what is polyurethane board,polyurethane screen,pu screen panel

Understanding polyurethane Board: Composition, Uses, and Benefits Polyurethane, a versatile polymer, has found its way into various industries due to its exceptional…

Understanding polyurethane Board: Composition, Uses, and Benefits

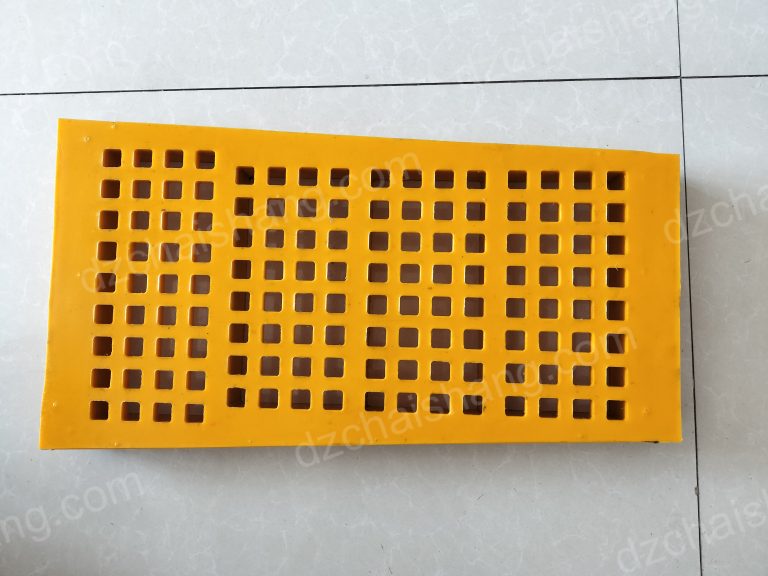

Polyurethane, a versatile polymer, has found its way into various industries due to its exceptional properties. Among its many applications, polyurethane board, polyurethane screen, and pu screen panel stand out for their unique benefits and uses. Understanding the composition, applications, and advantages of these polyurethane-based products can provide insights into why they are increasingly preferred in numerous fields. Polyurethane board is a type of insulation material that is manufactured by combining polyol and isocyanate, two compounds that react to form a rigid, dense foam. This foam is known for its excellent insulation properties, making it an ideal choice for construction and refrigeration industries. The board’s high thermal resistance helps in maintaining temperature control, leading to energy efficiency and cost savings. Moreover, its lightweight nature, coupled with its structural strength, makes it easy to handle and install, further enhancing its appeal in the construction sector. Transitioning from the polyurethane board to the realm of polyurethane screens and PU screen panels, one can observe a shift in application but not in the innovative use of polyurethane. Polyurethane screens are widely used in the mining and aggregate industries for screening operations. These screens are made by pouring polyurethane into molds to create panels that fit various types of screening equipment. The inherent flexibility and durability of polyurethane make these screens highly resistant to abrasion and wear, significantly extending their lifespan compared to traditional wire mesh screens. This durability is crucial in harsh screening environments where materials being processed can quickly degrade less robust screening solutions. pu screen panels further exemplify the adaptability of polyurethane in screening applications. These panels are designed to fit into a wide range of screening systems, offering customization options that can meet specific operational requirements. The panels can be manufactured with different levels of hardness, aperture sizes, and panel sizes, making them suitable for a variety of screening tasks, from fine to coarse materials. The versatility of PU screen panels allows for their use in wet and dry screening processes, showcasing the material’s ability to perform under diverse conditions. The benefits of using polyurethane in these applications are manifold. Firstly, the durability and wear resistance of polyurethane reduce the need for frequent replacements, leading to cost savings and increased operational efficiency. Secondly, the material’s flexibility allows for improved screening performance, as it can better absorb impact and reduce blinding and pegging during the screening process. This results in a more efficient separation of materials and higher product quality. Lastly, polyurethane’s resistance to chemicals, oil, and water makes it suitable for use in a wide range of environments, further broadening its applicability. In conclusion, polyurethane board, polyurethane screen, and PU screen panel represent the innovative use of polyurethane in various industries. From construction and insulation to mining and aggregate processing, the unique properties of polyurethane offer significant advantages over traditional materials. Its durability, flexibility, and resistance to harsh conditions make it an ideal choice for applications requiring high performance and longevity. As industries continue to seek efficient and cost-effective solutions, the role of polyurethane in meeting these demands is likely to grow, underscoring its importance in modern manufacturing and industrial processes.Exploring Polyurethane Screens: Applications in Industrial Filtration and Separation

Exploring Polyurethane Screens: Applications in Industrial Filtration and Separation In the realm of industrial filtration and separation, materials and technologies play pivotal roles in ensuring efficiency, durability, and effectiveness. Among these, polyurethane has emerged as a standout material, thanks to its remarkable properties. This article delves into the world of polyurethane screens, focusing on polyurethane board, polyurethane screen, and PU screen panel, to shed light on their significance and applications in various industries. Polyurethane, a versatile polymer, is renowned for its exceptional resistance to abrasion, wear, and tear, making it an ideal choice for harsh industrial environments. Its flexibility allows for the creation of products in various shapes and sizes, catering to a wide range of applications. Among these products, polyurethane screens stand out for their critical role in filtration and separation processes. Starting with the polyurethane board, it serves as the foundational element in the construction of polyurethane screens. The board is manufactured through a process that ensures it possesses the inherent qualities of polyurethane, such as flexibility, durability, and resistance to various chemicals and environmental factors. This makes it an excellent base material for screens used in demanding industrial applications, where longevity and reliability are paramount.

Transitioning from the polyurethane board, the polyurethane screen represents a significant advancement in screening technology. These screens are designed to facilitate efficient separation and filtration of materials in industries such as mining, quarrying, and recycling. The unique structure of polyurethane screens, combined with their material properties, allows for improved screening performance. They effectively reduce blinding and pegging, common challenges in screening processes, thereby enhancing productivity and operational efficiency. Moreover, the adaptability of polyurethane screens to various screening environments is noteworthy. They can be customized to fit different screening machines and applications, making them a versatile solution for many industrial needs. This adaptability extends to the PU screen panel, a specific type of polyurethane screen designed for modular applications. The PU screen panel embodies the essence of polyurethane’s advantages in a modular format. These panels are easily replaceable and can be configured to meet the specific requirements of a screening process. Their modular nature allows for quick and easy maintenance, reducing downtime and increasing the overall efficiency of the operation. Furthermore, PU screen panels are available in different designs and apertures, enabling precise separation and filtration according to the material characteristics and process requirements. In conclusion, the exploration of polyurethane screens, from polyurethane board to PU screen panel, reveals their critical role in industrial filtration and separation. Their exceptional material properties, combined with innovative design and adaptability, make them an indispensable tool in enhancing the efficiency and effectiveness of industrial processes. As industries continue to evolve and demand more from their filtration and separation solutions, polyurethane screens stand ready to meet these challenges, offering a durable, efficient, and versatile option for various applications.