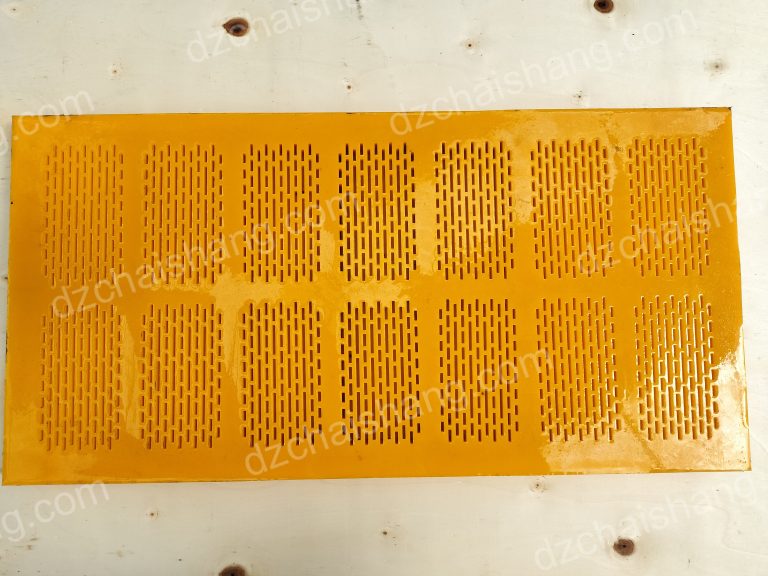

Ore PU flexible modular polyurethane sieving plate

Benefits of Using Ore PU Flexible Modular polyurethane Sieving Plate Ore PU flexible modular polyurethane sieving plates are a versatile and durable…

Benefits of Using Ore PU Flexible Modular polyurethane Sieving Plate

Ore PU flexible modular polyurethane sieving plates are a versatile and durable solution for a wide range of screening applications. These innovative sieving plates are designed to provide superior performance and efficiency compared to traditional metal or rubber screens. In this article, we will explore the benefits of using ore PU flexible modular polyurethane sieving plates in various industries. One of the key advantages of ore PU flexible modular polyurethane sieving plates is their flexibility. These sieving plates can be easily customized to fit any screening application, making them ideal for a wide range of industries. Whether you are screening aggregates, minerals, or other materials, ore PU flexible modular polyurethane sieving plates can be tailored to meet your specific needs.

In addition to their flexibility, ore PU flexible modular polyurethane sieving plates are also highly durable. Unlike traditional metal screens, which can corrode and wear out over time, polyurethane sieving plates are resistant to abrasion and corrosion. This means that they can withstand the harsh conditions of screening operations without losing their effectiveness.

Furthermore, ore PU flexible modular polyurethane sieving plates are designed to provide superior screening performance. The unique design of these sieving plates allows for efficient material separation, resulting in higher throughput and reduced downtime. This can lead to increased productivity and cost savings for your operation.

Another benefit of using ore PU flexible modular polyurethane sieving plates is their ease of installation and maintenance. These sieving plates can be quickly and easily installed on existing screening equipment, minimizing downtime and reducing labor costs. Additionally, polyurethane sieving plates are easy to clean and maintain, ensuring optimal performance over the long term.

In addition to their performance and durability, ore PU flexible modular polyurethane sieving plates are also environmentally friendly. Polyurethane is a recyclable material, making it a sustainable choice for screening applications. By choosing ore PU flexible modular polyurethane sieving plates, you can reduce your environmental impact and contribute to a more sustainable future.

Overall, ore PU flexible modular polyurethane sieving plates offer a range of benefits for a variety of industries. From their flexibility and durability to their superior performance and ease of installation, these sieving plates are a cost-effective and efficient solution for all your screening needs. Whether you are in the mining, aggregates, or recycling industry, ore PU flexible modular polyurethane sieving plates can help you achieve optimal results and maximize your productivity. Consider incorporating these innovative sieving plates into your screening operations to experience the many benefits they have to offer.

One of the key advantages of ore PU flexible modular polyurethane sieving plates is their flexibility. These sieving plates can be easily customized to fit any screening application, making them ideal for a wide range of industries. Whether you are screening aggregates, minerals, or other materials, ore PU flexible modular polyurethane sieving plates can be tailored to meet your specific needs.

In addition to their flexibility, ore PU flexible modular polyurethane sieving plates are also highly durable. Unlike traditional metal screens, which can corrode and wear out over time, polyurethane sieving plates are resistant to abrasion and corrosion. This means that they can withstand the harsh conditions of screening operations without losing their effectiveness.

Furthermore, ore PU flexible modular polyurethane sieving plates are designed to provide superior screening performance. The unique design of these sieving plates allows for efficient material separation, resulting in higher throughput and reduced downtime. This can lead to increased productivity and cost savings for your operation.

Another benefit of using ore PU flexible modular polyurethane sieving plates is their ease of installation and maintenance. These sieving plates can be quickly and easily installed on existing screening equipment, minimizing downtime and reducing labor costs. Additionally, polyurethane sieving plates are easy to clean and maintain, ensuring optimal performance over the long term.

In addition to their performance and durability, ore PU flexible modular polyurethane sieving plates are also environmentally friendly. Polyurethane is a recyclable material, making it a sustainable choice for screening applications. By choosing ore PU flexible modular polyurethane sieving plates, you can reduce your environmental impact and contribute to a more sustainable future.

Overall, ore PU flexible modular polyurethane sieving plates offer a range of benefits for a variety of industries. From their flexibility and durability to their superior performance and ease of installation, these sieving plates are a cost-effective and efficient solution for all your screening needs. Whether you are in the mining, aggregates, or recycling industry, ore PU flexible modular polyurethane sieving plates can help you achieve optimal results and maximize your productivity. Consider incorporating these innovative sieving plates into your screening operations to experience the many benefits they have to offer.