trommel mesh,high frequency screen panel,high frequency screen

Exploring the Efficiency of Trommel mesh, high frequency screen Panel, and High Frequency Screen in Material Separation The world of material separation…

Exploring the Efficiency of Trommel mesh, high frequency screen Panel, and High Frequency Screen in Material Separation

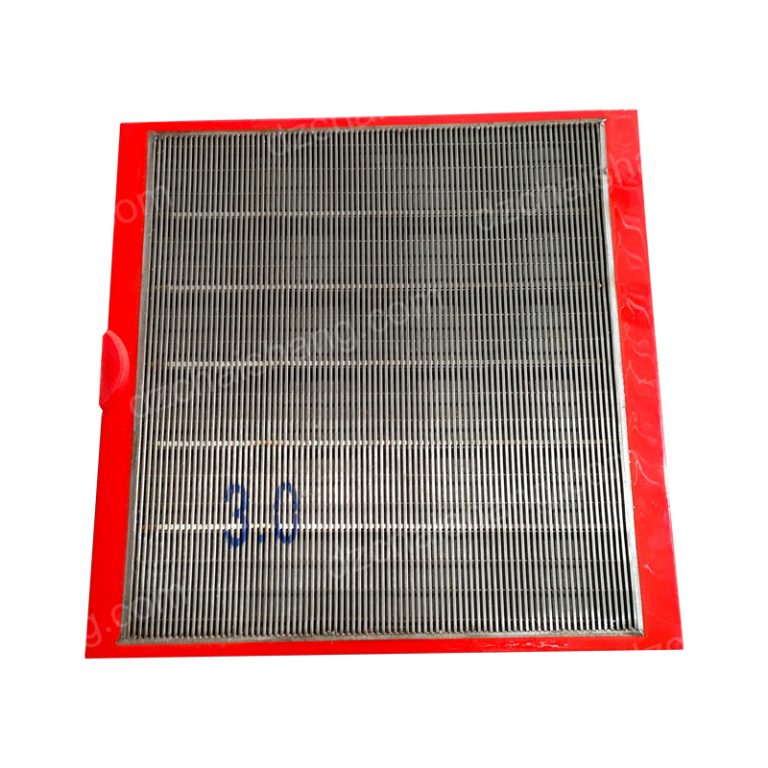

The world of material separation is a complex one, with a variety of tools and technologies at our disposal. Among these, the trommel mesh, high frequency screen panel, and high frequency screen stand out for their efficiency and effectiveness. These tools are used in a variety of industries, including mining, construction, and waste management, to separate and sort materials of different sizes and types. The trommel mesh is a cylindrical drum that is usually motor-driven and used for separating materials based on their size. The drum is fitted with a mesh screen that allows smaller materials to fall through while larger ones are carried to the end of the drum for disposal or further processing. The size of the mesh can be adjusted depending on the specific requirements of the task at hand, making the trommel mesh a versatile tool in material separation. Its efficiency lies in its simplicity and adaptability, allowing it to be used in a wide range of applications.

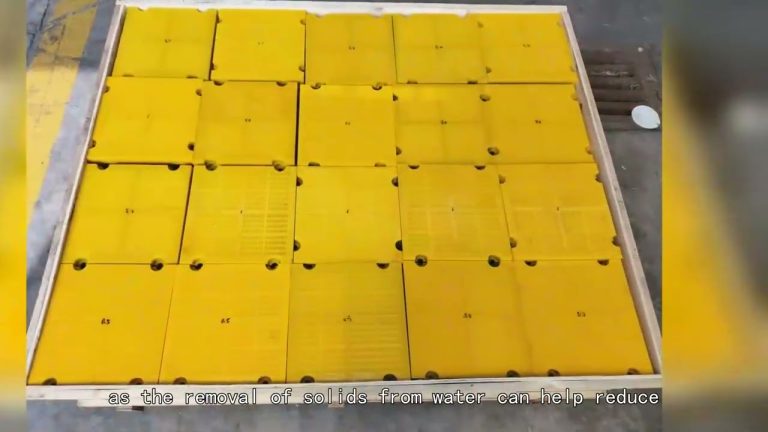

On the other hand, the high frequency screen panel operates on a different principle. It uses vibration to separate materials based on their size and density. The screen panel is set to vibrate at a high frequency, causing the materials on it to move in different directions depending on their size and weight. This results in a highly efficient separation process that can handle large volumes of material in a short amount of time. The high frequency screen panel is particularly useful in industries where speed and efficiency are of the essence, such as in mining operations.