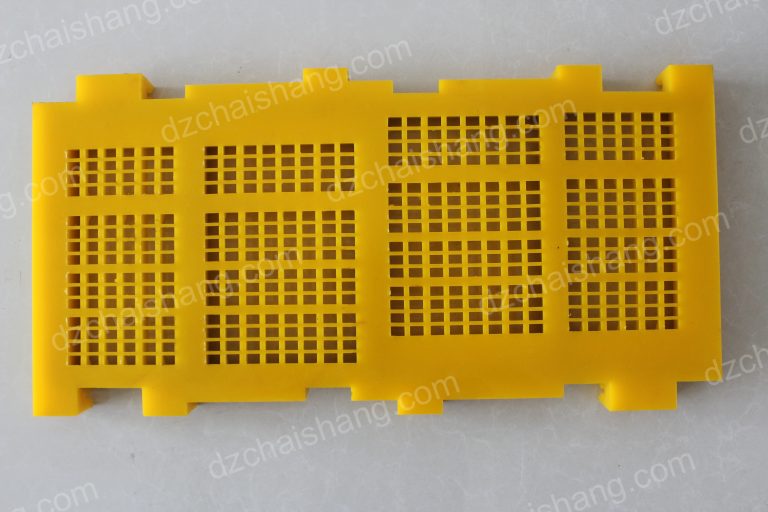

polyurethane shaker screen,polyurethane screen

Benefits of Using polyurethane Shaker screens in Industrial Applications Polyurethane shaker screens have become increasingly popular in industrial applications due to their…

Benefits of Using polyurethane Shaker screens in Industrial Applications

Polyurethane shaker screens have become increasingly popular in industrial applications due to their numerous benefits. These screens are made from polyurethane, a versatile material known for its durability and flexibility. In this article, we will explore the advantages of using polyurethane shaker screens in various industries. One of the key benefits of polyurethane shaker screens is their longevity. Unlike traditional metal screens, polyurethane screens are resistant to corrosion and wear, making them ideal for harsh industrial environments. This durability translates to cost savings for businesses, as they do not need to replace the screens as frequently. Additionally, polyurethane shaker screens are lightweight and easy to handle. This makes them easier to install and remove, reducing downtime and increasing efficiency in industrial processes. The flexibility of polyurethane also allows for easier cleaning and maintenance, further enhancing their usability in industrial settings. Another advantage of polyurethane shaker screens is their superior screening performance. These screens are designed to provide high-quality separation of materials, resulting in more accurate and efficient processing. The flexibility of polyurethane allows for better screening of materials with varying sizes and shapes, ensuring a more consistent end product. Polyurethane shaker screens also offer improved noise reduction compared to metal screens. This is particularly beneficial in industries where noise levels need to be minimized for worker safety and comfort. The dampening properties of polyurethane help to reduce vibrations and noise, creating a quieter working environment. In addition to their durability and performance, polyurethane shaker screens are also environmentally friendly. Polyurethane is a recyclable material, making it a sustainable choice for businesses looking to reduce their environmental impact. By choosing polyurethane screens, companies can contribute to a more sustainable future while still meeting their industrial needs. Overall, the benefits of using polyurethane shaker screens in industrial applications are clear. From their durability and longevity to their superior screening performance and environmental friendliness, polyurethane screens offer a range of advantages for businesses across various industries. By investing in polyurethane shaker screens, companies can improve efficiency, reduce costs, and contribute to a more sustainable future. In conclusion, polyurethane shaker screens are a versatile and effective solution for industrial screening needs. Their durability, performance, and environmental benefits make them a popular choice for businesses looking to improve their processes. With their long-lasting quality and superior screening capabilities, polyurethane screens are a valuable investment for any industrial application.How to Properly Maintain and Clean Polyurethane Screens for Extended Lifespan

Polyurethane screens are a popular choice for many industries due to their durability, flexibility, and resistance to abrasion. However, like any other equipment, polyurethane screens require proper maintenance and cleaning to ensure they have an extended lifespan and continue to perform at their best. In this article, we will discuss some tips on how to properly maintain and clean polyurethane screens. One of the most important aspects of maintaining polyurethane screens is regular inspection. Inspecting the screens on a regular basis allows you to identify any signs of wear and tear, such as tears, holes, or cracks. By catching these issues early, you can prevent them from worsening and potentially causing more significant damage to the screens. In addition to visual inspection, it is also essential to regularly check the tension of the screens. Over time, the tension of the screens can loosen, which can affect their performance. By regularly checking and adjusting the tension of the screens, you can ensure that they are operating at their optimal level. When it comes to cleaning polyurethane screens, it is essential to use the right cleaning products and techniques. Harsh chemicals and abrasive cleaners can damage the screens, so it is best to use mild soap and water for cleaning. Gently scrubbing the screens with a soft brush or cloth can help remove any dirt, debris, or buildup without causing damage.

It is also important to rinse the screens thoroughly after cleaning to remove any soap residue. Leaving soap residue on the screens can attract dirt and debris, which can affect their performance. Once the screens are clean, allow them to dry completely before reinstalling them.

Another important aspect of maintaining polyurethane screens is proper storage. When not in use, store the screens in a cool, dry place away from direct sunlight and extreme temperatures. Storing the screens properly can help prevent them from becoming brittle or deformed, which can affect their performance.

When it comes to cleaning polyurethane screens, it is essential to use the right cleaning products and techniques. Harsh chemicals and abrasive cleaners can damage the screens, so it is best to use mild soap and water for cleaning. Gently scrubbing the screens with a soft brush or cloth can help remove any dirt, debris, or buildup without causing damage.

It is also important to rinse the screens thoroughly after cleaning to remove any soap residue. Leaving soap residue on the screens can attract dirt and debris, which can affect their performance. Once the screens are clean, allow them to dry completely before reinstalling them.

Another important aspect of maintaining polyurethane screens is proper storage. When not in use, store the screens in a cool, dry place away from direct sunlight and extreme temperatures. Storing the screens properly can help prevent them from becoming brittle or deformed, which can affect their performance.In addition to regular maintenance and cleaning, it is also essential to handle polyurethane screens with care. Avoid dropping or mishandling the screens, as this can cause damage. When installing or removing the screens, be gentle and take your time to ensure they are properly positioned. By following these tips on how to properly maintain and clean polyurethane screens, you can help extend their lifespan and ensure they continue to perform at their best. Regular inspection, proper cleaning techniques, and careful handling are key to keeping polyurethane screens in top condition. With proper maintenance, polyurethane screens can provide reliable performance for years to come.