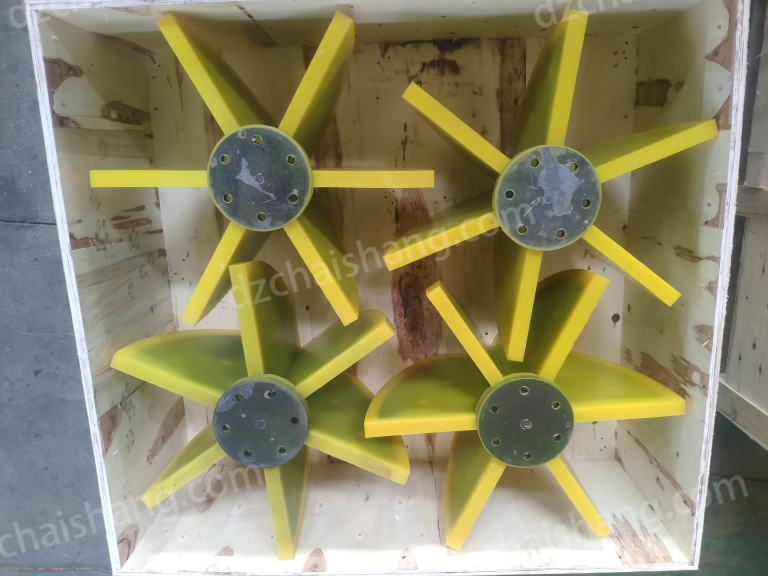

Polyurethane Screen Sieve Panels Plate,polyurethane Mining Vibrating Screen Mesh

Exploring the Efficiency of polyurethane screen sieve Panels Plate in mining vibrating screen mesh Polyurethane SCREEN SIEVE Panels Plate, commonly known as…

Exploring the Efficiency of polyurethane screen sieve Panels Plate in mining vibrating screen mesh

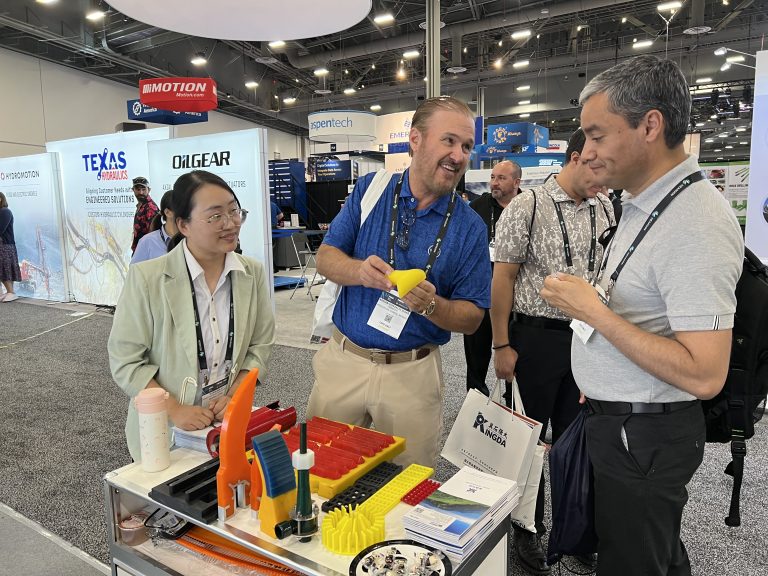

Polyurethane SCREEN SIEVE Panels Plate, commonly known as polyurethane mining VIBRATING screen mesh, has revolutionized the mining industry with its superior efficiency and durability. This innovative technology, which has been a game-changer in the mining sector, is designed to optimize the screening process, thereby enhancing productivity and profitability. Polyurethane, a versatile material with exceptional properties, is the key component of these screen sieve panels. It is renowned for its high resistance to abrasion, wear, and tear, making it an ideal choice for the harsh conditions of the mining environment. The resilience of polyurethane ensures that the screen sieve panels can withstand the constant impact and vibration associated with the screening process, thereby reducing the need for frequent replacements and maintenance. The design of the polyurethane screen sieve panels plate is another factor contributing to its efficiency. The panels are designed with precision to ensure maximum screening performance. The apertures or holes in the panels are strategically placed to facilitate the effective separation of materials. This meticulous design allows for the accurate classification of materials, which is crucial in the mining process. The panels also have a self-cleaning mechanism, which prevents the clogging of the screen, thereby maintaining the efficiency of the screening process. The polyurethane mining vibrating screen mesh also offers flexibility in terms of its application. It can be used in a variety of mining operations, including coal, gold, iron ore, and copper mining. This versatility makes it a cost-effective solution for mining companies, as they can use the same screen sieve panels across different operations. In conclusion, the polyurethane screen sieve panels plate, or polyurethane mining vibrating screen mesh, is a testament to the power of innovation in the mining industry. Its superior efficiency, durability, versatility, and contribution to safety and environmental sustainability make it an invaluable tool in the mining process. As the mining industry continues to evolve, it is likely that the use of polyurethane screen sieve panels will become even more widespread, further enhancing the efficiency and profitability of mining operations.

In conclusion, the polyurethane screen sieve panels plate, or polyurethane mining vibrating screen mesh, is a testament to the power of innovation in the mining industry. Its superior efficiency, durability, versatility, and contribution to safety and environmental sustainability make it an invaluable tool in the mining process. As the mining industry continues to evolve, it is likely that the use of polyurethane screen sieve panels will become even more widespread, further enhancing the efficiency and profitability of mining operations.