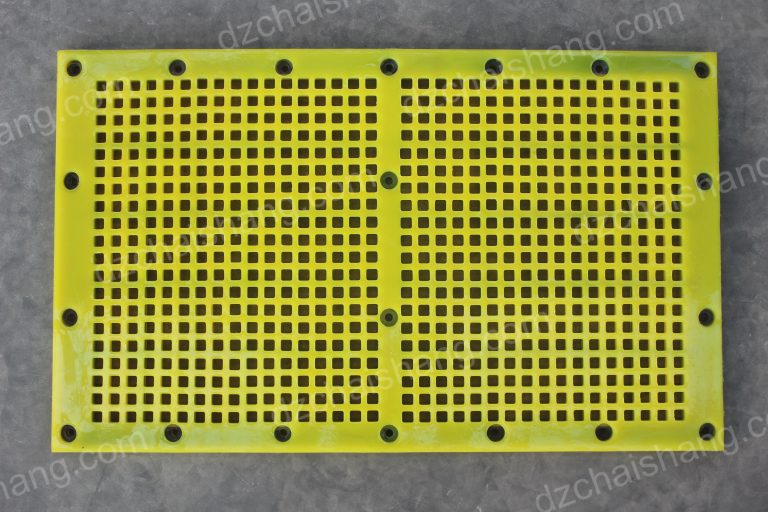

secondary conveyor cleaner,mining conveyor blade,polyurethane conveyor blade

The Benefits of Using Secondary Conveyor Cleaners in mining Operations Secondary conveyor cleaners are an essential component of any mining operation. They…

The Benefits of Using Secondary Conveyor Cleaners in mining Operations

Secondary conveyor cleaners are an essential component of any mining operation. They provide a safe and efficient way to remove debris from conveyor belts, helping to reduce downtime and improve productivity. In addition to their practical benefits, secondary conveyor cleaners also offer a number of advantages over traditional methods of cleaning. First, secondary conveyor cleaners are much more efficient than manual cleaning methods. By using a secondary conveyor cleaner, operators can quickly and easily remove debris from conveyor belts without having to manually scrape or brush the material away. This can significantly reduce the amount of time and labor required to keep conveyor belts clean. Second, secondary conveyor cleaners are much safer than manual cleaning methods. Manual cleaning methods can be dangerous, as operators must be in close proximity to the conveyor belt while cleaning. With a secondary conveyor cleaner, operators can remain at a safe distance while the machine does the work. This reduces the risk of injury and makes the job much safer for everyone involved.

Finally, secondary conveyor cleaners are much more cost-effective than manual cleaning methods. Manual cleaning methods require a significant amount of labor and can be expensive. By using a secondary conveyor cleaner, operators can reduce labor costs and save money in the long run.

Second, secondary conveyor cleaners are much safer than manual cleaning methods. Manual cleaning methods can be dangerous, as operators must be in close proximity to the conveyor belt while cleaning. With a secondary conveyor cleaner, operators can remain at a safe distance while the machine does the work. This reduces the risk of injury and makes the job much safer for everyone involved.

Finally, secondary conveyor cleaners are much more cost-effective than manual cleaning methods. Manual cleaning methods require a significant amount of labor and can be expensive. By using a secondary conveyor cleaner, operators can reduce labor costs and save money in the long run.