vibrating high frequency PU mesh Producer,direct trade tension Rubber panel

Exploring the Production Process of high frequency Vibrating PU mesh and Direct Trade Tension Rubber Panel The production process of high frequency…

Exploring the Production Process of high frequency Vibrating PU mesh and Direct Trade Tension Rubber Panel

The production process of high frequency vibrating PU (polyurethane) mesh and direct trade tension rubber panel is a fascinating journey that combines advanced technology, meticulous craftsmanship, and a deep understanding of material science. As a leading producer in this industry, we are committed to delivering products of the highest quality, ensuring that they meet the stringent demands of various sectors, including mining, construction, and recycling. The production of high frequency vibrating PU mesh begins with the selection of premium polyurethane, a material known for its exceptional durability, flexibility, and resistance to abrasion, corrosion, and temperature variations. The polyurethane is then heated to a specific temperature, allowing it to be molded into the desired shape. This process, known as thermoforming, is carried out under strict quality control measures to ensure the consistency and precision of the final product. Once the polyurethane has been molded, it is then subjected to a high frequency vibration process. This is a critical step in the production process as it helps to enhance the strength and durability of the mesh, making it capable of withstanding high levels of tension and stress. The high frequency vibration also ensures that the mesh has a uniform and consistent structure, which is essential for its performance and efficiency. The production of direct trade tension rubber panel, on the other hand, involves a different set of processes. The first step is the selection of high-quality rubber, which is known for its elasticity, resilience, and resistance to wear and tear. The rubber is then mixed with various additives to enhance its properties and performance.

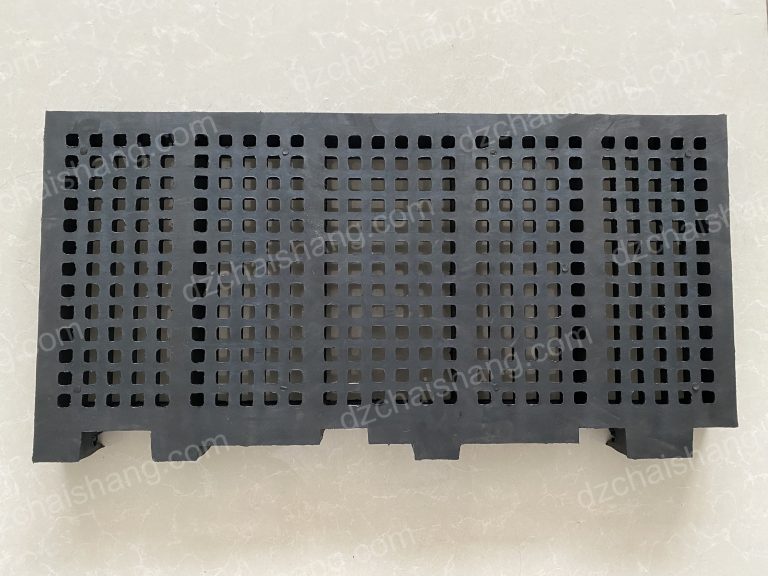

The rubber mixture is then poured into a mold and subjected to high pressure and temperature. This process, known as vulcanization, transforms the rubber from a soft and pliable material into a strong and durable one. The vulcanized rubber is then cut into panels of specific dimensions, ensuring that they meet the exact requirements of our clients.

The final step in the production process is the application of tension to the rubber panels. This is done using specialized equipment that applies a precise amount of force to the panels, stretching them to their optimal tension. This process not only enhances the strength and durability of the panels but also ensures that they have a uniform and consistent structure.

The production of direct trade tension rubber panel, on the other hand, involves a different set of processes. The first step is the selection of high-quality rubber, which is known for its elasticity, resilience, and resistance to wear and tear. The rubber is then mixed with various additives to enhance its properties and performance.

The rubber mixture is then poured into a mold and subjected to high pressure and temperature. This process, known as vulcanization, transforms the rubber from a soft and pliable material into a strong and durable one. The vulcanized rubber is then cut into panels of specific dimensions, ensuring that they meet the exact requirements of our clients.

The final step in the production process is the application of tension to the rubber panels. This is done using specialized equipment that applies a precise amount of force to the panels, stretching them to their optimal tension. This process not only enhances the strength and durability of the panels but also ensures that they have a uniform and consistent structure.