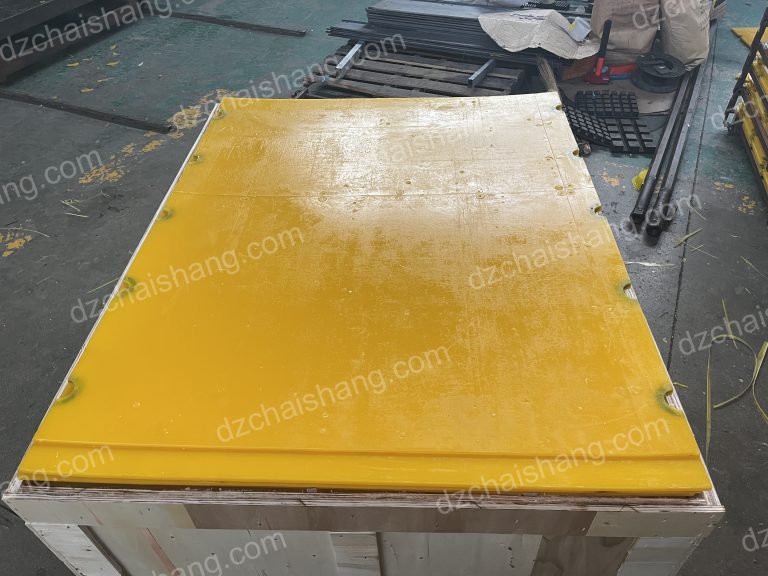

dewatering screen mesh panel,mining polyurethane screen

Benefits of Using dewatering screen mesh panel in mining Operations Dewatering screen mesh panels are an essential component in mining operations, particularly…

Benefits of Using dewatering screen mesh panel in mining Operations

Dewatering screen mesh panels are an essential component in mining operations, particularly in the process of separating solids from liquids. These panels are made from polyurethane, a durable and flexible material that is ideal for use in harsh mining environments. The benefits of using dewatering screen mesh panels in mining operations are numerous and can greatly improve the efficiency and effectiveness of the dewatering process. One of the primary benefits of using dewatering screen mesh panels is their ability to effectively separate solids from liquids. The mesh panels are designed to allow water to pass through while trapping solid particles, resulting in a cleaner and more efficient dewatering process. This is crucial in mining operations where water management is a key concern, as the removal of solids from water can help reduce the environmental impact of mining activities. In addition to their ability to separate solids from liquids, dewatering screen mesh panels are also highly durable and long-lasting. Polyurethane is a resilient material that can withstand the harsh conditions of mining operations, including high temperatures, abrasive materials, and heavy loads. This durability ensures that the mesh panels will continue to perform effectively over time, reducing the need for frequent replacements and maintenance.

Furthermore, dewatering screen mesh panels are easy to install and maintain, making them a cost-effective solution for mining operations. The panels can be quickly and easily installed on existing dewatering equipment, allowing for minimal downtime and disruption to mining activities. Additionally, the low maintenance requirements of polyurethane mesh panels mean that they can be easily cleaned and maintained, further reducing operational costs.

Another benefit of using dewatering screen mesh panels in mining operations is their versatility. The panels can be customized to meet the specific needs of each mining operation, including different mesh sizes and configurations. This flexibility allows for greater control over the dewatering process, ensuring that the desired level of separation is achieved.

Additionally, dewatering screen mesh panels are environmentally friendly, as they help to reduce the amount of water and energy required for dewatering operations. By effectively separating solids from liquids, the panels can help to minimize the volume of water that needs to be treated and disposed of, reducing the environmental impact of mining activities. This can also result in cost savings for mining companies, as less water and energy are required for dewatering operations.

In conclusion, the benefits of using dewatering screen mesh panels in mining operations are numerous and can greatly improve the efficiency and effectiveness of the dewatering process. From their ability to separate solids from liquids to their durability, ease of installation, and environmental friendliness, polyurethane mesh panels are a valuable asset for any mining operation. By investing in dewatering screen mesh panels, mining companies can improve their water management practices, reduce operational costs, and minimize their environmental impact.

In addition to their ability to separate solids from liquids, dewatering screen mesh panels are also highly durable and long-lasting. Polyurethane is a resilient material that can withstand the harsh conditions of mining operations, including high temperatures, abrasive materials, and heavy loads. This durability ensures that the mesh panels will continue to perform effectively over time, reducing the need for frequent replacements and maintenance.

Furthermore, dewatering screen mesh panels are easy to install and maintain, making them a cost-effective solution for mining operations. The panels can be quickly and easily installed on existing dewatering equipment, allowing for minimal downtime and disruption to mining activities. Additionally, the low maintenance requirements of polyurethane mesh panels mean that they can be easily cleaned and maintained, further reducing operational costs.

Another benefit of using dewatering screen mesh panels in mining operations is their versatility. The panels can be customized to meet the specific needs of each mining operation, including different mesh sizes and configurations. This flexibility allows for greater control over the dewatering process, ensuring that the desired level of separation is achieved.

Additionally, dewatering screen mesh panels are environmentally friendly, as they help to reduce the amount of water and energy required for dewatering operations. By effectively separating solids from liquids, the panels can help to minimize the volume of water that needs to be treated and disposed of, reducing the environmental impact of mining activities. This can also result in cost savings for mining companies, as less water and energy are required for dewatering operations.

In conclusion, the benefits of using dewatering screen mesh panels in mining operations are numerous and can greatly improve the efficiency and effectiveness of the dewatering process. From their ability to separate solids from liquids to their durability, ease of installation, and environmental friendliness, polyurethane mesh panels are a valuable asset for any mining operation. By investing in dewatering screen mesh panels, mining companies can improve their water management practices, reduce operational costs, and minimize their environmental impact.

How to Choose the Right Mining polyurethane screen for Improved Efficiency

When it comes to mining operations, efficiency is key. One important component of a successful mining operation is the use of the right equipment, including screens that help to separate materials and ensure that the desired product is obtained. In this article, we will discuss the importance of choosing the right mining polyurethane screen for improved efficiency.polyurethane screens are a popular choice in the mining industry due to their durability, flexibility, and resistance to abrasion. These screens are made from polyurethane material, which is known for its high tensile strength and ability to withstand harsh conditions. Polyurethane screens are also lightweight, making them easy to install and replace when necessary. One important factor to consider when choosing a mining polyurethane screen is the mesh panel size. The mesh panel size refers to the size of the openings in the screen, which determines the size of the particles that can pass through. It is important to choose a mesh panel size that is appropriate for the material being processed. If the mesh panel size is too small, it can lead to clogging and reduced efficiency. On the other hand, if the mesh panel size is too large, it can result in the loss of valuable material. Another important consideration when choosing a mining polyurethane screen is the aperture shape. The aperture shape refers to the shape of the openings in the screen, which can vary from square to rectangular to round. The aperture shape can affect the efficiency of the screening process, as well as the quality of the final product. It is important to choose an aperture shape that is suitable for the material being processed and the desired end product. In addition to mesh panel size and aperture shape, it is also important to consider the tension of the screen. The tension of the screen refers to the amount of force applied to the screen to keep it taut and prevent sagging. Proper tension is essential for efficient screening, as it ensures that the material is properly separated and that the screen is able to withstand the impact of the material being processed. When choosing a mining polyurethane screen, it is also important to consider the type of material being processed. Different materials have different properties, such as size, shape, and density, which can affect the screening process. It is important to choose a screen that is designed to handle the specific characteristics of the material being processed, in order to achieve optimal efficiency. In conclusion, choosing the right mining polyurethane screen is essential for improving efficiency in mining operations. By considering factors such as mesh panel size, aperture shape, tension, and material characteristics, mining companies can ensure that they are using the most suitable screen for their specific needs. Investing in high-quality polyurethane screens can lead to increased productivity, reduced downtime, and improved overall performance in mining operations.