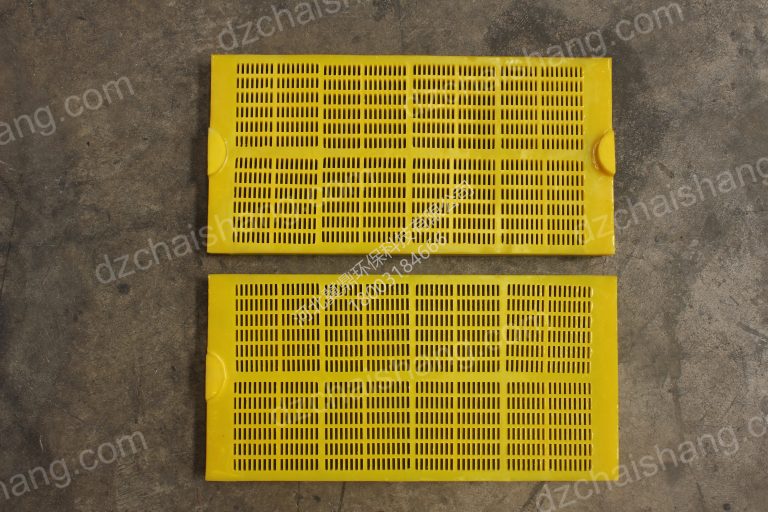

Factory vibrator Rubber tensioned mesh Aggregate

Benefits of Using Factory Vibrator Rubber tensioned mesh in Construction Projects

When it comes to construction projects, ensuring the quality and durability of the materials used is crucial. One material that has gained popularity in recent years is factory vibrator rubber tensioned mesh aggregate. This innovative material offers a range of benefits that make it an ideal choice for a variety of construction applications.

One of the key benefits of using factory vibrator rubber tensioned mesh aggregate is its durability. Made from high-quality rubber materials, this type of mesh is designed to withstand the rigors of construction work. Unlike traditional materials such as steel or concrete, rubber tensioned mesh aggregate is resistant to corrosion, rust, and other forms of degradation. This means that it can last longer and require less maintenance over time, saving both time and money for construction projects.

In addition to its durability, factory vibrator rubber tensioned mesh aggregate also offers excellent flexibility. This material can be easily molded and shaped to fit a variety of construction needs, making it a versatile option for a wide range of projects. Whether you need to create curved surfaces, intricate designs, or custom shapes, rubber tensioned mesh aggregate can be easily manipulated to meet your specific requirements.

Another benefit of using factory vibrator rubber tensioned mesh aggregate is its lightweight nature. Unlike traditional materials that can be heavy and cumbersome to work with, rubber tensioned mesh aggregate is lightweight and easy to handle. This makes it easier for construction workers to transport, maneuver, and install the material, reducing the risk of injury and increasing efficiency on the job site.

Furthermore, factory vibrator rubber tensioned mesh aggregate is also environmentally friendly. Made from recycled rubber materials, this type of mesh helps to reduce waste and minimize the environmental impact of construction projects. By choosing to use rubber tensioned mesh aggregate, construction companies can demonstrate their commitment to sustainability and responsible resource management.

In addition to its durability, flexibility, lightweight nature, and environmental benefits, factory vibrator rubber tensioned mesh aggregate also offers excellent performance characteristics. This material is designed to provide superior shock absorption, noise reduction, and vibration damping properties, making it an ideal choice for projects that require these features. Whether you are working on a building foundation, a road surface, or a sports field, rubber tensioned mesh aggregate can help to improve the overall performance and longevity of the structure.

Overall, factory vibrator rubber tensioned mesh aggregate is a versatile and cost-effective material that offers a range of benefits for construction projects. From its durability and flexibility to its lightweight nature and environmental friendliness, this innovative material is an excellent choice for a variety of applications. By choosing to use rubber tensioned mesh aggregate, construction companies can improve the quality and longevity of their projects while also demonstrating their commitment to sustainability and responsible resource management.

How to Choose the Right Aggregate for Your Construction Needs

When it comes to construction projects, choosing the right aggregate is crucial for ensuring the durability and strength of the finished product. Aggregates are materials such as sand, gravel, or crushed stone that are mixed with cement and water to create concrete. They provide bulk and stability to the concrete mix, making it suitable for various construction applications.

One important factor to consider when selecting an aggregate is the size and shape of the particles. The size of the aggregate particles can affect the workability and strength of the concrete mix. Larger particles provide more strength, while smaller particles improve workability. The shape of the particles also plays a role in the overall strength and durability of the concrete. Angular particles interlock better than rounded particles, providing a stronger bond within the mix.

Another crucial consideration when choosing an aggregate is the gradation or distribution of particle sizes. A well-graded aggregate mix contains a variety of particle sizes, from fine to coarse. This ensures that the concrete mix is compacted properly and has good workability. On the other hand, a poorly graded mix can lead to segregation and a weaker finished product.

In addition to size and gradation, the quality of the aggregate is also essential. High-quality aggregates are free from impurities such as clay, silt, or organic matter, which can weaken the concrete mix. It is important to source aggregates from reputable suppliers who can provide consistent quality and ensure that the materials meet industry standards.

One common type of aggregate used in construction is crushed stone. This material is produced by crushing large rocks into smaller pieces and is commonly used in road construction, drainage systems, and as a base material for buildings. Crushed stone aggregates are available in various sizes and can be used for different applications depending on the project requirements.

Another popular aggregate option is sand. Sand is a fine aggregate that is often used in concrete mixes to improve workability and reduce shrinkage. It is also commonly used in mortar mixes for bricklaying and plastering. The quality of sand is crucial, as impurities can affect the strength and durability of the finished product.

Gravel is another commonly used aggregate in construction projects. It is a coarse aggregate that is typically used in concrete mixes for structural applications such as foundations, driveways, and sidewalks. Gravel aggregates are available in various sizes and can provide good drainage and stability to the concrete mix.

In addition to natural aggregates, recycled aggregates are also becoming more popular in construction. These materials are produced from recycled concrete, asphalt, or other construction waste and can be used as a sustainable alternative to traditional aggregates. Recycled aggregates can help reduce the environmental impact of construction projects and conserve natural resources.

In conclusion, choosing the right aggregate is essential for the success of any construction project. Factors such as particle size, shape, gradation, and quality all play a role in determining the strength and durability of the finished product. By selecting high-quality aggregates that meet industry standards and project requirements, construction professionals can ensure that their projects are built to last.