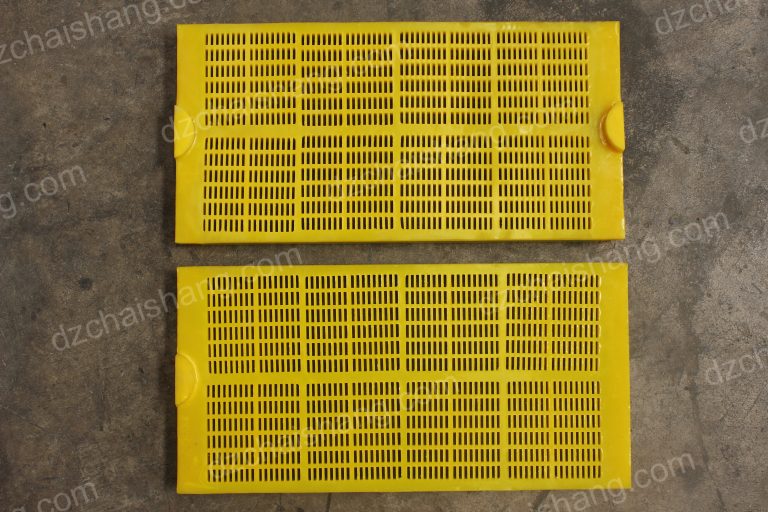

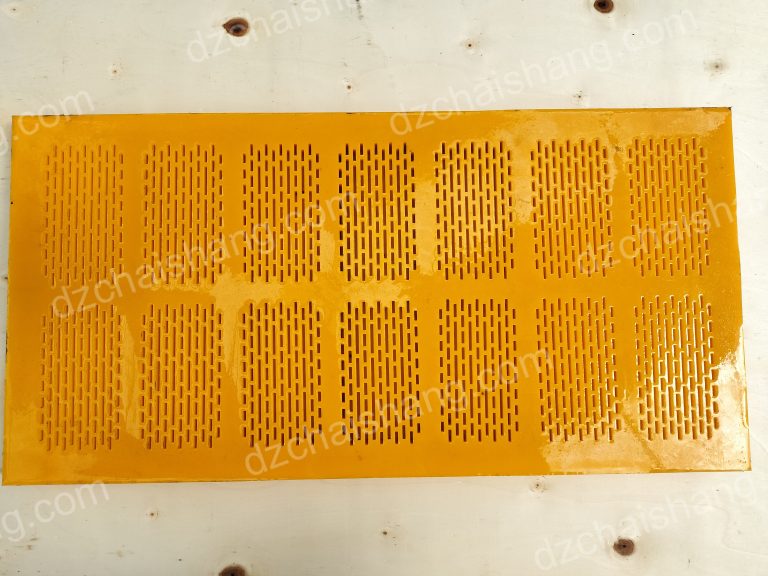

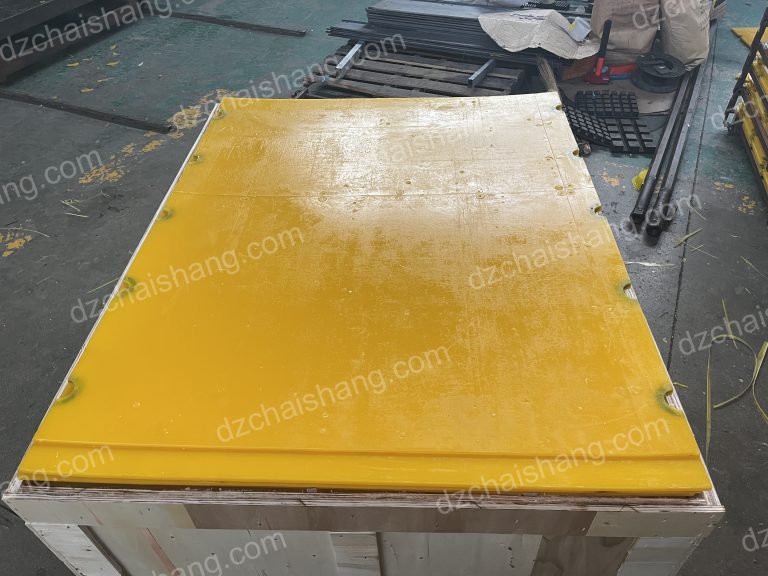

Factory Polyurethane tensioned Media Ore,outright sale shaker tensioned PU panel

Advantages of Using Factory polyurethane Tensioned Media Ore in Shaker screens Factory polyurethane tensioned media ore, also known as shaker tensioned PU…

Advantages of Using Factory polyurethane Tensioned Media Ore in Shaker screens

Factory polyurethane tensioned media ore, also known as shaker tensioned PU panels, are becoming increasingly popular in various industries due to their numerous advantages. These panels are utilized in shaker screens, which are essential equipment in the screening process for various materials, including ores, aggregates, and industrial minerals. One of the primary advantages of using factory polyurethane tensioned media ore in shaker screens is their exceptional durability. Unlike traditional wire mesh screens, Polyurethane Panels are highly resistant to wear, abrasion, and corrosion. This durability ensures prolonged screen life, reducing the frequency of replacements and maintenance downtime. Furthermore, factory polyurethane tensioned media ore offers superior screening efficiency. The precise design and construction of these panels result in consistent and accurate particle separation, leading to higher throughput and improved product quality. This efficiency is especially crucial in industries where precise particle size distribution is essential for downstream processes. In addition to durability and efficiency, factory polyurethane tensioned media ore provides significant cost savings over time. While the initial investment may be higher compared to traditional screens, the long-term benefits outweigh the upfront costs. Reduced maintenance, fewer replacements, and increased productivity result in lower overall operational expenses, making polyurethane panels a cost-effective solution in the long run. Moreover, factory polyurethane tensioned media ore offers versatility in application. These panels can be customized to meet specific screening requirements, including aperture size, panel dimensions, and surface characteristics. Whether screening fine particles or heavy aggregates, polyurethane panels can be tailored to optimize performance and maximize productivity. Another advantage of using factory polyurethane tensioned media ore is their environmental sustainability. Unlike wire mesh screens, which can generate waste and require frequent disposal, polyurethane panels are recyclable and contribute to a more sustainable production process. By minimizing waste generation and promoting recycling, industries can reduce their environmental footprint and adhere to sustainability goals. Furthermore, factory polyurethane tensioned media ore is easy to install and maintain, minimizing downtime and maximizing uptime. These panels can be quickly replaced or repaired, ensuring continuous operation and uninterrupted production. Additionally, their lightweight construction reduces strain on shaker equipment, prolonging its lifespan and minimizing maintenance costs. In summary, factory polyurethane tensioned media ore offers numerous advantages for shaker screens in various industries. From exceptional durability and screening efficiency to cost savings and environmental sustainability, polyurethane panels provide a reliable and efficient solution for particle separation applications. With their versatility, ease of installation, and low maintenance requirements, polyurethane panels are increasingly preferred by industries seeking to optimize their screening processes and enhance overall productivity.

In summary, factory polyurethane tensioned media ore offers numerous advantages for shaker screens in various industries. From exceptional durability and screening efficiency to cost savings and environmental sustainability, polyurethane panels provide a reliable and efficient solution for particle separation applications. With their versatility, ease of installation, and low maintenance requirements, polyurethane panels are increasingly preferred by industries seeking to optimize their screening processes and enhance overall productivity.