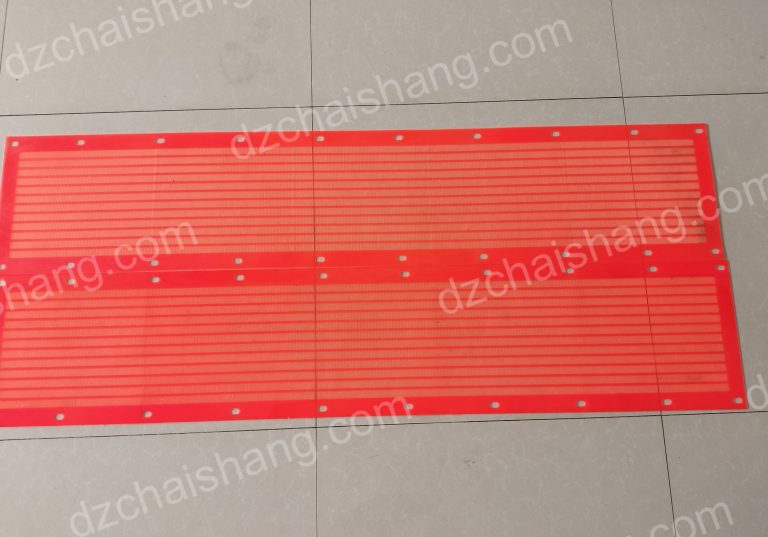

Urethane trommel panel Made to order Ore

Benefits of Using urethane Trommel Panels for Ore Processing Urethane trommel panels are a popular choice for ore processing operations due to…

Benefits of Using urethane Trommel Panels for Ore Processing

Urethane trommel panels are a popular choice for ore processing operations due to their durability, efficiency, and customizability. These panels are made to order, ensuring a perfect fit for each specific trommel screen. This tailored approach allows for optimal performance and maximum productivity in ore processing plants.

One of the key benefits of using urethane trommel panels is their exceptional wear resistance. Urethane is a tough and resilient material that can withstand the harsh conditions of ore processing, including abrasion, impact, and corrosion. This durability ensures a longer lifespan for the panels, reducing the need for frequent replacements and maintenance.

In addition to their durability, urethane trommel panels are also known for their high screening efficiency. The smooth surface of urethane allows for easy material flow and prevents clogging, resulting in a more efficient screening process. This increased efficiency leads to higher throughput and improved overall performance of the ore processing plant.

Another advantage of urethane trommel panels is their customizability. These panels can be tailored to meet the specific requirements of each ore processing operation, including size, shape, and aperture size. This customization allows for a more precise screening process, ensuring that the desired ore size is achieved with minimal waste.

Furthermore, urethane trommel panels are easy to install and maintain. Their lightweight design makes them easy to handle and replace, reducing downtime and labor costs. Additionally, urethane is a low-maintenance material that is resistant to chemicals and UV exposure, further extending the lifespan of the panels.

Overall, the benefits of using urethane trommel panels for ore processing are clear. Their durability, efficiency, and customizability make them an ideal choice for maximizing productivity and performance in ore processing plants. By investing in urethane trommel panels, operators can expect a reliable and cost-effective solution for their screening needs.

In conclusion, urethane trommel panels offer a range of benefits that make them a superior choice for ore processing operations. Their durability, efficiency, and customizability set them apart from other screening options, providing a reliable and long-lasting solution for ore processing plants. With their exceptional wear resistance and high screening efficiency, urethane trommel panels are sure to enhance the performance of any ore processing operation.

Customization Options for Urethane Trommel Panels in Ore Processing Operations

Urethane trommel panels are an essential component in ore processing operations, as they play a crucial role in separating valuable minerals from waste material. These panels are designed to withstand the harsh conditions of the mining industry, providing durability and efficiency in the processing of ores. One of the key advantages of urethane trommel panels is their ability to be customized to meet the specific needs of each ore processing operation.

Customization options for urethane trommel panels are vast, allowing for a tailored solution that maximizes efficiency and productivity. From size and shape to aperture size and panel thickness, every aspect of the panel can be customized to ensure optimal performance. This level of customization is essential in achieving the desired results in ore processing operations, as each ore deposit is unique and requires a tailored approach to maximize recovery rates.

When it comes to size and shape, urethane trommel panels can be custom-made to fit any trommel screen, ensuring a perfect fit and seamless integration into the processing plant. This customization option eliminates the need for modifications or adjustments, saving time and resources in the installation process. Additionally, custom sizing allows for maximum screen coverage, minimizing the risk of material bypass and improving overall efficiency.

Aperture size is another critical customization option for urethane trommel panels, as it directly impacts the efficiency of the screening process. By selecting the appropriate aperture size, operators can control the size of the material that passes through the screen, ensuring that only the desired particles are collected. This level of control is essential in achieving the desired product quality and maximizing the recovery of valuable minerals.

Panel thickness is also a customizable feature of urethane trommel panels, with options ranging from standard thickness to heavy-duty panels for high-wear applications. Thicker panels provide increased durability and longevity, making them ideal for processing abrasive ores or operating in high-impact environments. By selecting the appropriate panel thickness, operators can extend the lifespan of their trommel panels and reduce maintenance costs over time.

In addition to these key customization options, urethane trommel panels can also be tailored to meet specific processing requirements, such as material type, feed rate, and operating conditions. By working closely with a reputable manufacturer, operators can design a custom solution that meets their unique needs and delivers optimal performance in their ore processing operation.

Overall, customization options for urethane trommel panels offer a tailored solution for ore processing operations, allowing operators to maximize efficiency, productivity, and profitability. By selecting the right size, shape, aperture size, and panel thickness, operators can achieve the desired results in their processing plant and optimize the recovery of valuable minerals. With the ability to customize every aspect of the panel, urethane trommel panels are a versatile and effective solution for ore processing operations.