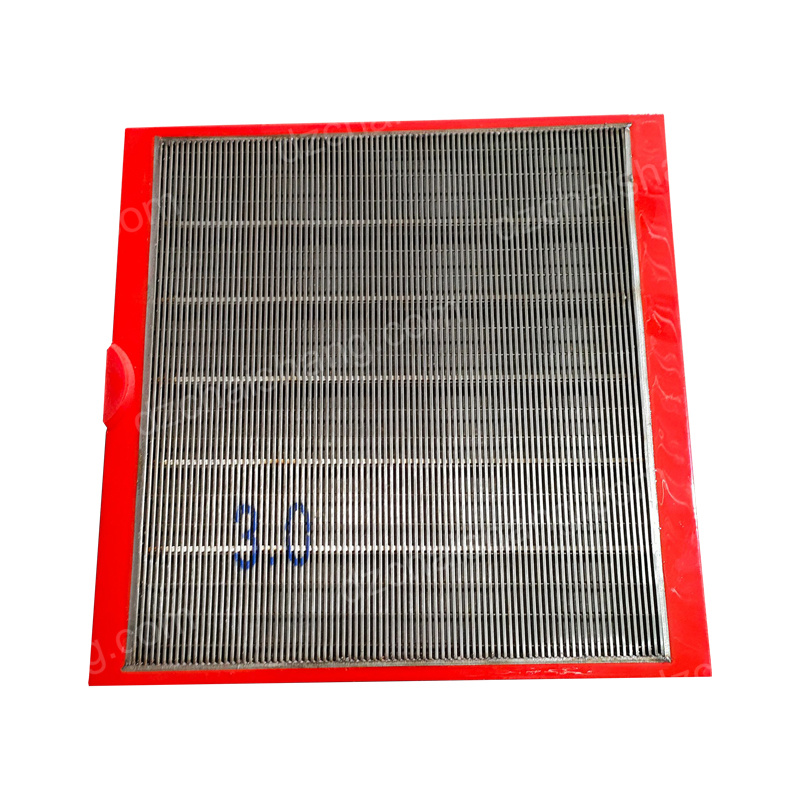

polyurethane screening star,pu screen,polyurethane mining screens

Advantages of Using polyurethane screening Stars in mining Operations Polyurethane screening stars, also known as PU screens or polyurethane mining screens, have…

Advantages of Using polyurethane screening Stars in mining Operations

Polyurethane screening stars, also known as PU screens or polyurethane mining screens, have become increasingly popular in the mining industry due to their numerous advantages over traditional screening materials. These innovative screens are designed to enhance the efficiency and effectiveness of mining operations, making them a valuable asset for companies looking to optimize their processes. One of the primary benefits of using polyurethane screening stars is their exceptional durability. Polyurethane is a highly resilient material that is resistant to abrasion, tearing, and impact. This makes it ideal for use in harsh mining environments where screens are subjected to heavy loads and abrasive materials. The longevity of polyurethane screens translates to reduced downtime for maintenance and replacement, ultimately leading to cost savings and increased productivity for mining operations. In addition to their durability, polyurethane screening stars offer superior performance in terms of screening efficiency. The flexibility of the material allows for better vibration and movement of the screen, which enhances the separation and classification of materials. This results in a more accurate and consistent particle size distribution, which is crucial for the quality control of the extracted minerals. Furthermore, the smooth surface of polyurethane screens minimizes the likelihood of blinding and pegging, common issues that can hinder the screening process in traditional wire mesh screens.