shaker mesh,screenwise panel,screens mesh in China UGOL ROSSII & MINING

Exploring the Advantages of shaker mesh in Industrial Applications Shaker mesh, screenwise panel, and screens mesh are integral components in various industrial…

Exploring the Advantages of shaker mesh in Industrial Applications

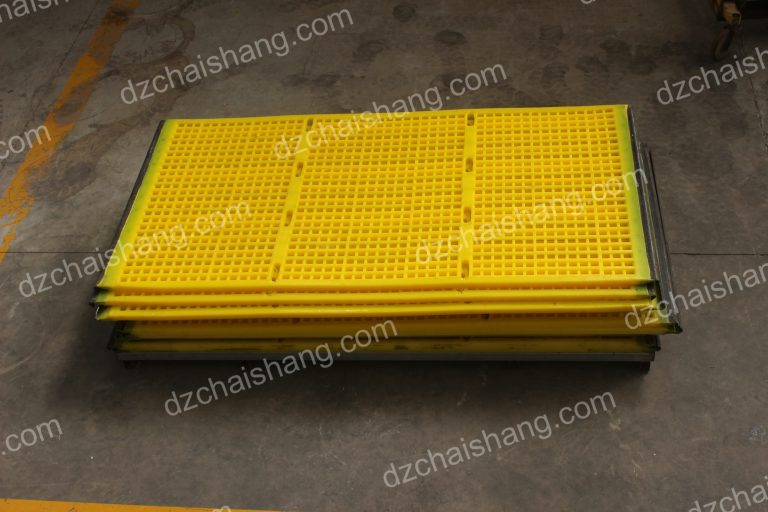

Shaker mesh, screenwise panel, and screens mesh are integral components in various industrial processes, particularly in sectors like mining and construction. These finely woven screens play a crucial role in separating solids from liquids, grading materials by particle size, and facilitating efficient operations across a range of applications. In the realm of industrial equipment, their significance cannot be overstated. Among these, shaker mesh stands out as a versatile and efficient solution, offering a myriad of advantages that enhance productivity and quality in industrial settings. Shaker mesh, often manufactured using high-quality stainless steel, boasts exceptional durability and resistance to corrosion, making it ideal for demanding environments such as mining sites or chemical processing plants. Its robust construction ensures longevity, reducing the need for frequent replacements and thereby minimizing downtime and maintenance costs. This durability is further augmented by advanced manufacturing techniques that result in precise mesh openings and uniformity, ensuring consistent performance over extended periods. One of the primary functions of shaker mesh is its role in the process of solid-liquid separation, commonly employed in industries ranging from oil and gas to wastewater treatment. By effectively filtering out solids while allowing liquids to pass through, shaker mesh facilitates the extraction of valuable resources and the purification of fluids, contributing to enhanced efficiency and environmental sustainability. Its precise mesh size selection enables tailored filtration solutions, catering to specific particle size requirements and ensuring optimal separation efficiency. Moreover, shaker mesh finds extensive use in the classification and grading of materials based on particle size. In industries such as mining and aggregate processing, where the quality and consistency of materials are paramount, screens mesh plays a crucial role in ensuring that only particles of the desired size are processed further, while oversized or undersized particles are efficiently separated. This results in improved product quality, reduced waste, and enhanced overall productivity. The versatility of shaker mesh extends beyond its role in solid-liquid separation and particle classification. In applications where precise control over particle size distribution is critical, such as pharmaceutical manufacturing or food processing, screens mesh offers unparalleled accuracy and reliability. With a wide range of mesh sizes available, ranging from coarse to ultrafine, manufacturers can achieve precise control over product characteristics, ensuring compliance with stringent quality standards and regulatory requirements.The Evolution of screen mesh Technology in China’s UGOL ROSSII & MINING Exhibition

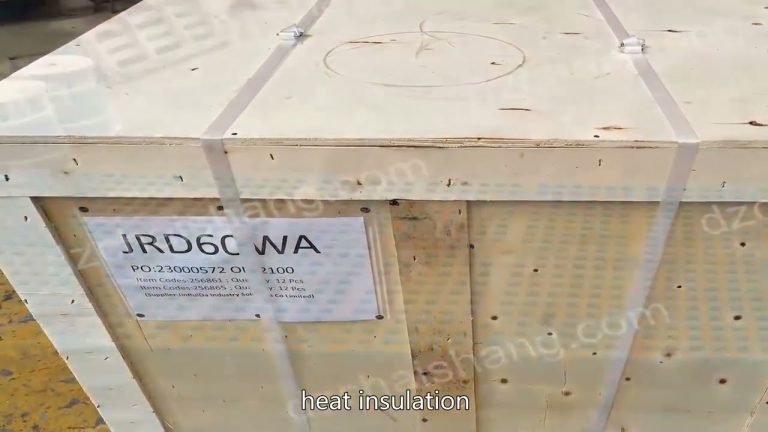

Screen mesh technology has undergone significant evolution, particularly in the context of China’s UGOL ROSSII & MINING Exhibition. This premier event showcases the latest advancements in mining equipment and technologies, including innovations in screen mesh. Among the notable developments featured are Shaker Mesh, Screenwise Panel, and various other screen mesh solutions. Traditionally, screen mesh served a fundamental purpose in mining operations, acting as a barrier to separate valuable minerals from unwanted materials. However, as industries continue to demand greater efficiency and productivity, screen mesh technology has adapted to meet these evolving needs. One notable advancement is the introduction of Shaker Mesh. This innovative mesh design incorporates durable materials and precise engineering to enhance screening performance. By optimizing aperture sizes and wire diameters, Shaker Mesh ensures efficient particle separation while minimizing downtime due to mesh wear and tear. Moreover, the integration of advanced manufacturing techniques has enabled the production of Screenwise Panel, a revolutionary approach to screen mesh design. Screenwise Panel employs modular panels that can be easily installed and replaced, offering unprecedented convenience and flexibility for maintenance personnel. This modular design also allows for customized configurations to suit specific screening requirements, further enhancing operational efficiency. The adoption of high-quality materials, such as stainless steel and polyurethane, further enhances the durability and longevity of screen mesh products. These materials are resistant to corrosion and abrasion, ensuring prolonged service life even in harsh operating conditions. Additionally, advancements in surface treatment technologies have enabled manufacturers to offer screen mesh with superior wear resistance and self-cleaning properties, further reducing maintenance requirements and improving overall productivity. In addition to enhancing performance and durability, screen mesh technology has also evolved to address environmental considerations. Sustainable manufacturing practices, including the use of recycled materials and energy-efficient production processes, are increasingly prioritized in the development of screen mesh solutions. This commitment to sustainability not only aligns with global environmental goals but also reflects the industry’s responsibility to minimize its ecological footprint. Furthermore, advancements in digitalization and automation have transformed the monitoring and maintenance of screen mesh systems. Real-time data analytics and predictive maintenance algorithms enable early detection of potential issues, allowing operators to preemptively address them before they escalate into costly downtime events. Remote monitoring capabilities also facilitate proactive maintenance scheduling, optimizing equipment uptime and maximizing productivity.

As the demand for higher throughput and finer particle separation continues to drive innovation in the mining industry, screen mesh technology will undoubtedly remain at the forefront of these developments. Through ongoing research and development efforts, manufacturers are poised to introduce even more advanced solutions that further elevate screening performance and efficiency.

In conclusion, the evolution of screen mesh technology in China’s UGOL ROSSII & MINING Exhibition exemplifies the industry’s commitment to innovation and continuous improvement. From Shaker Mesh to Screenwise Panel and beyond, these advancements not only enhance operational efficiency and productivity but also underscore the importance of sustainability and environmental stewardship. As mining operations strive to meet the challenges of the 21st century, screen mesh technology will continue to play a vital role in shaping the future of the industry.

Furthermore, advancements in digitalization and automation have transformed the monitoring and maintenance of screen mesh systems. Real-time data analytics and predictive maintenance algorithms enable early detection of potential issues, allowing operators to preemptively address them before they escalate into costly downtime events. Remote monitoring capabilities also facilitate proactive maintenance scheduling, optimizing equipment uptime and maximizing productivity.

As the demand for higher throughput and finer particle separation continues to drive innovation in the mining industry, screen mesh technology will undoubtedly remain at the forefront of these developments. Through ongoing research and development efforts, manufacturers are poised to introduce even more advanced solutions that further elevate screening performance and efficiency.

In conclusion, the evolution of screen mesh technology in China’s UGOL ROSSII & MINING Exhibition exemplifies the industry’s commitment to innovation and continuous improvement. From Shaker Mesh to Screenwise Panel and beyond, these advancements not only enhance operational efficiency and productivity but also underscore the importance of sustainability and environmental stewardship. As mining operations strive to meet the challenges of the 21st century, screen mesh technology will continue to play a vital role in shaping the future of the industry.