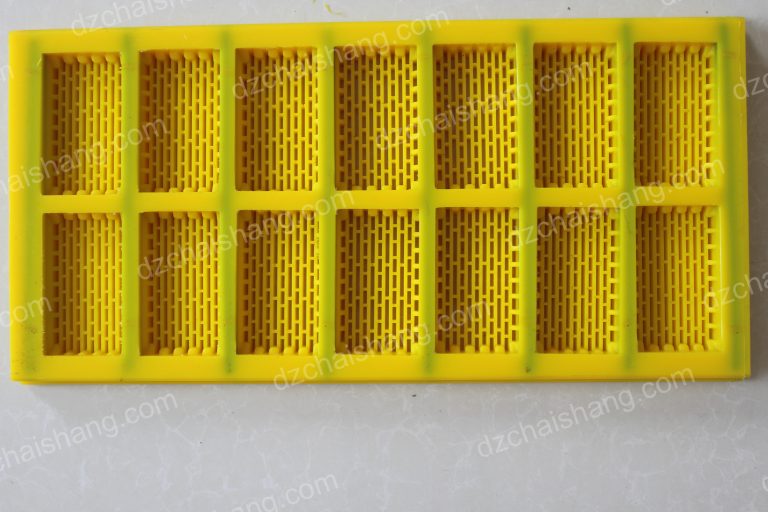

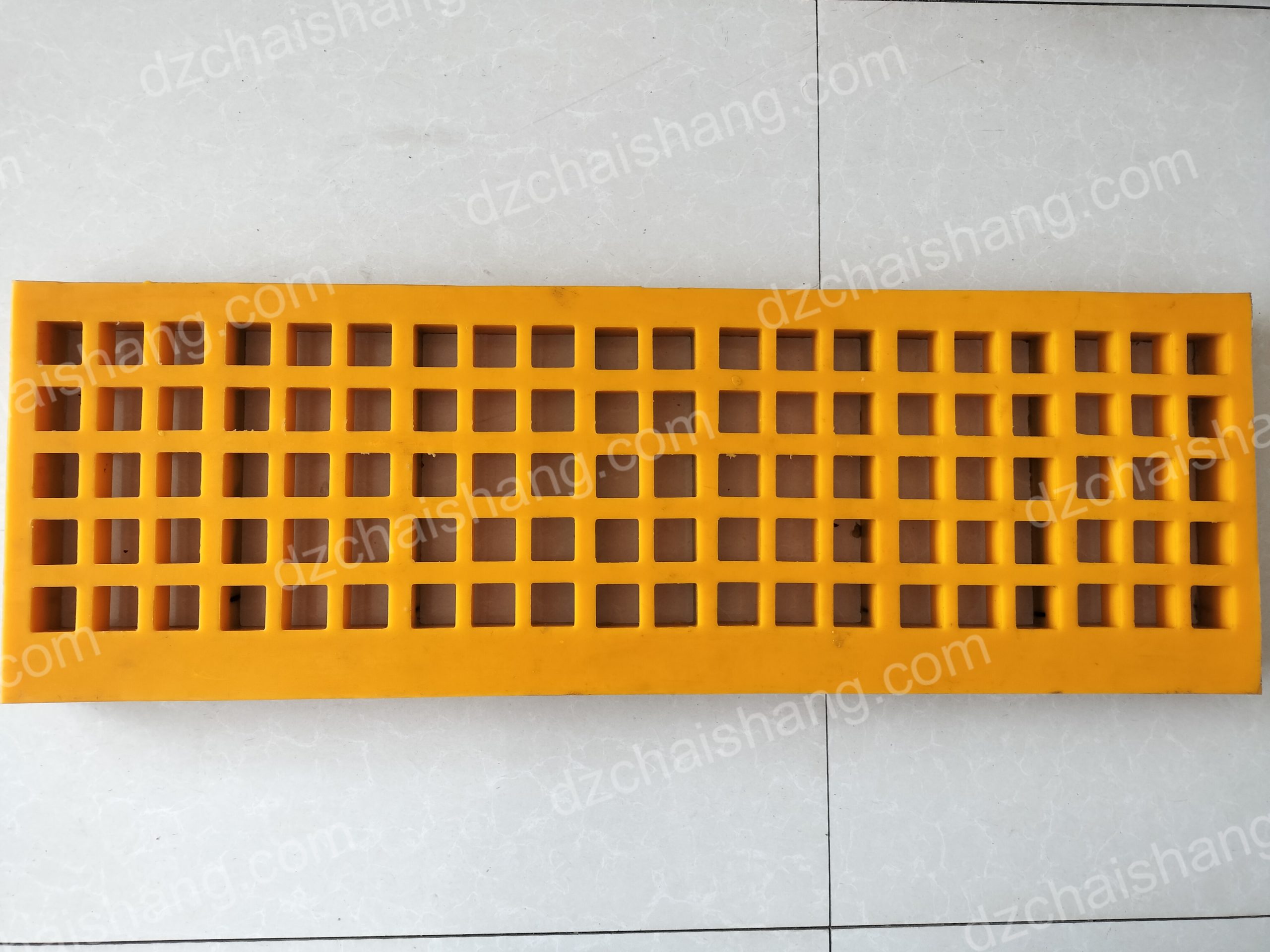

polyurethane screen mesh ,rubber mesh,PU screen mesh

Exploring the Benefits and Applications of polyurethane screen mesh Polyurethane screen mesh, also known as pu screen mesh, is a type of…

Exploring the Benefits and Applications of polyurethane screen mesh

Polyurethane screen mesh, also known as pu screen mesh, is a type of screening material that is widely used in various industries due to its exceptional durability and versatility. This article aims to explore the benefits and applications of polyurethane screen mesh, shedding light on why it has become a preferred choice for many businesses. One of the primary advantages of polyurethane screen mesh is its superior durability. Unlike traditional metal screens, polyurethane screen mesh is resistant to wear and tear, making it an ideal choice for industries that require heavy-duty screening. The material’s resilience to abrasion and corrosion ensures that it can withstand harsh conditions, thereby reducing the need for frequent replacements and maintenance. This, in turn, leads to significant cost savings in the long run. Another notable benefit of polyurethane screen mesh is its flexibility. The material can be molded into various shapes and sizes to meet specific requirements. This flexibility allows for a wide range of applications, from mining and quarrying to recycling and waste management. Furthermore, the elasticity of polyurethane screen mesh enables it to absorb impact, reducing the risk of breakage and prolonging its lifespan. In addition to its durability and flexibility, polyurethane screen mesh also offers excellent noise reduction properties. The material’s ability to dampen sound vibrations makes it an ideal choice for industries that prioritize noise control. This feature not only contributes to a safer and more comfortable working environment but also helps companies comply with noise regulations. Polyurethane screen mesh also stands out for its environmental friendliness. The material is recyclable, which aligns with the growing emphasis on sustainability in today’s business landscape. By choosing polyurethane screen mesh, companies can contribute to environmental conservation while also enhancing their corporate image. The benefits of polyurethane screen mesh extend to its performance as well. The material’s high screening efficiency ensures that it can effectively separate different types of materials, regardless of their size or shape. This makes polyurethane screen mesh a reliable solution for industries that require precise and efficient screening. Given these benefits, it is no surprise that polyurethane screen mesh has found widespread application in various industries. In the mining and quarrying sector, for instance, the material is used to screen and separate different types of rocks and minerals. Its durability and high screening efficiency make it an ideal choice for this demanding industry. In the recycling and waste management sector, polyurethane screen mesh is used to sort and separate different types of waste materials. Its flexibility allows it to accommodate a wide range of waste types, while its durability ensures that it can withstand the rigors of waste handling.

In conclusion, polyurethane screen mesh offers a host of benefits that make it a superior alternative to traditional screening materials. Its durability, flexibility, noise reduction properties, environmental friendliness, and high screening efficiency make it a versatile solution for a wide range of industries. Whether it’s for mining and quarrying or recycling and waste management, polyurethane screen mesh is a reliable and cost-effective choice that delivers exceptional performance.