Introduction to polyurethane high frequency screen for coal mines

Benefits of Using polyurethane high frequency screens in Coal Mines Polyurethane high frequency screens have become increasingly popular in coal mines due…

Benefits of Using polyurethane high frequency screens in Coal Mines

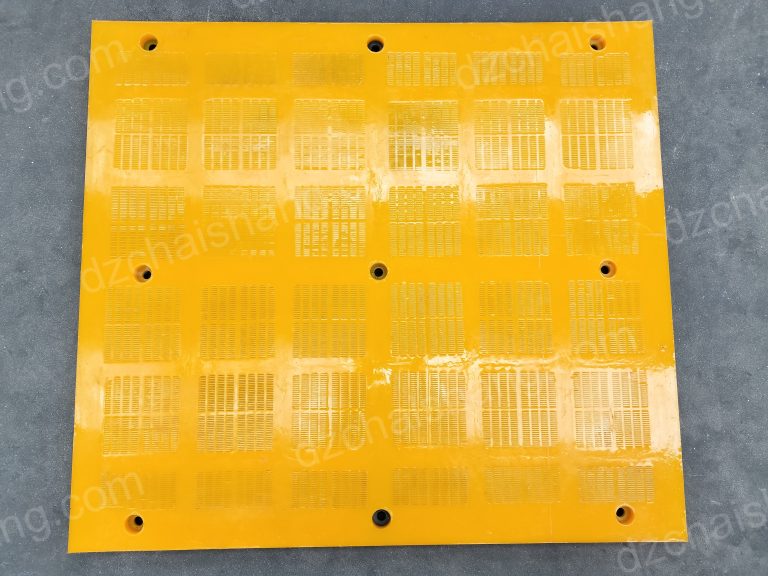

Polyurethane high frequency screens have become increasingly popular in coal mines due to their numerous benefits. These screens are made from a durable and flexible material that offers many advantages over traditional steel screens. In this article, we will explore the benefits of using polyurethane high frequency screens in coal mines. One of the main advantages of polyurethane high frequency screens is their durability. These screens are resistant to abrasion, corrosion, and impact, making them ideal for the harsh conditions found in coal mines. Unlike steel screens, polyurethane screens do not rust or corrode, which helps to extend their lifespan and reduce maintenance costs. In addition to their durability, polyurethane high frequency screens are also highly flexible. This flexibility allows the screens to absorb impact and reduce the risk of damage from rocks and other materials passing through the screen. This can help to prevent downtime and increase productivity in coal mines. Another benefit of polyurethane high frequency screens is their high screening efficiency. These screens are designed to provide a high open area, which allows for more material to pass through the screen quickly and efficiently. This can help to increase the overall throughput of the screening process and improve the quality of the final product.How to Properly Maintain and Extend the Lifespan of Polyurethane High Frequency Screens in Coal Mines

Polyurethane high frequency screens have become a popular choice for coal mines due to their durability and efficiency in separating materials. These screens are designed to withstand the harsh conditions of coal mining operations, making them a reliable option for companies looking to improve their screening processes. However, like any equipment, proper maintenance is essential to ensure the longevity of polyurethane high frequency screens. One of the key factors in maintaining polyurethane high frequency screens is regular cleaning. Coal mines are notorious for producing a significant amount of dust and debris, which can quickly build up on the screens and impact their performance. To prevent this buildup, it is important to clean the screens regularly using a mild detergent and water. Avoid using harsh chemicals or abrasive materials, as these can damage the polyurethane material. In addition to cleaning, it is also important to inspect the screens regularly for any signs of wear or damage. Polyurethane screens are designed to be durable, but they can still be susceptible to tears or punctures if not properly maintained. Inspecting the screens for any issues and addressing them promptly can help prevent more significant damage and extend the lifespan of the screens. Another important aspect of maintaining polyurethane high frequency screens is proper storage when not in use. Storing the screens in a clean, dry environment away from direct sunlight can help prevent degradation of the polyurethane material. Additionally, storing the screens in a way that prevents them from being bent or crushed can help maintain their shape and integrity. When it comes to installation and operation, following the manufacturer’s guidelines is crucial for ensuring the screens perform optimally. Improper installation or operation can lead to premature wear and damage, reducing the lifespan of the screens. It is important to follow the recommended procedures for installing and operating polyurethane high frequency screens to maximize their efficiency and longevity.

Regularly monitoring the performance of the screens can also help identify any issues early on and prevent more significant problems down the line. Keeping track of factors such as throughput, screen efficiency, and wear patterns can provide valuable insights into the condition of the screens and help determine when maintenance or replacement may be necessary.

In conclusion, proper maintenance is essential for extending the lifespan of polyurethane high frequency screens in coal mines. Regular cleaning, inspection, and storage, along with following manufacturer guidelines for installation and operation, can help ensure the screens perform optimally and last longer. By taking care of these screens, coal mines can improve their screening processes and reduce downtime and maintenance costs in the long run.

When it comes to installation and operation, following the manufacturer’s guidelines is crucial for ensuring the screens perform optimally. Improper installation or operation can lead to premature wear and damage, reducing the lifespan of the screens. It is important to follow the recommended procedures for installing and operating polyurethane high frequency screens to maximize their efficiency and longevity.

Regularly monitoring the performance of the screens can also help identify any issues early on and prevent more significant problems down the line. Keeping track of factors such as throughput, screen efficiency, and wear patterns can provide valuable insights into the condition of the screens and help determine when maintenance or replacement may be necessary.

In conclusion, proper maintenance is essential for extending the lifespan of polyurethane high frequency screens in coal mines. Regular cleaning, inspection, and storage, along with following manufacturer guidelines for installation and operation, can help ensure the screens perform optimally and last longer. By taking care of these screens, coal mines can improve their screening processes and reduce downtime and maintenance costs in the long run.