صفحه نمایش ویبره، صفحه غربال ویبره، صفحه نمایش پلی اورتان

درک عملکرد و کاربردهای صفحه نمایش لرزان صفحه نمایش ویبره که به عنوان صفحه غربال ارتعاشی یا صفحه نمایش پلی یورتان نیز…

درک عملکرد و کاربردهای صفحه نمایش لرزان

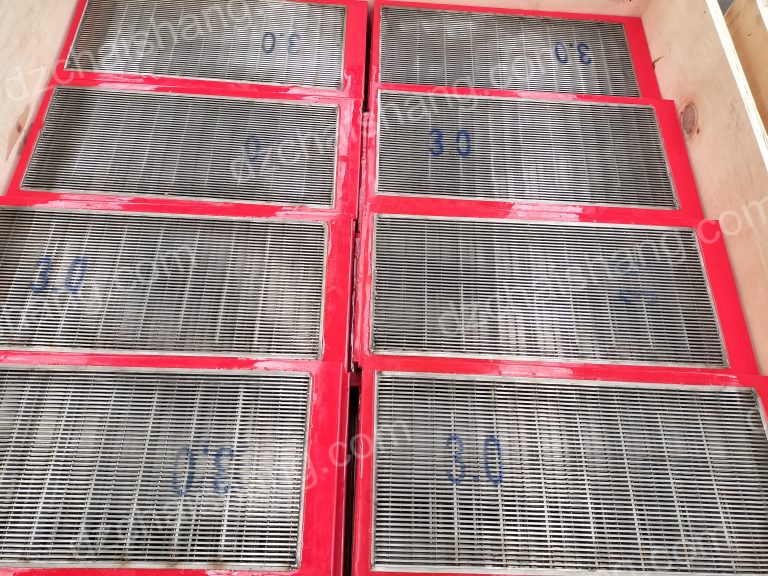

صفحه نمایش ویبره که به عنوان صفحه غربال ارتعاشی یا صفحه نمایش پلی یورتان نیز شناخته می شود، از تجهیزات ضروری در صنایع مختلف، به ویژه در بخش معدن و فرآوری مواد معدنی است. این دستگاهها نقش مهمی در جداسازی و طبقهبندی مواد ایفا میکنند و کسبوکارها را قادر میسازند تا عملیات خود را ساده کرده و بهرهوری را افزایش دهند. هدف این مقاله ارائه یک درک جامع از عملکرد و کاربردهای صفحه نمایش ارتعاشی است. صفحه نمایش شامل مجموعهای از صفحهها یا مشها با اندازههای مختلف است که مستقل از یکدیگر میلرزند. ارتعاش باعث می شود که ذرات در سراسر صفحه حرکت کنند و بر اساس اندازه آنها به لایه های مختلف جدا شوند. ذرات بزرگتر در بالا باقی می مانند، در حالی که ذرات کوچکتر از شبکه ها عبور می کنند و به طور جداگانه جمع آوری می شوند. این فرآیند به عنوان طبقه بندی شناخته می شود.

عملکرد اصلی یک صفحه ارتعاشی جداسازی و درجه بندی مواد بر اساس اندازه است. با این حال، آنها همچنین می توانند برای آبگیری، آبگیری و بازیابی متوسط استفاده شوند. به عنوان مثال، در صنعت معدن، از صفحات ارتعاشی برای جداسازی و بازیابی مواد معدنی با ارزش از سنگ معدن خرد شده استفاده می شود. در صنایع غذایی از آنها برای جداسازی اندازه های مختلف ذرات غذا استفاده می شود. در صنعت ساختمان از آنها برای جداسازی و درجه بندی اندازه های مختلف ماسه، شن و سنگ خرد شده استفاده می شود.

مزایای صفحه های پلی اورتان نسبت به صفحات غربالی سنتی

The Advantages of polyurethane screens over Traditional Sieve Screens

Vibrating screens, also known as vibrating sieve screens, are essential tools in various industries as they help to separate and filter different sized materials. These screens have evolved over the years, with the latest innovation being the polyurethane screen. This article will delve into the advantages of polyurethane screens over traditional sieve screens.

Polyurethane screens have gained popularity due to their durability and efficiency. Unlike traditional sieve screens made from metal or wire mesh, polyurethane screens are made from a flexible material that can withstand high levels of strain without tearing or breaking. This makes them ideal for heavy-duty applications such as mining and quarrying, where screens are subjected to intense pressure and wear. Consequently, polyurethane screens have a longer lifespan, reducing the need for frequent replacements and thus lowering operational costs.

In addition to their durability, polyurethane screens offer superior performance. They have a higher screening efficiency due to their flexibility, which allows them to vibrate and move with the material being screened. This movement increases the chances of smaller particles passing through the screen, resulting in a more refined and accurate separation. Furthermore, polyurethane screens have a lower noise level compared to metal screens. The soft nature of polyurethane absorbs the vibration, reducing the noise produced during the screening process. This feature not only creates a more conducive working environment but also complies with noise regulation standards in many industries.

Another significant advantage of polyurethane screens is their resistance to environmental conditions. Traditional sieve screens, especially those made from metal, are prone to rust and corrosion when exposed to moisture and certain chemicals. On the other hand, polyurethane is a synthetic material that is resistant to water, oil, and most chemicals. This resistance ensures that the screens maintain their structural integrity and performance even in harsh conditions, further enhancing their durability and lifespan.

Polyurethane screens also offer the advantage of customization. They can be manufactured in a wide range of sizes, shapes, and configurations to suit different applications. This flexibility allows for the design of screens with specific characteristics such as varying hole sizes for precise screening or different panel sizes for easy installation and replacement. Moreover, polyurethane screens can be produced in various colors, which can be used to differentiate screens based on their application or to match the aesthetic requirements of a particular setting.

Lastly, the use of polyurethane screens contributes to environmental sustainability. The long lifespan of these screens means less frequent replacements, leading to reduced waste. Additionally, polyurethane is a recyclable material. At the end of their useful life, these screens can be recycled into other useful products, reducing the environmental impact.

In conclusion, polyurethane screens offer numerous advantages over traditional sieve screens. Their durability, high performance, resistance to environmental conditions, customization options, and contribution to environmental sustainability make them a superior choice in various industries. As technology continues to advance, it is expected that the use of polyurethane screens will become even more widespread, further revolutionizing the screening process.