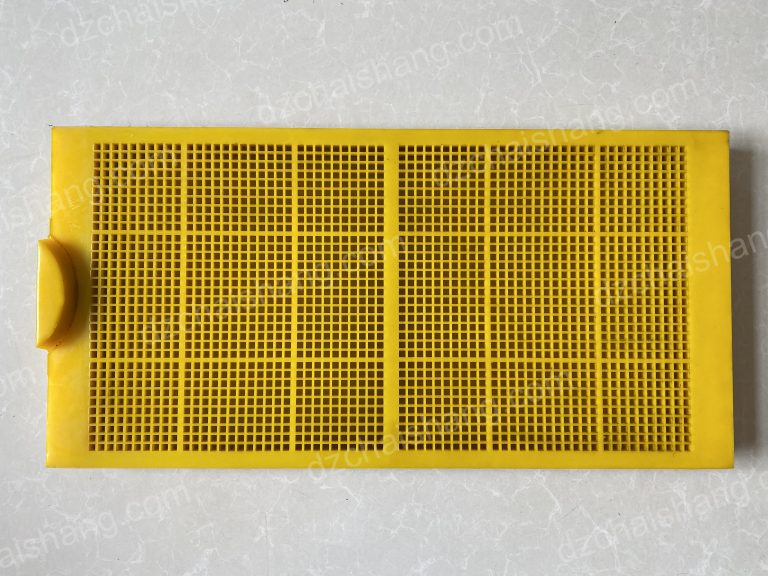

Polyurethane Mesh for dewatering,mining screen mesh

Advantages of polyurethane mesh in Dewatering Applications Polyurethane mesh has become increasingly popular in dewatering applications due to its numerous advantages over…

Advantages of polyurethane mesh in Dewatering Applications

Polyurethane mesh has become increasingly popular in dewatering applications due to its numerous advantages over traditional metal mesh. In the mining industry, dewatering is a crucial process that involves removing water from solid materials or soil in order to separate the valuable minerals from the waste material. Polyurethane mesh offers several key benefits that make it an ideal choice for dewatering applications. One of the main advantages of polyurethane mesh is its durability. Unlike metal mesh, which can corrode and degrade over time, polyurethane mesh is resistant to corrosion and wear, making it a long-lasting solution for dewatering applications. This durability ensures that the mesh can withstand the harsh conditions often found in mining operations, such as high temperatures, abrasive materials, and heavy loads.

In addition to its durability, polyurethane mesh is also highly flexible and can be easily molded to fit a variety of shapes and sizes. This flexibility allows for greater customization and precision in dewatering applications, ensuring that the mesh can effectively separate solids from liquids with minimal waste. Polyurethane mesh can also be easily installed and replaced, reducing downtime and maintenance costs for mining operations.

Another key advantage of polyurethane mesh is its high screening efficiency. The open design of the mesh allows for efficient drainage and dewatering of materials, resulting in faster processing times and higher productivity. This increased efficiency can lead to cost savings for mining operations by reducing energy consumption and improving overall process performance.

Polyurethane mesh is also lightweight and easy to handle, making it a practical choice for dewatering applications. Its lightweight design reduces the strain on equipment and personnel, making it easier to transport and install in remote or challenging locations. This ease of handling can help to improve safety and efficiency in mining operations, reducing the risk of accidents and injuries.

Furthermore, polyurethane mesh is environmentally friendly and sustainable. Unlike metal mesh, which can release harmful chemicals and pollutants into the environment, polyurethane mesh is non-toxic and recyclable. This makes it a more sustainable option for dewatering applications, helping to reduce the environmental impact of mining operations and promote responsible resource management.

Overall, polyurethane mesh offers a range of advantages that make it an ideal choice for dewatering applications in the mining industry. Its durability, flexibility, efficiency, and sustainability make it a cost-effective and practical solution for separating solids from liquids in a variety of mining operations. By choosing polyurethane mesh for dewatering applications, mining companies can improve their process performance, reduce maintenance costs, and minimize their environmental footprint.

One of the main advantages of polyurethane mesh is its durability. Unlike metal mesh, which can corrode and degrade over time, polyurethane mesh is resistant to corrosion and wear, making it a long-lasting solution for dewatering applications. This durability ensures that the mesh can withstand the harsh conditions often found in mining operations, such as high temperatures, abrasive materials, and heavy loads.

In addition to its durability, polyurethane mesh is also highly flexible and can be easily molded to fit a variety of shapes and sizes. This flexibility allows for greater customization and precision in dewatering applications, ensuring that the mesh can effectively separate solids from liquids with minimal waste. Polyurethane mesh can also be easily installed and replaced, reducing downtime and maintenance costs for mining operations.

Another key advantage of polyurethane mesh is its high screening efficiency. The open design of the mesh allows for efficient drainage and dewatering of materials, resulting in faster processing times and higher productivity. This increased efficiency can lead to cost savings for mining operations by reducing energy consumption and improving overall process performance.

Polyurethane mesh is also lightweight and easy to handle, making it a practical choice for dewatering applications. Its lightweight design reduces the strain on equipment and personnel, making it easier to transport and install in remote or challenging locations. This ease of handling can help to improve safety and efficiency in mining operations, reducing the risk of accidents and injuries.

Furthermore, polyurethane mesh is environmentally friendly and sustainable. Unlike metal mesh, which can release harmful chemicals and pollutants into the environment, polyurethane mesh is non-toxic and recyclable. This makes it a more sustainable option for dewatering applications, helping to reduce the environmental impact of mining operations and promote responsible resource management.

Overall, polyurethane mesh offers a range of advantages that make it an ideal choice for dewatering applications in the mining industry. Its durability, flexibility, efficiency, and sustainability make it a cost-effective and practical solution for separating solids from liquids in a variety of mining operations. By choosing polyurethane mesh for dewatering applications, mining companies can improve their process performance, reduce maintenance costs, and minimize their environmental footprint.

Comparing Polyurethane Mesh and Traditional mining screen mesh

Polyurethane mesh has become increasingly popular in the mining industry for dewatering and screening applications. This innovative material offers a number of advantages over traditional mining screen mesh, making it a preferred choice for many mining operations. One of the key benefits of polyurethane mesh is its durability. Unlike traditional metal mesh, polyurethane mesh is resistant to corrosion and wear, making it ideal for use in harsh mining environments. This durability ensures that the mesh will last longer and require less frequent replacement, ultimately saving time and money for mining companies. In addition to its durability, polyurethane mesh also offers superior performance in dewatering applications. The open design of the mesh allows for efficient drainage of water, making it ideal for use in dewatering screens. This can help to improve the efficiency of the dewatering process, resulting in faster processing times and increased productivity for mining operations. Another advantage of polyurethane mesh is its flexibility. Traditional metal mesh is rigid and can be difficult to work with, especially when it comes to customizing screens for specific applications. Polyurethane mesh, on the other hand, is flexible and can be easily molded to fit a variety of screen sizes and shapes. This flexibility makes it easier to create custom screens that meet the specific needs of a mining operation.Polyurethane mesh is also lightweight, making it easier to handle and install than traditional metal mesh. This can help to reduce labor costs and improve overall efficiency in the screening process. Additionally, the lightweight nature of polyurethane mesh can help to reduce the overall weight of screening equipment, making it easier to transport and set up on site. Despite these advantages, there are some limitations to polyurethane mesh that should be considered. For example, polyurethane mesh may not be as strong as traditional metal mesh, making it less suitable for heavy-duty screening applications. Additionally, polyurethane mesh may be more prone to damage from sharp objects or abrasive materials, so care must be taken to ensure that the mesh is properly maintained and replaced as needed. In conclusion, polyurethane mesh offers a number of advantages over traditional mining screen mesh, including durability, performance, flexibility, and lightweight design. While there are some limitations to consider, the benefits of polyurethane mesh make it a preferred choice for many mining operations. By choosing polyurethane mesh for dewatering and screening applications, mining companies can improve efficiency, reduce costs, and ultimately increase productivity.