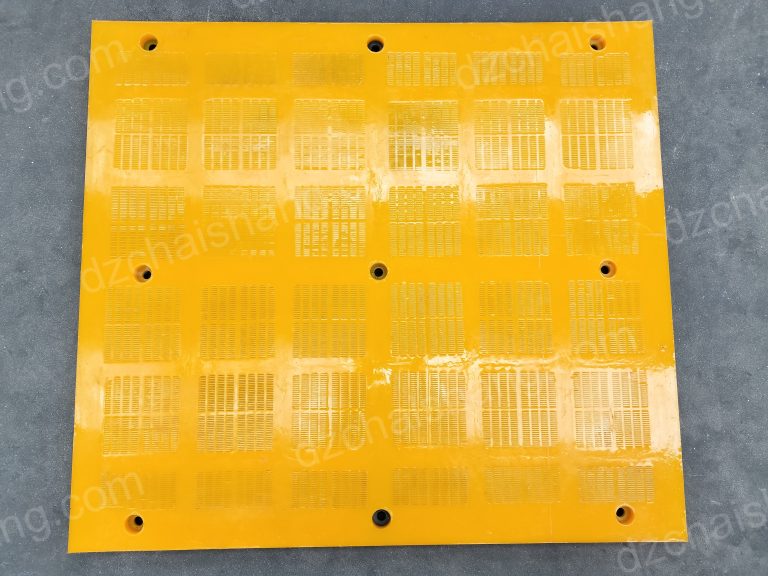

fine polyurethane screen,mining polyurethane screens

Benefits of Using Fine polyurethane screens in mining Operations Fine polyurethane screens are becoming increasingly popular in the mining industry due to…

Benefits of Using Fine polyurethane screens in mining Operations

Fine polyurethane screens are becoming increasingly popular in the mining industry due to their numerous benefits and advantages over traditional metal screens. These screens are made from a durable and flexible material that offers superior performance and longevity in harsh mining environments. In this article, we will explore the benefits of using fine polyurethane screens in mining operations. One of the key advantages of fine polyurethane screens is their high abrasion resistance. Polyurethane is a tough material that can withstand the wear and tear of constant use in mining applications. This means that polyurethane screens have a longer lifespan compared to traditional metal screens, reducing the need for frequent replacements and maintenance. In addition to their durability, fine polyurethane screens also offer excellent screening efficiency. The fine apertures of these screens allow for precise separation of materials, resulting in higher quality products and increased productivity. This is especially important in mining operations where the quality of the final product is crucial for meeting industry standards and customer requirements. Another benefit of using fine polyurethane screens is their flexibility and versatility. These screens can be easily customized to meet specific sizing and screening requirements, making them suitable for a wide range of applications in the mining industry. Whether you are screening coal, iron ore, or other minerals, fine polyurethane screens can be tailored to suit your needs. Furthermore, fine polyurethane screens are lightweight and easy to install, reducing downtime and labor costs associated with screen replacement. Their flexibility also allows for easy handling and transportation, making them a convenient choice for mining operations that require frequent screen changes. In terms of maintenance, fine polyurethane screens are easy to clean and maintain. Unlike metal screens that can rust or corrode over time, polyurethane screens are resistant to chemicals and moisture, ensuring long-lasting performance in harsh mining environments. This means less downtime and lower maintenance costs for mining operators. Overall, the benefits of using fine polyurethane screens in mining operations are clear. From their high abrasion resistance and screening efficiency to their flexibility and ease of maintenance, polyurethane screens offer a cost-effective and reliable solution for screening applications in the mining industry. By investing in fine polyurethane screens, mining operators can improve their productivity, reduce downtime, and achieve higher quality products. In conclusion, fine polyurethane screens are a valuable asset for mining operations looking to enhance their screening processes. With their durability, efficiency, and versatility, polyurethane screens offer a superior alternative to traditional metal screens. By choosing fine polyurethane screens, mining operators can benefit from increased productivity, reduced maintenance costs, and improved product quality.How to Properly Maintain and Extend the Lifespan of mining polyurethane screens

Polyurethane screens are a crucial component in the mining industry, as they play a vital role in the screening and separation of materials. These screens are known for their durability, flexibility, and resistance to abrasion, making them a popular choice for mining operations. However, like any equipment, polyurethane screens require proper maintenance to ensure optimal performance and longevity. One of the key factors in maintaining polyurethane screens is regular cleaning. Over time, materials can build up on the surface of the screen, reducing its effectiveness and potentially causing damage. To prevent this, it is important to clean the screens regularly using a mild detergent and water. Avoid using harsh chemicals or abrasive materials, as these can cause damage to the screen’s surface. In addition to regular cleaning, it is also important to inspect the screens for any signs of wear or damage. Look for tears, holes, or areas of excessive wear, as these can impact the screen’s performance. If any damage is found, it is important to repair or replace the screen as soon as possible to prevent further issues. Another important aspect of maintaining polyurethane screens is proper storage. When not in use, screens should be stored in a clean, dry environment to prevent damage. Avoid stacking screens on top of each other, as this can cause deformation and reduce their effectiveness. Instead, store screens flat or on their sides to maintain their shape and integrity. In addition to regular cleaning, inspection, and storage, it is also important to handle polyurethane screens with care. Avoid dropping or mishandling screens, as this can cause damage and reduce their lifespan. When installing or removing screens, take care to follow proper procedures to prevent damage.Proper maintenance of polyurethane screens is essential for extending their lifespan and ensuring optimal performance. By following these tips, mining operations can maximize the efficiency and effectiveness of their screens, ultimately leading to increased productivity and profitability.

In conclusion, polyurethane screens are a valuable asset in the mining industry, and proper maintenance is essential for extending their lifespan and ensuring optimal performance. By regularly cleaning, inspecting, storing, and handling screens with care, mining operations can maximize the efficiency and effectiveness of their equipment. Investing time and effort into maintaining polyurethane screens will pay off in the long run, leading to increased productivity and profitability for mining operations.

In conclusion, polyurethane screens are a valuable asset in the mining industry, and proper maintenance is essential for extending their lifespan and ensuring optimal performance. By regularly cleaning, inspecting, storing, and handling screens with care, mining operations can maximize the efficiency and effectiveness of their equipment. Investing time and effort into maintaining polyurethane screens will pay off in the long run, leading to increased productivity and profitability for mining operations.