tamaños de pantalla de malla por xunto, fábricas de malla de pantalla vibratoria

Tamaños de pantalla de malla óptimos para diferentes aplicacións no comercio por xunto Cando se trata de escoller o tamaño de pantalla…

Tamaños de pantalla de malla óptimos para diferentes aplicacións no comercio por xunto

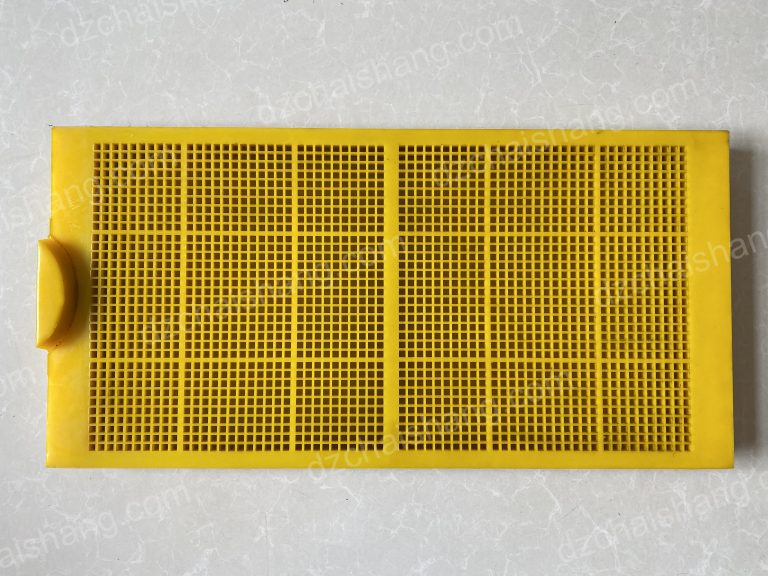

Cando se trata de escoller o tamaño de pantalla de malla adecuado para a súa aplicación específica, hai que ter en conta algúns factores clave. As pantallas de malla úsanse habitualmente nunha variedade de industrias, incluíndo a minería, a agricultura e a construción, por citar algunhas. O tamaño da pantalla de malla que escolla dependerá do tipo de material co que estea a traballar e do resultado desexado do seu proceso de selección.

Nos mercados por xunto, é importante ter acceso a unha ampla gama de tamaños de malla para acomodar as diversas necesidades dos clientes. As fábricas de mallas de pantallas vibratorias xogan un papel crucial ao ofrecer estas opcións ás empresas que buscan comprar pantallas de mallas a granel. Estas fábricas producen pantallas de malla de alta calidade que son duradeiras e fiables, o que as converte nunha opción popular entre os maioristas.

Un dos factores máis importantes a ter en conta á hora de seleccionar un tamaño de pantalla de malla é o tamaño das partículas coas que está a traballar. Por exemplo, se está a filtrar partículas finas, necesitará unha pantalla de malla cun tamaño de abertura máis pequeno para garantir que as partículas non pasen. Por outra banda, se está a traballar con partículas máis grandes, unha pantalla de malla cun tamaño de abertura maior pode ser máis apropiada.

Outro factor a ter en conta é o tipo de material que está a seleccionar. Os diferentes materiais teñen propiedades diferentes, o que pode afectar o proceso de cribado. Por exemplo, os materiais que son propensos a pegarse ou atascarse poden requirir unha pantalla de malla con aberturas máis grandes para evitar bloqueos. Pola contra, os materiais que son máis abrasivos poden requirir unha pantalla de malla con aberturas máis pequenas para soportar o desgaste.

Ademais do tamaño das partículas e do tipo de material, o resultado desexado do proceso de cribado tamén se debe ter en conta ao seleccionar unha pantalla de malla. tamaño. Por exemplo, se buscas separar materiais en fraccións de diferentes tamaños, é posible que necesites varias pantallas de malla con diferentes tamaños de abertura. Por outra banda, se simplemente buscas eliminar partículas de gran tamaño, unha soa pantalla de malla cun tamaño de abertura específico pode ser suficiente.

Os tamaños de pantalla de malla por xunto están dispoñibles nunha ampla gama de opcións para acomodar as diversas necesidades dos clientes. As fábricas de mallas de pantallas vibratorias producen pantallas de mallas de varios tamaños, que van de finas a gruesas, para satisfacer os requisitos específicos de diferentes aplicacións. Estas fábricas utilizan materiais de alta calidade e técnicas de fabricación avanzadas para producir pantallas de malla duradeiras, fiables e eficientes.

En conclusión, seleccionar o tamaño de pantalla de malla óptimo para a súa aplicación específica é fundamental para conseguir o resultado desexado do seu proceso de selección. . Factores como o tamaño de partícula, o tipo de material e o resultado desexado deben terse en conta ao elixir un tamaño de pantalla de malla. Os tamaños de pantalla de malla por xunto están dispoñibles nunha variedade de opcións para satisfacer as diversas necesidades dos clientes, e as fábricas de malla de pantalla vibrante xogan un papel fundamental ao proporcionar estas opcións ás empresas que buscan comprar pantallas de malla a granel. Ao escoller o tamaño de pantalla de malla correcto, podes asegurarte de que o teu proceso de selección sexa eficiente, eficaz e exitoso.

Como elixir a fábrica de mallas de pantallas vibrantes adecuada para a túa empresa

Cando se trata de escoller a fábrica de mallas de pantallas vibrantes adecuada para a súa empresa, hai que ter en conta varios factores. Un dos aspectos máis importantes a ter en conta é o tamaño das pantallas de malla que ofrece a fábrica. Os tamaños de pantalla de malla por xunto poden variar moito, polo que é fundamental atopar unha fábrica que poida proporcionar os tamaños que precisa para a súa aplicación específica.

Antes de comezar a buscar unha fábrica de malla de pantalla vibrante, é esencial determinar o tamaño das pantallas de malla. que funcionará mellor para o teu negocio. O tamaño da pantalla de malla refírese ao número de ocos por polgada lineal. Por exemplo, unha pantalla de 20 mallas terá 20 ocos por polgada lineal. O tamaño da pantalla de malla que elixas dependerá do tipo de material co que esteas a traballar e do tamaño de partícula desexado.

Unha vez que teñas determinado o tamaño das pantallas de malla que necesitas, é hora de comezar a investigar as fábricas de mallas de pantallas vibrantes. Busca fábricas especializadas na produción de pantallas de malla de alta calidade para pantallas vibratorias. Queres traballar cunha fábrica que teña a reputación de producir pantallas de malla duradeiras e fiables que farán fronte ás demandas da túa empresa.

Ao avaliar as posibles fábricas de mallas de pantallas vibratorias, asegúrate de preguntar sobre os materiais que usan para fabricar as súas pantallas de malla. As pantallas de malla de alta calidade adoitan estar feitas de aceiro inoxidable ou outros materiais duradeiros que poden soportar os rigores das operacións de cribado. Evite as fábricas que utilizan materiais de baixa calidade, xa que é máis probable que estas pantallas de malla se desgasten rapidamente e necesiten substitucións frecuentes.

Ademais dos materiais utilizados, ten en conta o proceso de fabricación que emprega a fábrica. Busca fábricas que utilicen tecnoloxía e equipos avanzados para producir as súas pantallas de malla. Unha fábrica que inviste en procesos de fabricación de vangarda é máis probable que produza pantallas de malla de alta calidade que cumpran as túas especificacións.

Finalmente, non esquezas ter en conta o custo das pantallas de malla ao elixir unha fábrica de mallas de pantallas vibratorias. Aínda que é importante atopar unha fábrica que ofreza prezos competitivos, ten coidado coas fábricas que ofrecen prezos que parecen demasiado bos para ser certos. Lembra que obtén o que pagas, polo que paga a pena investir en pantallas de malla de alta calidade que durarán máis tempo e funcionarán mellor a longo prazo.

En conclusión, escoller a fábrica de mallas de pantallas vibrantes adecuada para a túa empresa é unha decisión crucial. que poden afectar a eficiencia e eficacia das súas operacións de selección. Tendo en conta factores como o tamaño da pantalla de malla, os materiais, os procesos de fabricación, o servizo ao cliente e o custo, podes atopar unha fábrica que satisfaga as túas necesidades e axude á túa empresa a ter éxito. Tómese o tempo para investigar e avaliar posibles fábricas antes de tomar unha decisión, e non dubide en facer preguntas e buscar referencias doutros clientes. Coa fábrica adecuada do teu lado, podes asegurarte de que as pantallas de malla de pantallas vibratorias sexan da máis alta calidade e axudarán a que a túa empresa prospere.