mesh screen price,strongest screen mesh,polyurethane screen panel

Comparing Prices: mesh screen vs polyurethane screen panel In the realm of industrial screening, the choice of screening material plays a pivotal…

Comparing Prices: mesh screen vs polyurethane screen panel

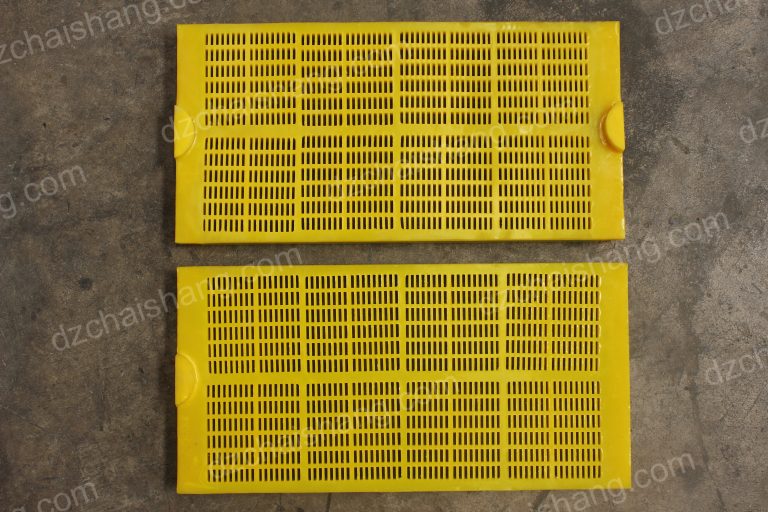

In the realm of industrial screening, the choice of screening material plays a pivotal role in determining both the efficiency and longevity of the screening process. Two of the most popular materials in this domain are mesh screens and polyurethane screen panels. Each of these materials boasts unique properties and advantages, making the decision between them a matter of matching the right material to the specific needs of the application. This article aims to shed light on the comparative aspects of mesh screen and polyurethane screen panel, focusing on their prices, durability, and overall performance. Mesh screens, traditionally made from metal wires or synthetic fibers, are renowned for their versatility and adaptability to various screening needs. The price of mesh screens can vary significantly depending on the material used (e.g., stainless steel, aluminum, or polyester) and the mesh size. Generally, metal mesh screens are more expensive than their synthetic counterparts due to the cost of raw materials and the manufacturing process involved. However, the strength and durability offered by metal mesh screens often justify their higher price point, especially in applications where abrasion and corrosion resistance are paramount. Transitioning from the conventional mesh screen, polyurethane screen panels introduce a modern approach to screening with their robust construction and innovative design. Polyurethane, a type of polymer, is known for its exceptional resistance to wear, tear, and environmental factors, making it an ideal material for harsh screening conditions. The price of polyurethane screen panels tends to be higher than that of standard mesh screens. This is attributed to the complex manufacturing process and the superior durability and longevity that polyurethane offers. Despite the initial investment, many industries prefer polyurethane screen panels for their cost-effectiveness over time, as they often require fewer replacements and maintenance interventions.

When discussing the strongest screen mesh, it is essential to consider the material and weave pattern. Metal mesh screens, particularly those made from high-tensile stainless steel, are considered among the strongest available. These screens are capable of withstanding high levels of mechanical stress and are less likely to tear or puncture compared to synthetic meshes. The strength of a mesh screen is crucial in applications where the material being screened is abrasive or heavy, as it directly impacts the screen’s lifespan and the quality of the screening process.

On the other hand, polyurethane screen panels are celebrated for their resilience and flexibility. Unlike rigid metal screens, Polyurethane Panels can absorb impact and return to their original shape, a property that significantly reduces the risk of damage and extends the panel’s service life. This elasticity, combined with polyurethane’s inherent resistance to wear and tear, positions polyurethane screen panels as a strong contender in the quest for the most durable screening solution.

In conclusion, the choice between mesh screens and polyurethane screen panels hinges on a careful consideration of price, strength, and the specific requirements of the screening application. While mesh screens offer a cost-effective solution with variable strength options, polyurethane screen panels stand out for their unmatched durability and performance in challenging conditions. Ultimately, the decision should align with the operational priorities and budget constraints of the user, ensuring that the selected screening material delivers the desired balance of efficiency, longevity, and cost-effectiveness.

Transitioning from the conventional mesh screen, polyurethane screen panels introduce a modern approach to screening with their robust construction and innovative design. Polyurethane, a type of polymer, is known for its exceptional resistance to wear, tear, and environmental factors, making it an ideal material for harsh screening conditions. The price of polyurethane screen panels tends to be higher than that of standard mesh screens. This is attributed to the complex manufacturing process and the superior durability and longevity that polyurethane offers. Despite the initial investment, many industries prefer polyurethane screen panels for their cost-effectiveness over time, as they often require fewer replacements and maintenance interventions.

When discussing the strongest screen mesh, it is essential to consider the material and weave pattern. Metal mesh screens, particularly those made from high-tensile stainless steel, are considered among the strongest available. These screens are capable of withstanding high levels of mechanical stress and are less likely to tear or puncture compared to synthetic meshes. The strength of a mesh screen is crucial in applications where the material being screened is abrasive or heavy, as it directly impacts the screen’s lifespan and the quality of the screening process.

On the other hand, polyurethane screen panels are celebrated for their resilience and flexibility. Unlike rigid metal screens, Polyurethane Panels can absorb impact and return to their original shape, a property that significantly reduces the risk of damage and extends the panel’s service life. This elasticity, combined with polyurethane’s inherent resistance to wear and tear, positions polyurethane screen panels as a strong contender in the quest for the most durable screening solution.

In conclusion, the choice between mesh screens and polyurethane screen panels hinges on a careful consideration of price, strength, and the specific requirements of the screening application. While mesh screens offer a cost-effective solution with variable strength options, polyurethane screen panels stand out for their unmatched durability and performance in challenging conditions. Ultimately, the decision should align with the operational priorities and budget constraints of the user, ensuring that the selected screening material delivers the desired balance of efficiency, longevity, and cost-effectiveness.

Identifying the Strongest Screen Mesh: A Comprehensive Guide

Identifying the Strongest Screen Mesh: A Comprehensive Guide In the world of industrial screening, the strength and durability of mesh screens are paramount. These screens are essential in various applications, from mining and quarrying to aggregate processing and waste management. As such, understanding the factors that contribute to the strength of a screen mesh, as well as its price, is crucial for businesses looking to invest in reliable screening solutions. When considering the price of a mesh screen, it’s important to recognize that cost is often a reflection of quality and longevity. The strongest screen meshes are typically made from materials that can withstand heavy loads, abrasive materials, and the rigors of continuous use. These materials include stainless steel, high-tensile steel, and polyurethane, each offering unique benefits and price points. Stainless steel mesh screens are highly regarded for their resistance to corrosion and heat. They are suitable for use in a variety of environments, especially those prone to moisture or where hygiene is a concern. The price of stainless steel mesh screens can be higher than other materials due to their superior durability and resistance properties. High-tensile steel screens are another option for those seeking strength. These screens are characterized by their ability to resist high forces without stretching or breaking. This makes them ideal for heavy-duty applications where the screen is subjected to significant mechanical stress. The cost of high-tensile steel mesh screens is often justified by their performance and lifespan, providing value over time. Polyurethane screen panels represent a modern innovation in screening technology. These panels are renowned for their elasticity, which allows them to absorb impact and reduce the likelihood of holes and tears. polyurethane screens are particularly effective in wet screening applications, as they resist water and other liquids. While the initial investment in polyurethane screen panels may be higher than traditional wire mesh, their durability and efficiency can lead to reduced maintenance costs and downtime, ultimately offering a favorable return on investment.When evaluating the strongest screen mesh for a particular application, it’s essential to consider not only the material but also the weave pattern and wire diameter. A tighter weave and thicker wire will generally result in a stronger mesh, but this also impacts the screen’s open area and, consequently, its screening capacity. Therefore, it’s a delicate balance between strength and functionality that must be struck to achieve optimal results. Moreover, the manufacturing process and quality control measures employed by the screen producer can significantly influence the strength of the final product. Reputable manufacturers invest in advanced technologies and rigorous testing to ensure their screens meet the highest standards of quality and performance. In conclusion, the price of a mesh screen is a complex interplay of material choice, design, and manufacturing quality. The strongest screen meshes are those that can endure the demands of their intended use while maintaining their integrity over time. Stainless steel, high-tensile steel, and polyurethane screen panels each offer distinct advantages that cater to different screening needs. By carefully assessing these factors, businesses can make informed decisions that balance cost with performance, ensuring they select a screen mesh that provides both strength and value. As the industry continues to evolve, the quest for the strongest screen mesh will remain a critical consideration for those seeking to optimize their screening operations.