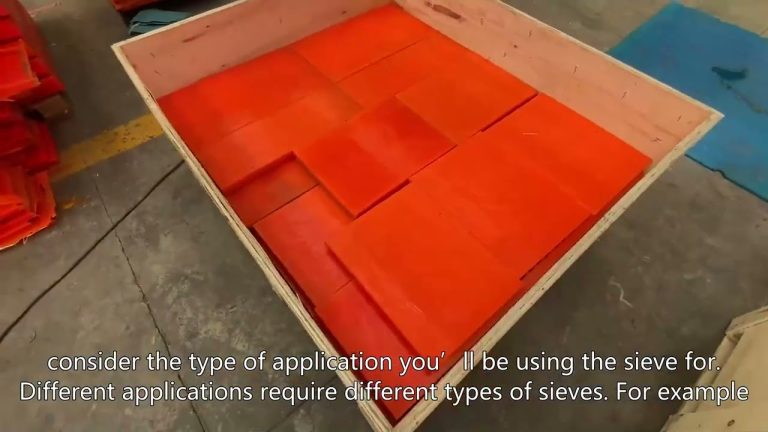

New vibrating screen,Polyurethane panel

Benefits of Using a New vibrating screen in Industrial Applications

In the world of industrial applications, efficiency and productivity are key factors in ensuring success. One important piece of equipment that plays a crucial role in many industries is the vibrating screen. Vibrating screens are used to separate materials based on size and shape, making them essential in processes such as sorting, grading, and dewatering. Recently, a new type of vibrating screen has been introduced to the market that offers several benefits over traditional screens: the polyurethane panel vibrating screen. Polyurethane Panels are a type of synthetic material that is known for its durability, flexibility, and resistance to abrasion. These qualities make polyurethane panels an ideal choice for vibrating screens, as they can withstand the high frequency and amplitude of the vibrations without wearing out quickly. This means that polyurethane panel vibrating screens have a longer lifespan compared to screens made from other materials, reducing the need for frequent replacements and maintenance. Another benefit of using a polyurethane panel vibrating screen is its ability to provide a higher screening efficiency. The flexibility of the polyurethane panels allows for more effective screening of materials, resulting in a cleaner separation of particles. This leads to a higher quality end product and increased productivity for industrial processes. Additionally, the open area design of polyurethane panels allows for better drainage and dewatering of materials, making them ideal for applications where moisture control is important. Polyurethane panel vibrating screens also offer improved wear resistance compared to traditional screens. The abrasion-resistant properties of polyurethane panels make them less prone to damage from abrasive materials, reducing the risk of downtime and maintenance costs. This durability ensures that the vibrating screen can continue to operate efficiently even in harsh working conditions, providing a reliable solution for industrial applications. Furthermore, polyurethane panel vibrating screens are lightweight and easy to install, making them a cost-effective option for businesses looking to upgrade their screening equipment. The lightweight design of polyurethane panels reduces the overall weight of the vibrating screen, making it easier to transport and handle during installation. This can result in lower installation costs and faster setup times, allowing businesses to quickly integrate the new vibrating screen into their operations. In conclusion, the introduction of polyurethane panel vibrating screens has brought several benefits to industrial applications. From increased durability and screening efficiency to improved wear resistance and ease of installation, polyurethane panels offer a superior solution for businesses looking to enhance their screening processes. By investing in a polyurethane panel vibrating screen, businesses can improve their productivity, reduce maintenance costs, and achieve higher quality end products. With these advantages in mind, it is clear that polyurethane panel vibrating screens are a valuable asset for industries seeking to optimize their screening operations.How Polyurethane Panels Improve Efficiency and Longevity of Vibrating Screens

Vibrating screens are essential equipment in various industries, including mining, construction, and agriculture. They are used to separate materials based on size, shape, and composition. The efficiency and longevity of vibrating screens are crucial for the smooth operation of these industries. One way to improve the performance of vibrating screens is by using polyurethane panels. Polyurethane panels are a popular choice for vibrating screens due to their durability, flexibility, and efficiency. These panels are made from polyurethane, a synthetic material known for its strength and resilience. Polyurethane panels are designed to withstand the harsh conditions of vibrating screens, including high vibration, abrasion, and impact. One of the key benefits of polyurethane panels is their longevity. Unlike traditional steel or rubber panels, polyurethane panels are more resistant to wear and tear. This means that they can last longer without needing to be replaced, saving time and money for businesses. Additionally, polyurethane panels are easy to install and maintain, further reducing downtime and increasing productivity.

Another advantage of polyurethane panels is their efficiency. These panels are designed to maximize screening efficiency by providing a smooth surface for materials to pass through. This results in higher throughput and better separation of materials, leading to improved overall performance of vibrating screens. Polyurethane panels also reduce blinding and pegging, common issues that can affect the efficiency of vibrating screens.

Polyurethane panels are also more environmentally friendly than traditional steel or rubber panels. Polyurethane is a recyclable material, which means that it can be reused or repurposed at the end of its life cycle. This helps reduce waste and minimize the environmental impact of vibrating screens. Additionally, polyurethane panels are non-toxic and safe for workers, making them a sustainable choice for businesses.

In conclusion, polyurethane panels are an excellent choice for improving the efficiency and longevity of vibrating screens. These panels are durable, flexible, and efficient, making them ideal for a wide range of industries. By using polyurethane panels, businesses can increase productivity, reduce downtime, and minimize environmental impact. Overall, polyurethane panels are a cost-effective and sustainable solution for enhancing the performance of vibrating screens.

One of the key benefits of polyurethane panels is their longevity. Unlike traditional steel or rubber panels, polyurethane panels are more resistant to wear and tear. This means that they can last longer without needing to be replaced, saving time and money for businesses. Additionally, polyurethane panels are easy to install and maintain, further reducing downtime and increasing productivity.

Another advantage of polyurethane panels is their efficiency. These panels are designed to maximize screening efficiency by providing a smooth surface for materials to pass through. This results in higher throughput and better separation of materials, leading to improved overall performance of vibrating screens. Polyurethane panels also reduce blinding and pegging, common issues that can affect the efficiency of vibrating screens.

Polyurethane panels are also more environmentally friendly than traditional steel or rubber panels. Polyurethane is a recyclable material, which means that it can be reused or repurposed at the end of its life cycle. This helps reduce waste and minimize the environmental impact of vibrating screens. Additionally, polyurethane panels are non-toxic and safe for workers, making them a sustainable choice for businesses.

In conclusion, polyurethane panels are an excellent choice for improving the efficiency and longevity of vibrating screens. These panels are durable, flexible, and efficient, making them ideal for a wide range of industries. By using polyurethane panels, businesses can increase productivity, reduce downtime, and minimize environmental impact. Overall, polyurethane panels are a cost-effective and sustainable solution for enhancing the performance of vibrating screens.

Comparison of Different Types of Polyurethane Panels for Vibrating Screens

Polyurethane panels are a popular choice for vibrating screens due to their durability, flexibility, and resistance to abrasion. They are used in a variety of industries, including mining, construction, and recycling, to separate materials based on size. With advancements in technology, new types of polyurethane panels are constantly being developed to improve efficiency and performance. One of the latest innovations in vibrating screen polyurethane panels is the introduction of the new vibrating screen polyurethane panel. This panel is designed to provide better screening efficiency and longer wear life compared to traditional polyurethane panels. It is made from high-quality polyurethane material that is resistant to wear and tear, making it ideal for heavy-duty applications. The new vibrating screen polyurethane panel offers several advantages over other types of polyurethane panels. One of the key benefits is its improved screening efficiency. The panel is designed with a unique pattern that allows for better material flow and increased screening capacity. This results in higher throughput and reduced downtime, leading to improved productivity and cost savings for businesses. In addition to improved screening efficiency, the new vibrating screen polyurethane panel also offers longer wear life. The high-quality polyurethane material used in the panel is highly resistant to abrasion, ensuring that it can withstand the rigors of continuous use in demanding applications. This means that businesses can expect reduced maintenance costs and longer service life from the panel, ultimately leading to increased profitability.Another advantage of the new vibrating screen polyurethane panel is its versatility. The panel is available in a variety of sizes and configurations to suit different screening requirements. Whether businesses are looking to separate fine particles or large aggregates, there is a panel option that can meet their specific needs. This flexibility makes the panel a versatile solution for a wide range of applications. When comparing the new vibrating screen polyurethane panel to other types of polyurethane panels, it is clear that it offers superior performance and durability. Traditional polyurethane panels may wear out quickly or become damaged under heavy loads, leading to increased maintenance costs and downtime. In contrast, the new vibrating screen polyurethane panel is designed to withstand the toughest conditions and provide long-lasting performance. Overall, the new vibrating screen polyurethane panel is a game-changer in the world of vibrating screens. Its improved screening efficiency, longer wear life, and versatility make it a top choice for businesses looking to optimize their screening operations. With this innovative panel, businesses can expect increased productivity, reduced maintenance costs, and improved profitability. As technology continues to advance, it is exciting to see how new developments like the vibrating screen polyurethane panel will continue to revolutionize the industry.