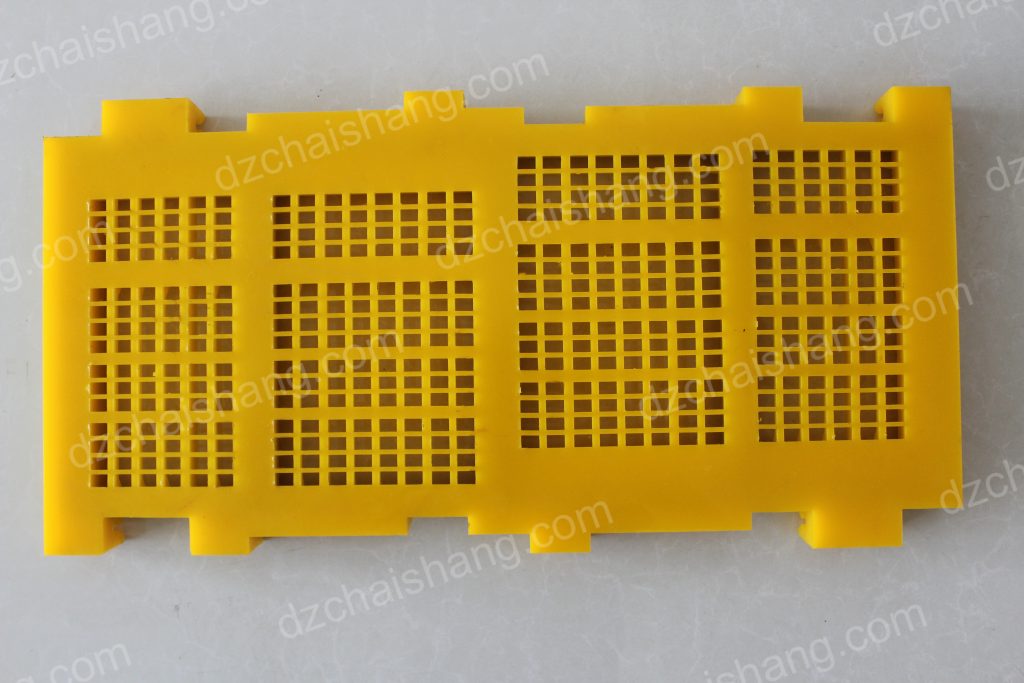

Good quality shaker circular vibrating Polyurethane plate

Benefits of Using Good Quality Shaker Circular Vibrating polyurethane Plate polyurethane plates are a popular choice for shaker screens due to their…

Benefits of Using Good Quality Shaker Circular Vibrating polyurethane Plate

polyurethane plates are a popular choice for shaker screens due to their durability, flexibility, and resistance to abrasion. When it comes to shaker circular vibrating screens, having a good quality polyurethane plate can make all the difference in the efficiency and effectiveness of the screening process.

One of the key benefits of using a good quality shaker circular vibrating polyurethane plate is its ability to withstand high levels of vibration without losing its shape or integrity. This is crucial in ensuring that the screen operates smoothly and efficiently, without any disruptions or malfunctions. The flexibility of polyurethane also allows for better screening performance, as it can adapt to the varying sizes and shapes of the materials being processed.

In addition to its durability and flexibility, a good quality polyurethane plate is also highly resistant to abrasion. This means that it can withstand the wear and tear of constant use, without deteriorating or needing frequent replacements. This not only saves time and money on maintenance costs, but also ensures that the screening process remains consistent and reliable over time.

Another benefit of using a good quality shaker circular vibrating polyurethane plate is its ability to reduce noise levels during operation. The soft and flexible nature of polyurethane helps to dampen vibrations and minimize the noise produced by the screen, creating a more comfortable working environment for operators and reducing noise pollution in the surrounding area.

Furthermore, polyurethane plates are easy to install and replace, making maintenance and repairs quick and hassle-free. This means less downtime for the screening equipment, allowing for continuous operation and increased productivity. The ease of installation also means that operators can quickly switch out worn or damaged plates, ensuring that the screen remains in optimal condition at all times.

In terms of performance, a good quality shaker circular vibrating polyurethane plate offers superior screening efficiency and accuracy. The smooth surface of the polyurethane material allows for efficient material flow and separation, resulting in a higher quality end product. This is essential for industries such as mining, construction, and recycling, where the accuracy of screening results can have a significant impact on overall production and profitability.

Overall, the benefits of using a good quality shaker circular vibrating polyurethane plate are clear. From its durability and flexibility to its resistance to abrasion and noise reduction capabilities, polyurethane plates offer a range of advantages that can improve the efficiency and effectiveness of the screening process. With easy installation and maintenance, as well as superior screening performance, polyurethane plates are a reliable and cost-effective solution for industries that rely on efficient material processing.

How to Choose the Best Good Quality Shaker Circular Vibrating Polyurethane Plate

When it comes to choosing the best quality shaker circular vibrating polyurethane plate, there are several factors to consider. Polyurethane plates are commonly used in vibrating screens to separate materials based on size. They are known for their durability, flexibility, and resistance to abrasion, making them an ideal choice for various industries such as mining, construction, and recycling.

One of the most important factors to consider when choosing a polyurethane plate is the material quality. High-quality polyurethane plates are made from premium-grade polyurethane material that is resistant to wear and tear. This ensures that the plate will last longer and perform better under heavy-duty conditions. It is important to look for plates that are made from virgin polyurethane material, as recycled material may not offer the same level of durability and performance.

Another important factor to consider is the design of the polyurethane plate. The shape and size of the apertures on the plate will determine the efficiency of the screening process. It is important to choose a plate with the right aperture size for the material being processed. Plates with smaller apertures are ideal for fine materials, while plates with larger apertures are better suited for larger materials. Additionally, the design of the plate should allow for easy installation and maintenance, as this will help to prolong the life of the plate.

In addition to material quality and design, it is also important to consider the overall construction of the polyurethane plate. Plates that are reinforced with steel or other materials are more durable and resistant to damage. It is important to choose a plate that is strong enough to withstand the rigors of the application it will be used for. Additionally, plates with a smooth surface finish are less likely to trap material and are easier to clean, which can help to improve overall efficiency.

When choosing a polyurethane plate, it is also important to consider the manufacturer. Reputable manufacturers with a history of producing high-quality products are more likely to provide plates that meet industry standards and specifications. It is important to do research on different manufacturers and read reviews from other customers to ensure that you are choosing a reliable and reputable supplier.

Overall, choosing the best quality shaker circular vibrating polyurethane plate requires careful consideration of material quality, design, construction, and manufacturer. By taking the time to research and compare different options, you can ensure that you are investing in a plate that will provide long-lasting performance and efficiency. Remember to consider the specific requirements of your application and choose a plate that is tailored to meet those needs. With the right polyurethane plate, you can improve the efficiency and productivity of your screening process.