what is the best screen mesh,very fine screen mesh

The Ultimate Guide to Choosing the Best screen mesh for Your Needs Title: The Ultimate Guide to Choosing the Best Screen Mesh…

The Ultimate Guide to Choosing the Best screen mesh for Your Needs

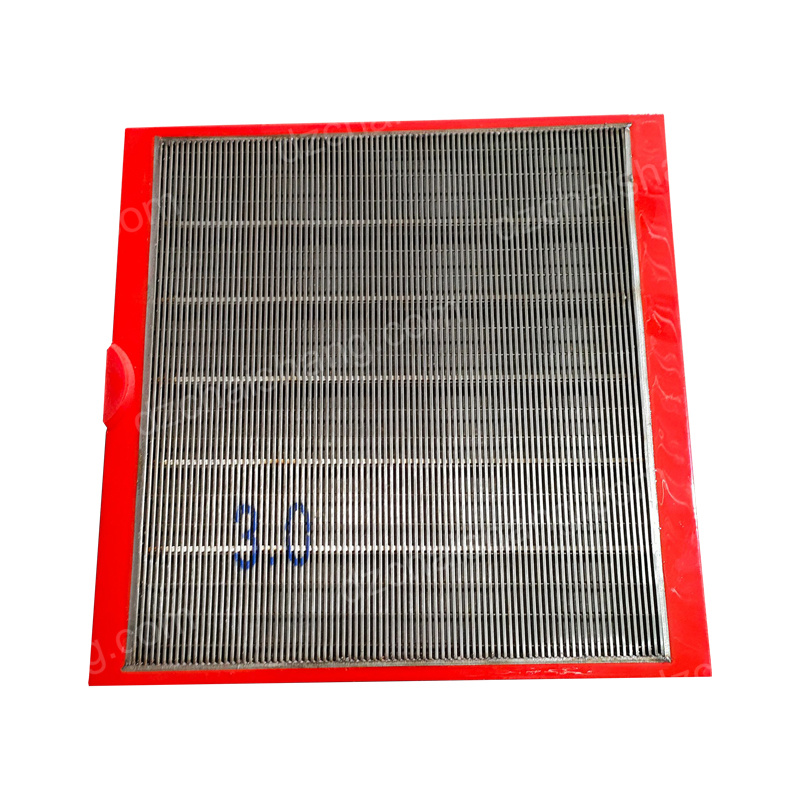

Title: The Ultimate Guide to Choosing the Best Screen Mesh for Your Needs In the world of industrial, commercial, and residential applications, the selection of the appropriate screen mesh is a critical decision that can significantly impact the efficiency and outcome of various processes. Screen mesh, a woven material typically made from metal, plastic, or synthetic fibers, is used for a multitude of purposes, from filtering and sieving to providing security and ventilation. When it comes to determining the best screen mesh, particularly when a very fine screen mesh is required, several factors must be taken into account to ensure optimal performance and longevity. The term “very fine screen mesh” refers to screens with a high number of openings per inch (OPI) or a small aperture size. These screens are adept at filtering out minute particles and are essential in industries where precision is paramount, such as in pharmaceutical manufacturing, food and beverage production, and in scientific research. The fineness of a screen mesh is measured in microns, which denotes the size of the openings. The smaller the micron rating, the finer the mesh. Material selection is the cornerstone of choosing the best screen mesh. Stainless steel is a popular choice for very fine screen meshes due to its durability and resistance to corrosion. It is suitable for use in harsh environments and where exposure to chemicals or extreme temperatures is a concern. For applications that require flexibility and lighter weight, synthetic materials like polyester or nylon may be more appropriate. These materials also offer excellent resistance to abrasion and can be used in processes involving water or other liquids. The weave of the mesh is another critical aspect to consider. The plain weave, which is the most common and features a simple over-and-under pattern, provides a uniform and consistent opening size, making it ideal for precise filtration. Twill weave, on the other hand, allows for the use of thicker wires and thus is used when strength is a priority. The Dutch weave, characterized by a tight and dense pattern, is particularly suited for very fine filtration applications. The wire diameter in a screen mesh affects both its strength and its open area. A finer wire will result in a higher open area, which increases the screen’s throughput, but may reduce its strength and durability. Conversely, a thicker wire will provide more strength but reduce the open area, potentially limiting the flow of material through the mesh. Therefore, it is crucial to strike a balance between the wire diameter and the open area to meet the specific needs of the application. In addition to the material, weave, and wire diameter, the end-use of the screen mesh must be considered. For instance, in the case of insect screening for residential use, a very fine mesh is necessary to prevent the smallest of insects from entering while still allowing for airflow and visibility. In industrial settings, the screen mesh must withstand mechanical stresses and possibly abrasive materials, necessitating a robust construction. Ultimately, the best screen mesh is one that aligns with the specific requirements of the task at hand. It should provide the necessary level of filtration, withstand the operational environment, and offer the durability to maintain its integrity over time. Whether the application demands a very fine screen mesh for intricate filtering or a more robust mesh for heavy-duty use, careful consideration of the factors outlined above will guide users to the most suitable selection. In conclusion, choosing the best screen mesh, especially a very fine one, is a nuanced process that involves understanding the interplay between material properties, weave patterns, and the intended application. By meticulously evaluating these elements, one can ensure that the chosen screen mesh not only meets but exceeds the expectations of its intended use, providing efficiency and reliability in any context.Exploring the Benefits of Very Fine Screen Mesh for Superior Filtration and Protection

Exploring the Benefits of Very Fine Screen Mesh for Superior Filtration and Protection

In conclusion, very fine screen mesh is a highly effective solution for superior filtration and protection across a multitude of industries. Its ability to filter out tiny particles, coupled with its strength and durability, makes it an invaluable tool for ensuring the purity and safety of products and environments. Whether used in industrial settings or incorporated into architectural designs, very fine screen mesh provides a combination of practicality and aesthetic appeal that is hard to match. As technology advances and the demand for finer filtration grows, the role of very fine screen mesh is likely to become even more prominent, solidifying its status as the best choice for those seeking the highest level of performance.