Polyurethane sheet, polyurethane board,China Manufacturer

Exploring the Versatility of polyurethane Sheets: Insights from China’s Leading Manufacturers Polyurethane, a versatile and resilient material, has found its way into…

Exploring the Versatility of polyurethane Sheets: Insights from China’s Leading Manufacturers

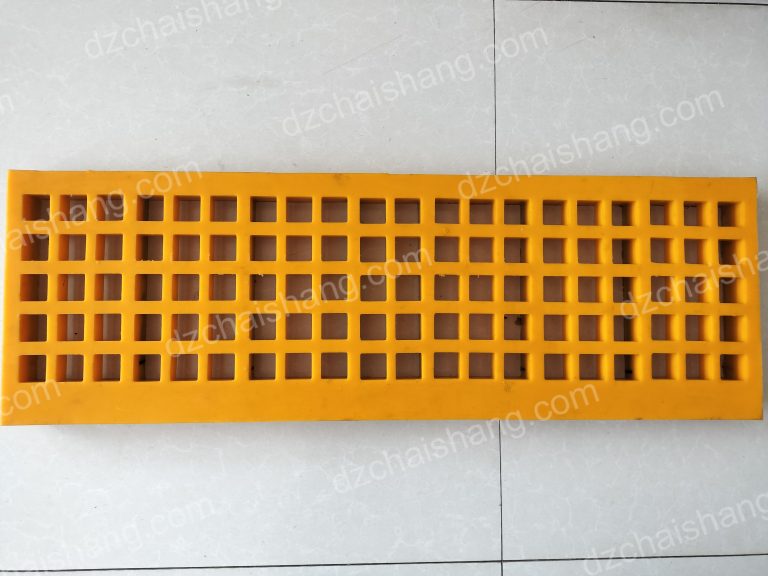

Polyurethane, a versatile and resilient material, has found its way into a myriad of applications in various industries. From automotive parts to furniture, polyurethane’s unique properties make it a preferred choice for manufacturers worldwide. As a leading manufacturer of polyurethane sheets and boards in China, we have a deep understanding of this material’s potential and its wide-ranging applications. Polyurethane sheets, also known as PU sheets, are renowned for their durability and resistance to wear, tear, and environmental factors. These sheets are made by casting liquid polyurethane into a mold, which is then allowed to cure. The result is a material that is not only tough but also flexible, making it ideal for use in a variety of applications. Polyurethane sheets can be easily cut, shaped, and molded, allowing manufacturers to create custom parts and products with ease. One of the key advantages of polyurethane sheets is their resistance to abrasion. This makes them particularly useful in industries where materials are subject to high levels of wear and tear, such as mining, construction, and manufacturing. Polyurethane sheets can withstand the rigors of these environments, providing a long-lasting solution that can help to reduce maintenance costs and downtime. In addition to their durability, polyurethane sheets also offer excellent resistance to oils, greases, and many chemicals. This makes them an ideal choice for use in the automotive industry, where they can be used to create gaskets, seals, and other parts that need to withstand harsh conditions. Furthermore, their resistance to UV radiation makes them suitable for outdoor applications, where they can provide a durable and long-lasting solution. Polyurethane boards, on the other hand, are typically used in applications that require a higher level of rigidity. These boards are made by injecting liquid polyurethane into a mold under high pressure, resulting in a material that is denser and more rigid than polyurethane sheets. This makes them ideal for use in applications that require a high level of structural strength, such as in the construction of buildings and bridges. Despite their rigidity, polyurethane boards still retain the flexibility that is characteristic of polyurethane. This means that they can be easily cut and shaped, allowing for a high degree of customization. Furthermore, their resistance to environmental factors means that they can provide a durable and long-lasting solution in a wide range of applications.

In conclusion, polyurethane sheets and boards offer a versatile and durable solution for a wide range of applications. Their unique properties, including their resistance to wear, tear, and environmental factors, make them a preferred choice for manufacturers in various industries. As a leading manufacturer of polyurethane sheets and boards in China, we are committed to providing high-quality products that meet the diverse needs of our customers. Whether you need a flexible and durable material for your manufacturing process or a rigid and strong material for your construction project, polyurethane offers a solution that can meet your needs.

Despite their rigidity, polyurethane boards still retain the flexibility that is characteristic of polyurethane. This means that they can be easily cut and shaped, allowing for a high degree of customization. Furthermore, their resistance to environmental factors means that they can provide a durable and long-lasting solution in a wide range of applications.

In conclusion, polyurethane sheets and boards offer a versatile and durable solution for a wide range of applications. Their unique properties, including their resistance to wear, tear, and environmental factors, make them a preferred choice for manufacturers in various industries. As a leading manufacturer of polyurethane sheets and boards in China, we are committed to providing high-quality products that meet the diverse needs of our customers. Whether you need a flexible and durable material for your manufacturing process or a rigid and strong material for your construction project, polyurethane offers a solution that can meet your needs.