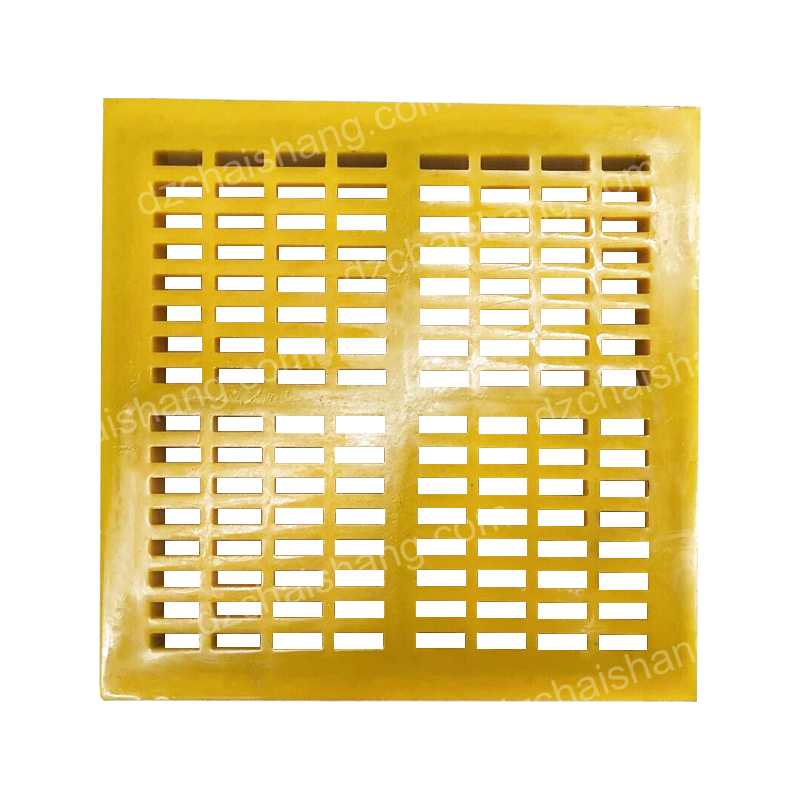

high frequency screen,Polyurethane fine screen

Benefits of Using high frequency screens in Mineral Processing High frequency screens are an essential tool in the mineral processing industry, offering…

Benefits of Using high frequency screens in Mineral Processing

High frequency screens are an essential tool in the mineral processing industry, offering a range of benefits that can significantly improve the efficiency and effectiveness of mineral separation processes. One of the key advantages of high frequency screens is their ability to efficiently separate fine particles from larger particles, resulting in a more precise and accurate separation process.

The high frequency screen operates at a high frequency, typically between 3600 and 7200 RPM, which allows for the efficient separation of particles based on size and shape. This high frequency vibration helps to create a thin bed of particles on the screen surface, allowing for the effective separation of fine particles from larger particles. This results in a higher quality final product, as the fine particles are effectively removed from the feed material. In addition to their ability to separate fine particles, high frequency screens also offer a number of other benefits in mineral processing. One of the key advantages of high frequency screens is their ability to handle high tonnages of material, making them ideal for large-scale mineral processing operations. This high capacity allows for the efficient processing of large volumes of material, resulting in increased productivity and reduced processing times. Another benefit of high frequency screens is their ability to operate at a lower angle than traditional screens, which helps to improve the efficiency of the screening process. By operating at a lower angle, high frequency screens can effectively screen a larger volume of material in a shorter amount of time, resulting in increased throughput and improved overall efficiency. High frequency screens are also known for their durability and reliability, making them a cost-effective option for mineral processing operations. The polyurethane fine screen used in high frequency screens is highly resistant to wear and abrasion, ensuring a long service life and minimal maintenance requirements. This durability helps to reduce downtime and maintenance costs, resulting in increased profitability for mineral processing operations.

In addition to their durability, high frequency screens are also known for their versatility and flexibility. These screens can be easily customized to meet the specific needs of a wide range of mineral processing applications, making them a versatile and adaptable option for processing a variety of materials. Whether processing coal, iron ore, or other minerals, high frequency screens can be tailored to meet the unique requirements of each application. Overall, high frequency screens offer a range of benefits that can significantly improve the efficiency and effectiveness of mineral processing operations. From their ability to separate fine particles to their high capacity and durability, high frequency screens are a valuable tool for any mineral processing operation. By investing in high frequency screens, mineral processing operations can improve their productivity, reduce processing times, and increase profitability.