polyurethane mining screens,polyurethane modular screens

The Advantages of polyurethane mining screens in Modern Mining Operations In the realm of modern mining operations, the quest for efficiency and…

The Advantages of polyurethane mining screens in Modern Mining Operations

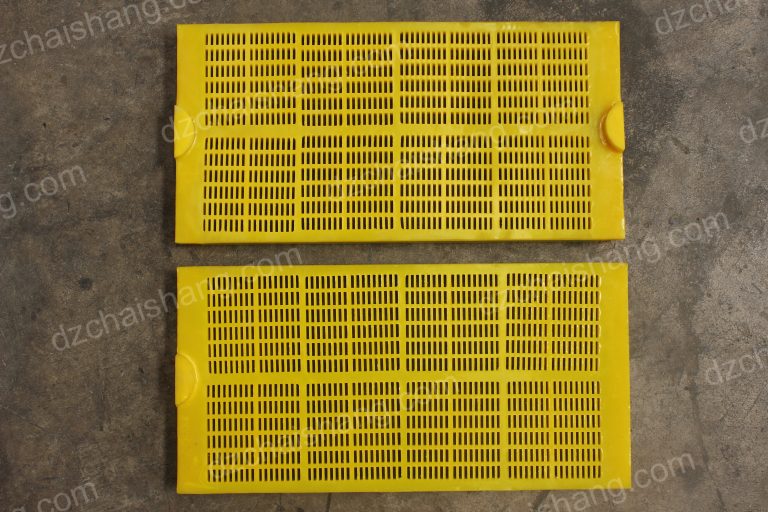

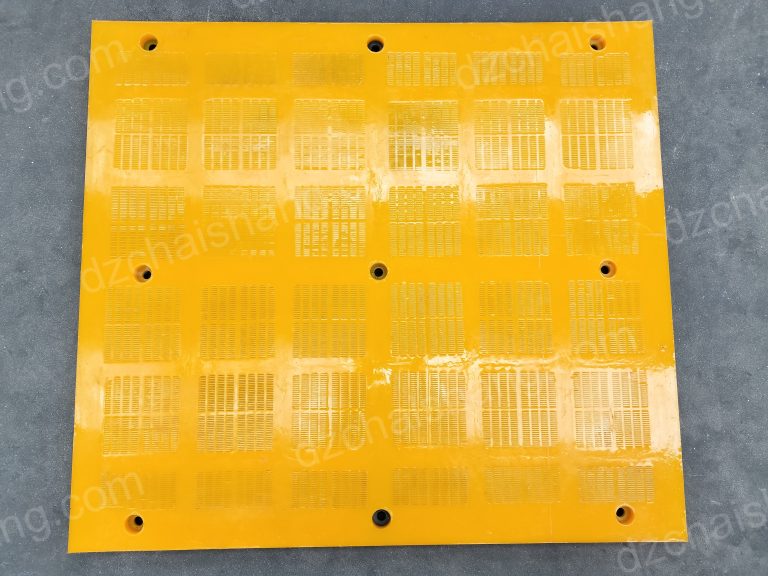

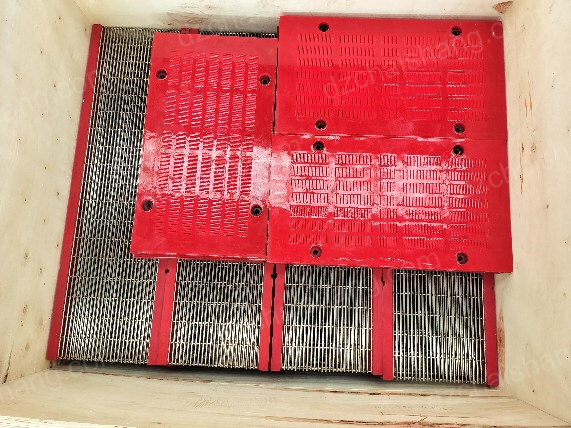

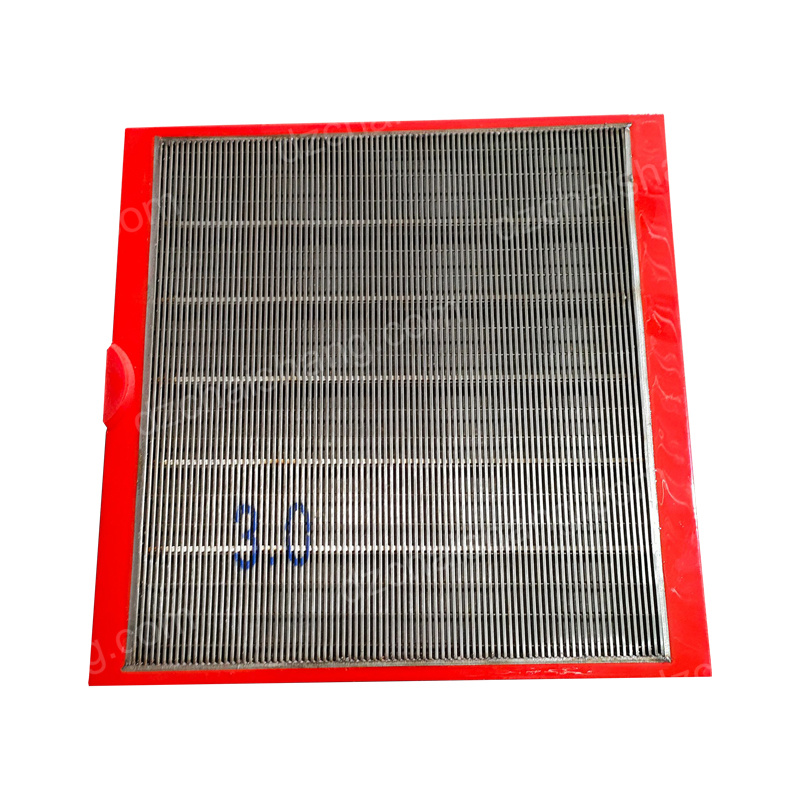

In the realm of modern mining operations, the quest for efficiency and durability in materials handling and processing has led to significant advancements in technology and materials. Among these, polyurethane mining screens and modular screens have emerged as pivotal components, offering a plethora of advantages over traditional screening materials like wire mesh and steel. This article delves into the myriad benefits that polyurethane screens bring to the table, underscoring their importance in enhancing the productivity and sustainability of mining operations. Polyurethane, a versatile polymer composed of organic units joined by carbamate links, is renowned for its exceptional properties, including high abrasion resistance, flexibility, and the ability to withstand extreme conditions. These characteristics make polyurethane mining screens highly suitable for the demanding environment of mining operations, where they are subjected to continuous vibration, impact, and wear. Unlike their metal counterparts, which can corrode and wear down quickly, polyurethane screens offer a longer service life, significantly reducing the need for frequent replacements and, consequently, lowering operational costs. Moreover, the flexibility of polyurethane is a critical advantage in screening applications. This flexibility allows the screens to absorb impact more effectively than rigid materials, reducing the likelihood of breakage and ensuring consistent performance. Additionally, polyurethane screens can be manufactured with varying degrees of hardness, tailored to specific mining applications, further enhancing their efficiency and wear life. Another significant benefit of polyurethane mining screens is their superior screening efficiency. Designed with precision openings and a smooth surface, these screens minimize the chances of blinding and pegging—common issues with wire mesh screens where particles get lodged in the openings or stuck on the surface. This ensures a more consistent material flow and higher quality screening, enabling miners to process materials more quickly and accurately. The improved screening efficiency not only boosts productivity but also contributes to energy savings, as less power is required to process the same amount of material. polyurethane modular screens add another layer of versatility and convenience to mining operations. These screens are composed of individual modules that can be easily replaced or rearranged, allowing for quick repairs and adjustments to the screening configuration without the need to replace the entire screen. This modularity is particularly beneficial in adapting to varying mining conditions and materials, ensuring that the screening process remains optimal over time. Furthermore, the ease of maintenance and replacement associated with modular designs reduces downtime, keeping operations running smoothly and efficiently. Environmental considerations are increasingly becoming a priority in mining operations, and here too, polyurethane screens offer advantages. Their durability and longer lifespan mean that less waste is generated from worn-out screens, contributing to more sustainable mining practices. Additionally, the energy savings from improved screening efficiency further reduce the environmental footprint of mining activities. In conclusion, the adoption of polyurethane mining screens and modular screens represents a significant advancement in mining technology. Their superior durability, flexibility, screening efficiency, and environmental benefits make them an indispensable tool in the modern miner’s arsenal. As mining operations continue to evolve and seek more efficient and sustainable practices, the role of polyurethane screens is set to become even more central, underscoring their importance in the future of mining.Maintenance and Durability: A Comparative Analysis of Polyurethane Modular Screens

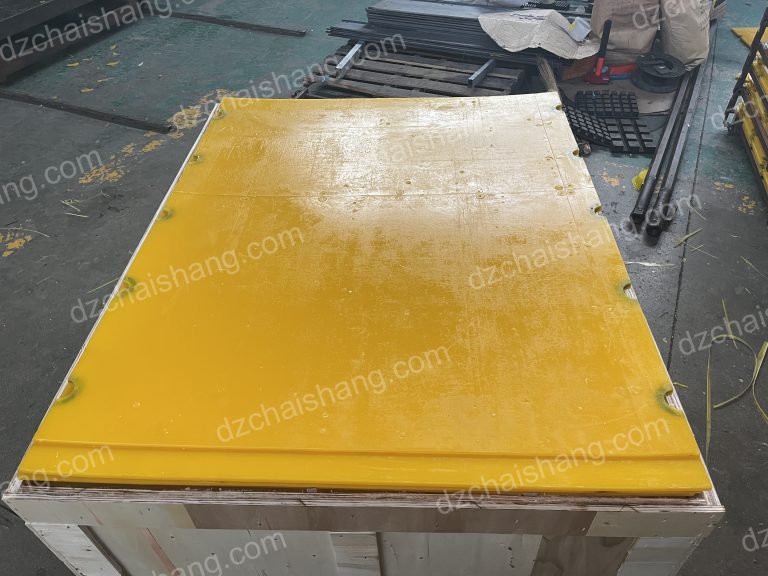

Polyurethane mining screens and polyurethane modular screens have become increasingly popular in the mining industry due to their exceptional durability and maintenance advantages over traditional screening materials like wire mesh and steel. As the demand for more efficient and cost-effective mining operations grows, the importance of using materials that can withstand the harsh mining environment while providing consistent performance cannot be overstated. In this comparative analysis, we will delve into the maintenance and durability aspects of polyurethane modular screens, highlighting why they are considered a superior choice for mining applications. Polyurethane, a versatile polymer composed of organic units joined by carbamate links, is known for its exceptional abrasion resistance and ability to absorb impact. These properties make it an ideal material for mining screens, which are subject to continuous wear and tear from abrasive materials and mechanical stress. Unlike wire mesh screens that can quickly become compromised when exposed to sharp or heavy objects, polyurethane screens maintain their integrity, significantly reducing the frequency of screen replacements. This inherent toughness translates to longer service life and reduced downtime for maintenance, which is critical in mining operations where every minute of halted production can lead to substantial financial losses. Moreover, the flexibility of polyurethane modular screens is a key factor in their durability. They are able to flex and return to their original shape, which helps in releasing entrapped materials that could otherwise cause blinding or pegging in more rigid screens. This self-cleaning property not only improves the efficiency of the screening process but also minimizes the need for manual cleaning and maintenance, further enhancing the operational uptime.Another advantage of polyurethane screens is their resistance to environmental factors such as corrosion, moisture, and temperature variations. In contrast to steel screens that can rust and degrade over time, especially in wet or humid conditions, polyurethane screens are impervious to such elements, ensuring consistent performance and longevity. This resistance to corrosion also means that polyurethane screens are less likely to contaminate the screened materials with rust particles, which is particularly important in applications where material purity is paramount. The modular design of polyurethane screens offers additional maintenance benefits. Individual panels or modules can be easily replaced without the need to change the entire screen, making repairs quick and cost-effective. This modularity also allows for customized configurations to meet specific screening requirements, enhancing the overall efficiency of the operation. Furthermore, the lightweight nature of polyurethane screens compared to their metal counterparts facilitates easier handling and installation. This not only reduces the risk of injury during maintenance tasks but also lowers the labor costs associated with screen replacements and repairs.

In conclusion, polyurethane modular screens represent a significant advancement in mining technology, offering superior durability and reduced maintenance requirements. Their ability to withstand abrasive materials, resist environmental degradation, and facilitate easy repairs makes them an invaluable asset in the mining industry. As operations continue to seek ways to improve efficiency and reduce costs, the adoption of polyurethane screens is likely to become even more widespread, solidifying their status as a key component in the future of mining.

In conclusion, polyurethane modular screens represent a significant advancement in mining technology, offering superior durability and reduced maintenance requirements. Their ability to withstand abrasive materials, resist environmental degradation, and facilitate easy repairs makes them an invaluable asset in the mining industry. As operations continue to seek ways to improve efficiency and reduce costs, the adoption of polyurethane screens is likely to become even more widespread, solidifying their status as a key component in the future of mining.