lifespan.

In conclusion, PU sieve mesh plays a crucial role in modern mining operations, offering durability, performance, flexibility, and sustainability. Its ability to withstand harsh mining conditions while delivering efficient screening performance makes it an indispensable asset for processing operations worldwide. As mining companies continue to prioritize efficiency, productivity, and environmental stewardship, PU sieve mesh stands out as a reliable solution for optimizing material processing and sorting processes.

Exploring the Benefits of PU Shaker Screens for UGOL ROSSII Applications

UGOL ROSSII & MINING, one of the premier events in the mining industry, showcases the latest technologies and innovations. Among these innovations are PU sieve mesh and shaker screen machines, which have been gaining attention for their benefits in various mining applications. PU, or polyurethane, shaker screens offer distinct advantages over traditional materials like steel or rubber. In this article, we will delve into the benefits of PU shaker screens specifically tailored for UGOL ROSSII applications.

One of the primary advantages of PU shaker screens is their durability. PU is known for its resilience and resistance to wear and tear, making it ideal for the rigorous conditions encountered in mining operations. Unlike traditional materials that may degrade over time, PU shaker screens maintain their integrity, resulting in longer service life and reduced maintenance costs.

Moreover, PU shaker screens offer superior screening performance. The material’s elasticity allows for efficient vibration transmission, facilitating the separation of materials with precision. This enhanced screening capability improves the overall efficiency of mining operations by ensuring accurate separation of valuable minerals from waste materials.

Another significant benefit of PU shaker screens is their versatility. They can be customized to meet the specific requirements of different mining applications. Whether screening coal, ores, or aggregates, PU shaker screens can be tailored to achieve optimal results, enhancing productivity and profitability for mining companies.

Furthermore, PU shaker screens contribute to environmental sustainability in mining operations. PU is a recyclable material, reducing the environmental footprint associated with mining activities. Additionally, the efficiency of PU shaker screens results in less material wastage, minimizing the impact on natural resources.

In terms of maintenance, PU shaker screens are easy to clean and maintain. Their smooth surface prevents material buildup, reducing downtime for cleaning and increasing operational efficiency. With simple maintenance procedures, mining companies can maximize the uptime of their equipment, ensuring continuous production.

Additionally, PU shaker screens offer improved safety in mining operations. Their lightweight construction reduces the risk of accidents during installation and maintenance activities. Furthermore, the absence of sharp edges or protrusions minimizes the potential for workplace injuries, prioritizing the well-being of mining personnel.

Incorporating PU shaker screens into UGOL ROSSII applications can lead to significant cost savings for mining companies. The durability, efficiency, and versatility of PU shaker screens result in lower operational costs and increased profitability. By investing in high-quality PU shaker screens, mining companies can optimize their processes and stay competitive in the dynamic mining industry.

In conclusion, PU shaker screens offer a myriad of benefits for UGOL ROSSII applications in the mining sector. From enhanced durability and screening performance to environmental sustainability and cost savings, PU shaker screens are revolutionizing the way mining operations are conducted. As the mining industry continues to evolve, PU shaker screens stand out as a reliable and efficient solution for achieving optimal results in UGOL ROSSII applications.