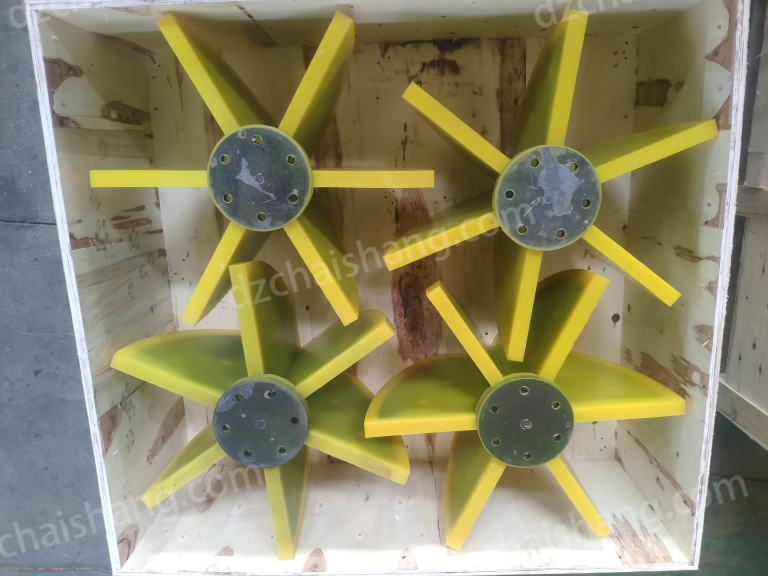

Polyurethane Screen Sieve Panels Plate ,polyurethane Mining Vibrating Screen Mesh

Exploring the Efficiency of polyurethane screen sieve Panels Plate in mining vibrating screen mesh Polyurethane SCREEN SIEVE Panels Plate, commonly known as…

Exploring the Efficiency of polyurethane screen sieve Panels Plate in mining vibrating screen mesh

Polyurethane SCREEN SIEVE Panels Plate, commonly known as polyurethane mining VIBRATING screen mesh, has emerged as a revolutionary solution in the mining industry. This innovative product has significantly enhanced the efficiency and productivity of mining operations, making it an indispensable tool in the sector. Polyurethane, a versatile and resilient material, is the primary component of these screen sieve panels. It is renowned for its exceptional durability, resistance to abrasion, and ability to withstand extreme conditions. These attributes make it an ideal choice for mining applications, where equipment is often subjected to harsh environments and rigorous use. Moreover, the polyurethane mining vibrating screen mesh is also known for its noise reduction capabilities. The material’s inherent sound-absorbing properties help to minimize noise levels during operation, contributing to a safer and more comfortable working environment. This is particularly beneficial in mining settings, where noise pollution can be a significant concern.

The durability of the Polyurethane Screen Sieve Panels Plate is another factor that contributes to its efficiency. Unlike traditional metal screens, which are prone to wear and tear, polyurethane screens are highly resistant to corrosion and abrasion. This means they can maintain their performance over a longer period, reducing the need for frequent replacements and maintenance.

Furthermore, the flexibility of polyurethane allows the screen panels to be customized to suit specific mining needs. They can be manufactured in various sizes, shapes, and configurations, providing a tailored solution for each mining operation. This adaptability not only enhances the effectiveness of the screening process but also improves the overall productivity of mining operations.

The use of Polyurethane Screen Sieve Panels Plate in mining vibrating screen mesh also has environmental benefits. The durability and longevity of these panels mean fewer replacements are needed, resulting in less waste. Additionally, the high screening efficiency reduces the amount of unprocessed material, minimizing the environmental impact of mining operations.

In conclusion, the Polyurethane Screen Sieve Panels Plate has proven to be a game-changer in the mining industry. Its superior durability, high screening efficiency, noise reduction capabilities, and adaptability make it an ideal solution for mining vibrating screen mesh. By leveraging the benefits of this innovative tool, mining companies can enhance their operations’ efficiency and productivity, while also minimizing their environmental footprint.

Moreover, the polyurethane mining vibrating screen mesh is also known for its noise reduction capabilities. The material’s inherent sound-absorbing properties help to minimize noise levels during operation, contributing to a safer and more comfortable working environment. This is particularly beneficial in mining settings, where noise pollution can be a significant concern.

The durability of the Polyurethane Screen Sieve Panels Plate is another factor that contributes to its efficiency. Unlike traditional metal screens, which are prone to wear and tear, polyurethane screens are highly resistant to corrosion and abrasion. This means they can maintain their performance over a longer period, reducing the need for frequent replacements and maintenance.

Furthermore, the flexibility of polyurethane allows the screen panels to be customized to suit specific mining needs. They can be manufactured in various sizes, shapes, and configurations, providing a tailored solution for each mining operation. This adaptability not only enhances the effectiveness of the screening process but also improves the overall productivity of mining operations.

The use of Polyurethane Screen Sieve Panels Plate in mining vibrating screen mesh also has environmental benefits. The durability and longevity of these panels mean fewer replacements are needed, resulting in less waste. Additionally, the high screening efficiency reduces the amount of unprocessed material, minimizing the environmental impact of mining operations.

In conclusion, the Polyurethane Screen Sieve Panels Plate has proven to be a game-changer in the mining industry. Its superior durability, high screening efficiency, noise reduction capabilities, and adaptability make it an ideal solution for mining vibrating screen mesh. By leveraging the benefits of this innovative tool, mining companies can enhance their operations’ efficiency and productivity, while also minimizing their environmental footprint.