dewatering screen design,vibrating screen mesh quotes

dewatering screen Design: Key Considerations for Optimal Performance Dewatering screens are essential equipment in the mining and aggregate industries, used to remove…

dewatering screen Design: Key Considerations for Optimal Performance

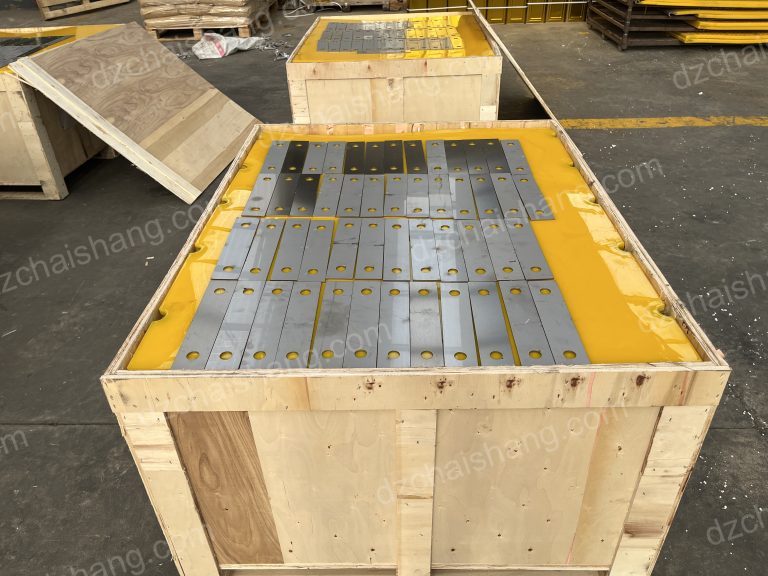

Dewatering screens are essential equipment in the mining and aggregate industries, used to remove excess moisture from materials before further processing. The design of a dewatering screen plays a crucial role in its performance and efficiency. In this article, we will discuss key considerations for designing a dewatering screen that ensures optimal performance.One of the most important factors to consider when designing a dewatering screen is the size and shape of the screen openings. The size of the openings will determine the amount of material that can pass through the screen, while the shape of the openings will affect the efficiency of the dewatering process. It is essential to choose the right combination of size and shape to achieve the desired level of dewatering. Another critical aspect of dewatering screen design is the angle of inclination. The angle at which the screen is inclined will impact the speed at which the material moves across the screen surface and the efficiency of the dewatering process. A steeper angle will result in faster material movement but may also lead to reduced dewatering efficiency. It is important to find the optimal angle of inclination that balances material flow and dewatering performance.

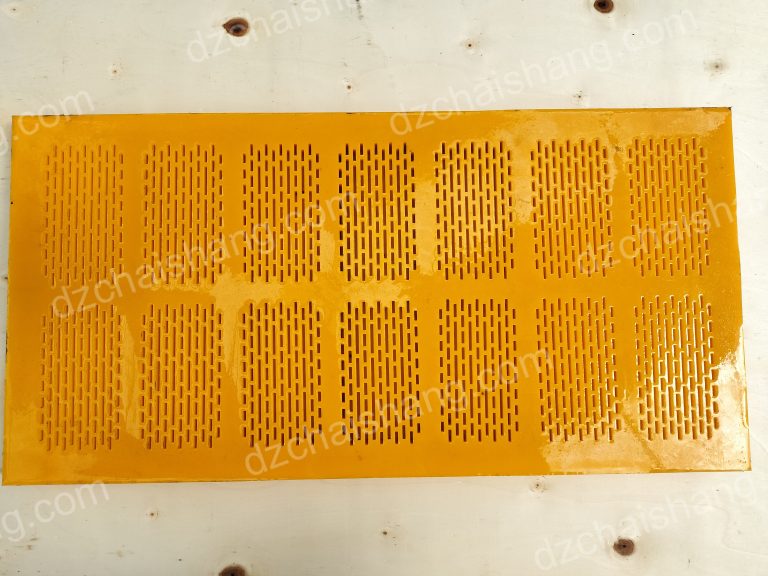

In addition to size, shape, and angle of inclination, the design of the vibrating screen mesh is also crucial for optimal dewatering performance. The mesh should be selected based on the size and type of material being processed, as well as the desired level of dewatering. A finer mesh will remove more moisture but may also reduce throughput, while a coarser mesh will allow for higher throughput but may not achieve the desired level of dewatering. It is essential to choose the right mesh size and type to achieve the best results.

When designing a dewatering screen, it is also important to consider the vibration frequency and amplitude. The vibration of the screen helps to move the material across the screen surface and facilitate the dewatering process. The frequency and amplitude of the vibration should be carefully adjusted to achieve optimal material movement and dewatering efficiency. It is essential to find the right balance between vibration frequency and amplitude to maximize performance.

In conclusion, designing a dewatering screen requires careful consideration of several key factors, including the size and shape of the screen openings, the angle of inclination, the vibrating screen mesh, and the vibration frequency and amplitude. By taking these factors into account and finding the right balance between them, it is possible to design a dewatering screen that delivers optimal performance and efficiency. With the right design, a dewatering screen can effectively remove excess moisture from materials and improve overall processing efficiency in mining and aggregate operations.

In addition to size, shape, and angle of inclination, the design of the vibrating screen mesh is also crucial for optimal dewatering performance. The mesh should be selected based on the size and type of material being processed, as well as the desired level of dewatering. A finer mesh will remove more moisture but may also reduce throughput, while a coarser mesh will allow for higher throughput but may not achieve the desired level of dewatering. It is essential to choose the right mesh size and type to achieve the best results.

When designing a dewatering screen, it is also important to consider the vibration frequency and amplitude. The vibration of the screen helps to move the material across the screen surface and facilitate the dewatering process. The frequency and amplitude of the vibration should be carefully adjusted to achieve optimal material movement and dewatering efficiency. It is essential to find the right balance between vibration frequency and amplitude to maximize performance.

In conclusion, designing a dewatering screen requires careful consideration of several key factors, including the size and shape of the screen openings, the angle of inclination, the vibrating screen mesh, and the vibration frequency and amplitude. By taking these factors into account and finding the right balance between them, it is possible to design a dewatering screen that delivers optimal performance and efficiency. With the right design, a dewatering screen can effectively remove excess moisture from materials and improve overall processing efficiency in mining and aggregate operations.