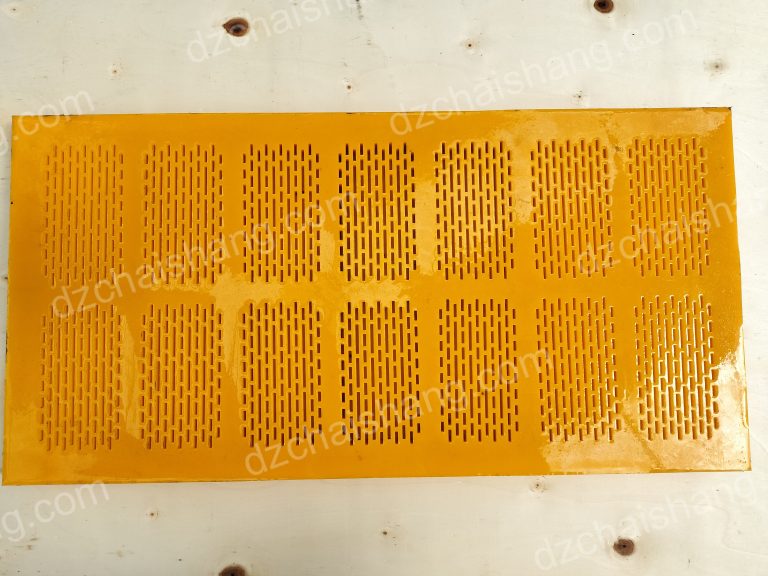

Shaker Setaccio di tensione in uretano Realizzato su ordinazione, pannello in uretano tensionato con vibratore in fabbrica

Esplorazione del processo di personalizzazione dei setacci tensionatori in uretano con agitatore nei pannelli in uretano tensionati con vibratore di fabbrica L’industria…

Esplorazione del processo di personalizzazione dei setacci tensionatori in uretano con agitatore nei pannelli in uretano tensionati con vibratore di fabbrica

L’industria manifatturiera è in continua evoluzione, con l’introduzione di nuove tecnologie e materiali per migliorare l’efficienza e la qualità dei prodotti. Una di queste innovazioni è il vaglio di tensione in uretano dello shaker, un componente fondamentale nei pannelli di uretano tensionati con vibratore di fabbrica. Questi pannelli sono ampiamente utilizzati in vari settori, tra cui l’estrazione mineraria, l’edilizia e il riciclaggio, per la loro durata, flessibilità e resistenza all’usura superiori. Questo articolo esplora il processo di personalizzazione dei setacci tensionatori in uretano con agitatore nei pannelli in uretano tensionati con vibratore di fabbrica.

Il processo inizia con la selezione del giusto materiale uretanico. L’uretano, un tipo di polimero, viene scelto per le sue proprietà eccezionali come elevata resistenza alla trazione, resistenza all’abrasione e capacità di resistere a temperature estreme. L’uretano utilizzato nella produzione di setacci a tensione vibrante è generalmente di alta qualità per garantire prestazioni e longevità ottimali.

Una volta selezionato il materiale uretanico appropriato, viene quindi modellato nella forma desiderata. Ciò si ottiene attraverso un processo noto come colata, in cui l’uretano viene riscaldato fino a diventare liquido, quindi versato in uno stampo che corrisponde alla forma del setaccio. L’uretano viene quindi lasciato raffreddare e indurire, assumendo la forma dello stampo.

La fase successiva del processo di personalizzazione prevede l’applicazione della tensione. Da qui deriva il termine “setaccio tenditore”. Il setaccio in uretano indurito è soggetto a una quantità specifica di tensione, attentamente calibrata per soddisfare i requisiti dell’applicazione specifica a cui è destinato il setaccio. Questo processo di tensionamento è fondamentale in quanto determina le caratteristiche prestazionali del vaglio, comprese la frequenza e l’ampiezza delle vibrazioni.

La fase finale del processo di personalizzazione è l’integrazione del vaglio di tensionamento nel pannello di uretano tensionato con vibratore di fabbrica. Ciò comporta il fissaggio del setaccio sul pannello utilizzando un sistema di montaggio specializzato. Il sistema di montaggio è progettato per consentire una facile sostituzione del setaccio quando necessario, senza interrompere il funzionamento dell’intero pannello.

Il processo di personalizzazione dei setacci a tensione in uretano con scuotitore nei pannelli in uretano a tensione con vibratore di fabbrica è complesso e richiede un livello elevato di precisione e competenza. Tuttavia, i vantaggi di questo processo sono significativi. Personalizzando il vaglio per soddisfare le esigenze specifiche dell’applicazione, i produttori possono ottimizzare le prestazioni dei loro pannelli vibranti, con conseguente miglioramento dell’efficienza e della produttività.

Inoltre, l’uso di materiale uretanico di alta qualità nella produzione dei setacci garantisce la loro durevolezza e longevità, riducendo la necessità di sostituzioni frequenti e diminuendo così i costi di manutenzione. La possibilità di sostituire facilmente il setaccio senza interrompere il funzionamento dell’intero pannello migliora ulteriormente il rapporto costo-efficacia di questi pannelli.

In conclusione, il processo di personalizzazione dei setacci tensionatori in uretano con scuotitore nei pannelli in uretano tensionati con vibratore di fabbrica è una testimonianza dei progressi nella tecnologia di produzione. Mette in mostra la capacità del settore di adattarsi e innovare, creando soluzioni che soddisfano le esigenze specifiche di varie applicazioni migliorando al contempo l’efficienza e riducendo i costi.