Panel de pantalla de poliuretano de alta elasticidade, malla de pantalla vibrante de poliuretano a prezo de fábrica

Panel de pantalla de poliuretano de alta elasticidade: explorando a durabilidade e a rendibilidade na fabricación de mallas de malla vibratoria de…

Panel de pantalla de poliuretano de alta elasticidade: explorando a durabilidade e a rendibilidade na fabricación de mallas de malla vibratoria de poliuretano

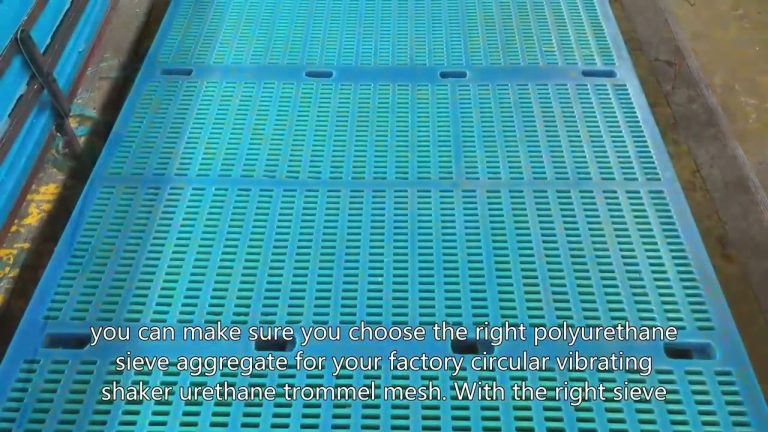

O poliuretano, un polímero sintético versátil, é coñecido pola súa excepcional elasticidade e durabilidade, polo que é un material ideal para numerosas aplicacións industriais. Entre os seus diversos usos, o poliuretano ocupa un lugar destacado na fabricación de paneis de criba vibrante, que son compoñentes críticos nos procesos de selección e cribado en sectores como a minería, a agricultura e a reciclaxe. Estes paneis de pantalla de poliuretano de alta elasticidade combinan resistencia coa eficiencia, ofrecendo un avance significativo sobre os materiais tradicionais como o fío metálico ou a goma.

A fabricación destes paneis de pantalla de poliuretano aproveita as calidades inherentes do polímero para proporcionar características de rendemento superiores. A alta resistencia á tracción do poliuretano e a excelente resistencia á abrasión fan que sexa especialmente adecuado para aplicacións onde o desgaste é frecuente. Estas propiedades garanten que os paneis de pantalla poidan soportar as condicións rigorosas das pantallas vibratorias, que a miúdo funcionan continuamente en ambientes duros. A natureza elástica do material permítelle absorber o impacto e resistir a deformación, mantendo así a súa integridade estrutural no tempo e reducindo a necesidade de substitucións frecuentes.

Ademais, o potencial de personalización do poliuretano é unha vantaxe notable. Os fabricantes poden axustar a formulación para cumprir requisitos específicos, como o tamaño dos poros, a forma e a flexibilidade. Esta personalización mellora a funcionalidade do material optimizándoo para varias tarefas de cribado, xa se trate de partículas finas na produción de alimentos ou de materiais máis grandes no procesamento de minerais. A capacidade de adaptar as pantallas a aplicacións específicas non só mellora a eficiencia do proceso de cribado, senón que tamén contribúe á rendibilidade global da operación.

A rendibilidade é de feito outro atributo atractivo dos paneis de pantalla vibrante de poliuretano. Aínda que o investimento inicial nestas pantallas de alta calidade pode ser superior ao dos materiais convencionais, o aforro a longo prazo é significativo. A durabilidade e a vida útil máis longa do poliuretano reducen a frecuencia de substitucións da pantalla, diminuíndo así o tempo de inactividade e os custos de mantemento. Ademais, a mellora da eficiencia do proceso de selección pode levar a un maior rendemento e unha mellor calidade do produto final, que son factores críticos para a rendibilidade nas operacións industriais.

O impacto ambiental do uso de poliuretano tamén merece unha consideración. A diferenza dalgúns materiais tradicionais que poden degradarse en compoñentes prexudiciais para o medio ambiente, as pantallas de poliuretano están deseñadas para a estabilidade e a lonxevidade, o que contribúe á redución de residuos. Ademais, os continuos avances na tecnoloxía do poliuretano están enfocados a aumentar a reciclabilidade do material, o que apoia os esforzos cara a prácticas de fabricación máis sostibles.

En conclusión, os paneis de pantalla de poliuretano de alta elasticidade representan unha innovación significativa no campo da criba industrial. A súa capacidade de combinar durabilidade coa elasticidade non só reúne as esixentes condicións das pantallas vibrantes, senón que tamén ofrece unha maior rendibilidade mediante un mantemento reducido e unha eficiencia operativa. Mentres as industrias seguen a buscar solucións que equilibren o rendemento co custo e as consideracións ambientais, a malla de pantalla vibrante de poliuretano destaca como unha opción prometedora. O continuo desenvolvemento e refinamento dos materiais de poliuretano probablemente favorecerá a súa adopción en varios sectores, reforzando o seu estatus como material fundamental na fabricación moderna.