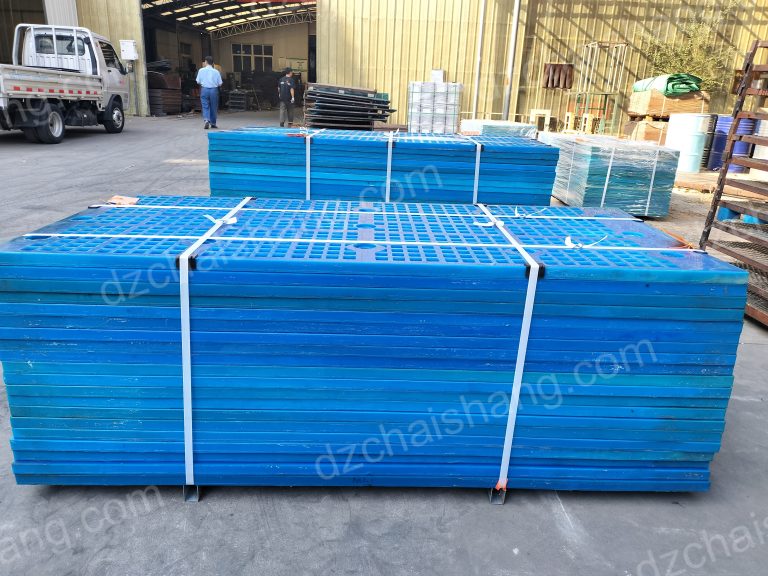

tensioned screen sieve,PU panel,urethane sieve

Exploring the Efficiency of tensioned screen Sieve, pu panel, and urethane Sieve in Material Screening Processes Material screening is a critical process…

Exploring the Efficiency of tensioned screen Sieve, pu panel, and urethane Sieve in Material Screening Processes

Material screening is a critical process in various industries, including mining, construction, and recycling. It involves the separation of materials based on their size, a process that requires the use of specialized equipment. Among the most effective tools for this task are the tensioned SCREEN SIEVE, PU panel, and urethane sieve. These tools have been lauded for their efficiency and durability, making them a preferred choice for many professionals in the field. The tensioned screen sieve is a popular choice due to its unique design and functionality. It is characterized by a wire mesh that is tensioned in a frame, creating a flat and tight surface. This design allows for accurate separation of materials, as the tension ensures that the openings in the mesh remain consistent in size. Furthermore, the tensioned screen sieve is known for its durability. The tensioning of the mesh makes it resistant to wear and tear, ensuring that it can withstand the rigors of heavy-duty material screening. Transitioning to the PU panel, it is a screening tool made from polyurethane, a material known for its strength and resilience. The PU panel is designed to handle high-impact applications, making it ideal for screening heavy materials. Its durability is further enhanced by its resistance to abrasion, corrosion, and weathering. This means that the PU panel can maintain its efficiency even in harsh operating conditions. Moreover, the PU panel is flexible, allowing it to be used in various screening applications. It can be customized to fit different screening machines and can handle a wide range of material sizes.

Lastly, the urethane sieve is another efficient tool for material screening. Like the PU panel, it is made from polyurethane, giving it similar strength and durability characteristics. However, the urethane sieve stands out due to its unique properties. It is highly resistant to wear and tear, thanks to its high tensile strength. This makes it suitable for long-term use in material screening processes. Additionally, the urethane sieve is known for its precision. It can accurately separate materials of different sizes, ensuring that the screening process is efficient and effective.