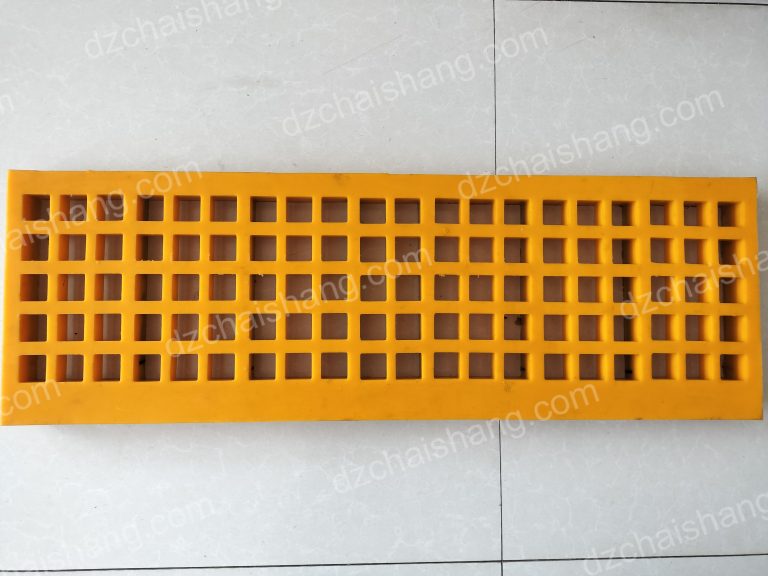

China tensioned mesh sieve,sieve plate,polyurethane screen panel

Exploring the Role of China’s tensioned mesh Sieve in Industrial Applications China has emerged as a global leader in the manufacturing sector,…

Exploring the Role of China’s tensioned mesh Sieve in Industrial Applications

China has emerged as a global leader in the manufacturing sector, with its tensioned mesh sieve, sieve plate, and polyurethane screen panel products playing a pivotal role in various industrial applications. These products, known for their durability, efficiency, and versatility, have become indispensable tools in industries ranging from mining to agriculture, and from construction to food processing. The tensioned mesh sieve, a product that has gained significant traction in recent years, is a prime example of China’s innovative approach to industrial manufacturing. This product is designed with a high-tension wire mesh that is capable of filtering and separating materials of different sizes and densities. The tensioned mesh sieve is particularly useful in the mining industry, where it is used to separate valuable minerals from unwanted rock and soil. Its high-tensile strength and resistance to wear and tear make it an ideal tool for this rigorous and demanding application. In addition to the tensioned mesh sieve, China’s sieve plate is another product that has made a significant impact on the industrial sector. The sieve plate is a perforated metal sheet used to separate, filter, and classify materials. It is commonly used in industries such as coal, metallurgy, and chemical engineering. The sieve plate’s robust design and high filtration efficiency make it an essential tool in these industries. Its ability to withstand high temperatures and corrosive materials further enhances its utility in these harsh industrial environments. China’s polyurethane screen panel is yet another product that has revolutionized industrial processes. This product is made from high-quality polyurethane, a material known for its durability and resistance to wear, tear, and corrosion. The polyurethane screen panel is used in various applications, including dewatering, desliming, and heavy medium separation. Its flexibility allows it to be used in different types of machinery, making it a versatile tool in the industrial sector.Innovation in Mining: The Impact of Polyurethane Screen Panels from China

Innovation in mining has always been a critical factor in the industry’s growth and development. One such innovation that has significantly impacted the mining sector is the introduction of polyurethane screen panels from China. These panels, also known as tensioned mesh sieves or sieve plates, have revolutionized the way mining operations are conducted, offering a plethora of benefits that have significantly improved efficiency and productivity. Polyurethane screen panels are a product of advanced technology and innovative design. They are made from high-quality polyurethane, a material known for its durability and resilience. This makes them highly resistant to wear and tear, even under the most challenging mining conditions. Consequently, these panels have a longer lifespan compared to traditional metal screens, reducing the need for frequent replacements and thereby cutting down operational costs. Moreover, the unique design of these panels, featuring a tensioned mesh sieve, allows for more precise and efficient sieving. The mesh design ensures that the material is evenly distributed across the screen, reducing the likelihood of blockages and improving the overall efficiency of the sieving process. This not only speeds up the mining operation but also enhances the quality of the output. In addition, polyurethane screen panels are lightweight and easy to install. This ease of installation reduces downtime during screen changes, further enhancing operational efficiency. Furthermore, their lightweight nature means they require less energy to operate, contributing to a reduction in energy costs and promoting environmentally friendly mining practices.

China, as the leading manufacturer of these innovative screen panels, has played a pivotal role in their widespread adoption. Chinese manufacturers have leveraged their technological prowess and manufacturing capabilities to produce high-quality, reliable, and cost-effective polyurethane screen panels. These panels are now used in mining operations worldwide, testament to their effectiveness and the trust that the global mining industry has placed in Chinese manufacturing. However, the impact of these panels extends beyond just operational efficiency and cost savings. By reducing the need for frequent screen replacements, they also contribute to worker safety. Mining is a high-risk industry, and any measure that reduces the potential for accidents is a welcome development. The durability of polyurethane screen panels means fewer screen changes are required, reducing the risk of accidents during this potentially hazardous operation. Furthermore, the use of polyurethane, a recyclable material, in the manufacture of these panels aligns with the growing emphasis on sustainable mining practices. By choosing polyurethane screen panels, mining companies are not only improving their operational efficiency but also making a positive contribution to environmental sustainability. In conclusion, the introduction of polyurethane screen panels from China has had a profound impact on the mining industry. These panels, with their unique tensioned mesh sieve design, offer numerous benefits, including improved operational efficiency, cost savings, enhanced worker safety, and environmental sustainability. As the mining industry continues to evolve and seek new ways to improve its operations, it is clear that innovations like these will continue to play a crucial role.