Ffatri vibrator fflip fflop PU panel mwynglawdd, Ffatri rhwyll tensiwn polywrethan

Archwilio Manteision a Chymwysiadau Paneli PU Flip Flip Vibrator Ffatri a Rhwyll Tensiwn Polywrethan mewn Prosesu Mwynau Mae paneli PU fflip fflop…

Archwilio Manteision a Chymwysiadau Paneli PU Flip Flip Vibrator Ffatri a Rhwyll Tensiwn Polywrethan mewn Prosesu Mwynau

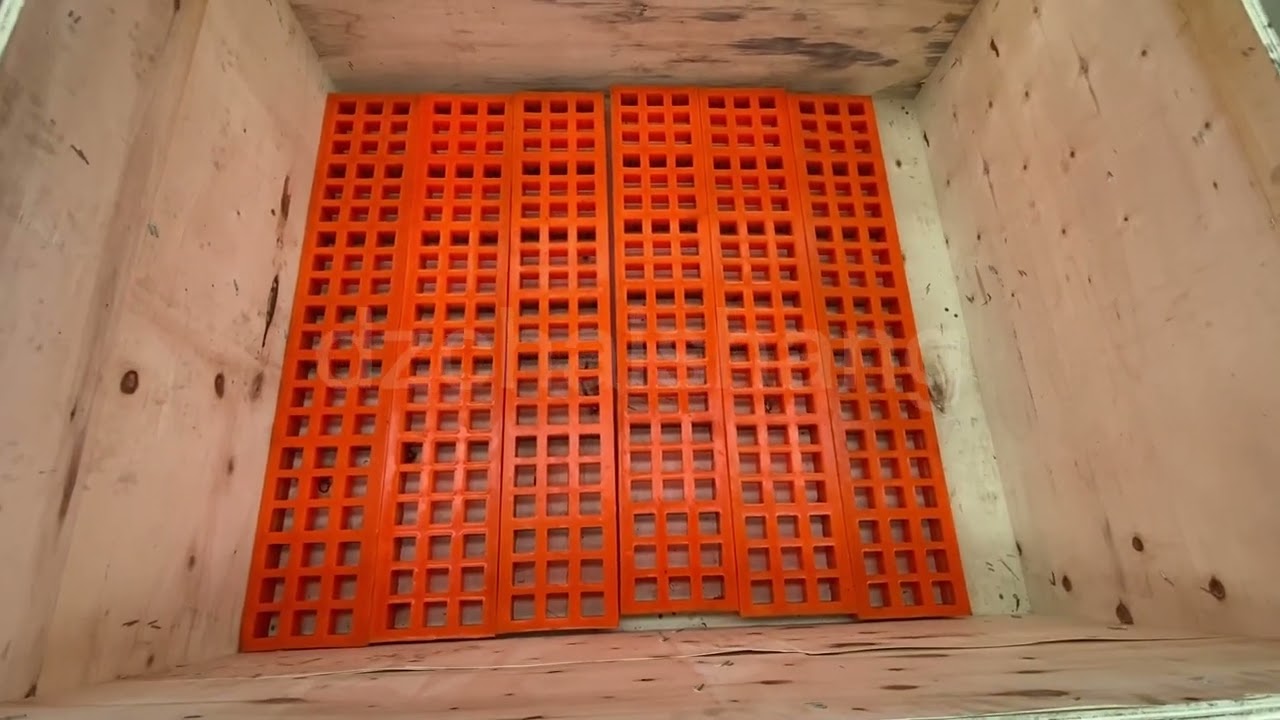

Mae paneli PU fflip fflop vibrator vibrator a rhwyll tensiwn polywrethan yn ddau ddatrysiad arloesol sydd wedi chwyldroi’r diwydiant prosesu mwynau. Mae’r deunyddiau datblygedig hyn yn cynnig ystod o fuddion sy’n gwella effeithlonrwydd ac effeithiolrwydd gweithrediadau prosesu mwynau, gan eu gwneud yn offer anhepgor ar gyfer ffatrïoedd modern.

amgylcheddau prosesu mwynau. Wedi’u gwneud o polywrethan o ansawdd uchel, mae’r paneli hyn yn gallu gwrthsefyll traul, sgraffinio a chorydiad yn fawr. Mae’r gwydnwch hwn yn sicrhau y gall y paneli drin llwythi trwm a gweithrediad parhaus heb ddiraddio, gan arwain at oes hirach a llai o gostau cynnal a chadw. Yn ogystal, mae hyblygrwydd polywrethan yn caniatáu i’r paneli hyn amsugno effaith a dirgryniadau, sy’n helpu i amddiffyn y peiriannau a lleihau lefelau sŵn yn y ffatri.

Un o fanteision allweddol paneli PU fflip-fflop vibrator ffatri yw eu gallu i wella effeithlonrwydd o brosesau sgrinio. Mae dyluniad unigryw’r paneli hyn yn caniatáu iddynt fflipio a fflipio yn ystod y llawdriniaeth, sy’n helpu i atal clocsio a dallu’r sgrin. Mae hyn yn sicrhau bod y gronynnau mwynol yn cael eu gwahanu a’u dosbarthu’n effeithiol, gan arwain at gynhyrchion o ansawdd uwch a chynhyrchiant cynyddol. Ar ben hynny, gellir addasu’r paneli i fodloni gofynion penodol, megis agorfa o wahanol feintiau a siapiau, sy’n caniatáu rheolaeth fanwl gywir dros y broses sgrinio.

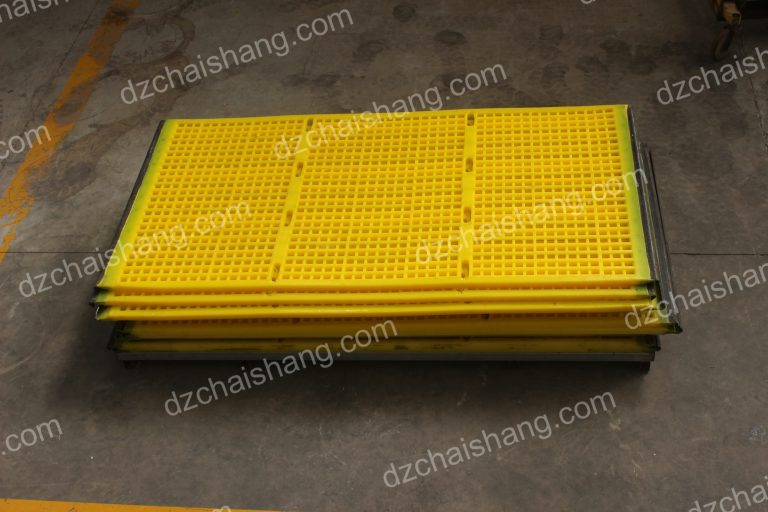

Mae rhwyll tensiwn polywrethan, ar y llaw arall, yn arf gwerthfawr arall mewn prosesu mwynau. Mae’r math hwn o rwyll wedi’i wneud o polywrethan tynnol uchel, sy’n darparu cryfder a gwydnwch rhagorol. Mae dyluniad tensiwn y rhwyll yn sicrhau ei fod yn aros yn dynn yn ystod y llawdriniaeth, sy’n helpu i wella cywirdeb ac effeithlonrwydd y broses sgrinio. Mae’r rhwyll hefyd yn gallu gwrthsefyll traul yn fawr, sy’n lleihau’r angen am ailosod yn aml ac yn lleihau costau cynnal a chadw.

Mae cymwysiadau rhwyll tensiwn polywrethan yn amrywiol ac yn ymestyn y tu hwnt i brosesu mwynau. Defnyddir y rhwyll hon yn gyffredin hefyd mewn diwydiannau eraill, megis amaethyddiaeth, adeiladu ac ailgylchu, lle mae prosesau sgrinio a gwahanu yn hollbwysig. Yn y cymwysiadau hyn, mae’r rhwyll yn helpu i gael gwared ar ddeunyddiau a halogion diangen, gan arwain at gynhyrchion glanach ac o ansawdd uwch.

Ar ben hynny, mae rhwyll tensiwn polywrethan ar gael mewn amrywiaeth o feintiau a siapiau agorfa, sy’n caniatáu addasu i ddiwallu anghenion penodol. Mae’r amlochredd hwn yn ei gwneud yn ddewis delfrydol ar gyfer ystod eang o gymwysiadau sgrinio, lle mae angen gwahanu gwahanol ddeunyddiau a meintiau gronynnau.

I gloi, mae paneli PU fflip fflop vibrator ffatri a rhwyll tensiwn polywrethan yn gydrannau hanfodol yn y diwydiant prosesu mwynau. Mae’r deunyddiau hyn yn cynnig ystod o fanteision, gan gynnwys gwydnwch, effeithlonrwydd ac amlochredd, sy’n eu gwneud yn offer gwerthfawr ar gyfer gwella ansawdd a chynhyrchiant gweithrediadau prosesu mwynau. P’un a yw mewn mwyngloddio, amaethyddiaeth neu ailgylchu, mae’r deunyddiau datblygedig hyn yn darparu atebion effeithiol ar gyfer prosesau sgrinio a gwahanu, gan arwain at ganlyniadau gwell ac enillion uwch ar fuddsoddiad. Wrth i dechnoleg barhau i ddatblygu, mae’n debygol y bydd y deunyddiau hyn yn parhau i chwarae rhan hanfodol wrth lunio dyfodol y diwydiant.