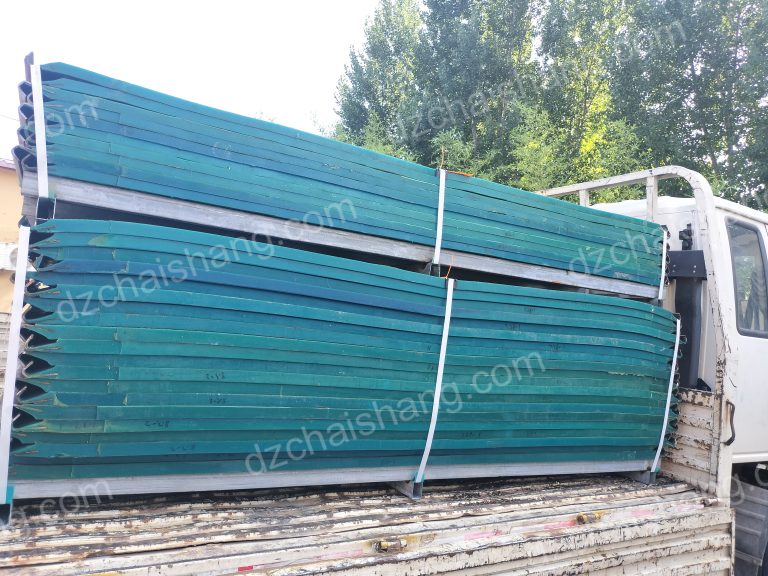

factory Rubber tension sieve Ore,outright sale vibrating Rubber flip flop plate

Maximizing Efficiency: How to Optimize Rubber Tension Sieve Operations in Your Factory Rubber tension sieve ore, outright sale vibrating rubber flip flop…

Maximizing Efficiency: How to Optimize Rubber Tension Sieve Operations in Your Factory

Rubber tension sieve ore, outright sale vibrating rubber flip flop plate systems play a crucial role in various industries, ensuring efficient separation of materials of different sizes. However, maximizing efficiency in their operations requires careful planning, maintenance, and optimization strategies. By implementing the right practices, factories can enhance productivity, reduce downtime, and ultimately improve their bottom line. To begin with, it’s essential to understand the fundamental principles behind rubber tension sieve operations. These systems utilize rubber screens with tensioned wires to effectively sieve materials based on size. The vibrating motion aids in the separation process, ensuring that particles are sorted according to their dimensions. Understanding these principles forms the basis for optimizing operations. Regular maintenance is paramount in ensuring the smooth functioning of rubber tension sieve systems. This includes inspecting and replacing worn-out components such as tensioned wires and rubber panels. Routine lubrication of bearings and other moving parts also prevents frictional wear and tear, prolonging the lifespan of the equipment. By adhering to a proactive maintenance schedule, factories can minimize unexpected breakdowns and maintain consistent productivity levels.

Calibration is another crucial aspect of optimizing rubber tension sieve operations. Ensuring that the equipment is properly calibrated according to the specific requirements of the materials being processed is essential for achieving accurate separation. This may involve adjusting parameters such as vibration intensity and screen inclination to achieve optimal results. Regular calibration checks help maintain efficiency and prevent deviations that could lead to subpar performance.

In addition to maintenance and calibration, implementing efficient material handling practices can further enhance productivity. Proper feeding of materials onto the sieve ensures uniform distribution and prevents overloading, which can strain the equipment and affect performance. Employing technologies such as feeders and conveyors can streamline the material handling process, reducing manual intervention and minimizing the risk of operational errors.

Furthermore, investing in advanced monitoring and control systems can provide real-time insights into the performance of rubber tension sieve operations. These systems can detect abnormalities such as uneven wear or excessive vibration, allowing for prompt intervention before issues escalate. By leveraging data analytics and predictive maintenance algorithms, factories can optimize performance, minimize downtime, and maximize throughput.

Training and education also play a vital role in optimizing rubber tension sieve operations. Providing comprehensive training to operators ensures that they are equipped with the knowledge and skills to operate the equipment effectively. This includes proper startup and shutdown procedures, troubleshooting common issues, and implementing best practices for maintenance and calibration. Continuous education programs keep operators updated on the latest advancements in sieve technology, enabling them to adapt to changing operational requirements.

In conclusion, maximizing efficiency in rubber tension sieve operations requires a holistic approach encompassing maintenance, calibration, material handling, monitoring, and training. By implementing proactive maintenance practices, optimizing calibration settings, improving material handling processes, investing in monitoring systems, and providing comprehensive training, factories can enhance productivity and profitability. Ultimately, these efforts contribute to the overall success of the operation, ensuring consistent performance and competitive advantage in the market.

Regular maintenance is paramount in ensuring the smooth functioning of rubber tension sieve systems. This includes inspecting and replacing worn-out components such as tensioned wires and rubber panels. Routine lubrication of bearings and other moving parts also prevents frictional wear and tear, prolonging the lifespan of the equipment. By adhering to a proactive maintenance schedule, factories can minimize unexpected breakdowns and maintain consistent productivity levels.

Calibration is another crucial aspect of optimizing rubber tension sieve operations. Ensuring that the equipment is properly calibrated according to the specific requirements of the materials being processed is essential for achieving accurate separation. This may involve adjusting parameters such as vibration intensity and screen inclination to achieve optimal results. Regular calibration checks help maintain efficiency and prevent deviations that could lead to subpar performance.

In addition to maintenance and calibration, implementing efficient material handling practices can further enhance productivity. Proper feeding of materials onto the sieve ensures uniform distribution and prevents overloading, which can strain the equipment and affect performance. Employing technologies such as feeders and conveyors can streamline the material handling process, reducing manual intervention and minimizing the risk of operational errors.

Furthermore, investing in advanced monitoring and control systems can provide real-time insights into the performance of rubber tension sieve operations. These systems can detect abnormalities such as uneven wear or excessive vibration, allowing for prompt intervention before issues escalate. By leveraging data analytics and predictive maintenance algorithms, factories can optimize performance, minimize downtime, and maximize throughput.

Training and education also play a vital role in optimizing rubber tension sieve operations. Providing comprehensive training to operators ensures that they are equipped with the knowledge and skills to operate the equipment effectively. This includes proper startup and shutdown procedures, troubleshooting common issues, and implementing best practices for maintenance and calibration. Continuous education programs keep operators updated on the latest advancements in sieve technology, enabling them to adapt to changing operational requirements.

In conclusion, maximizing efficiency in rubber tension sieve operations requires a holistic approach encompassing maintenance, calibration, material handling, monitoring, and training. By implementing proactive maintenance practices, optimizing calibration settings, improving material handling processes, investing in monitoring systems, and providing comprehensive training, factories can enhance productivity and profitability. Ultimately, these efforts contribute to the overall success of the operation, ensuring consistent performance and competitive advantage in the market.