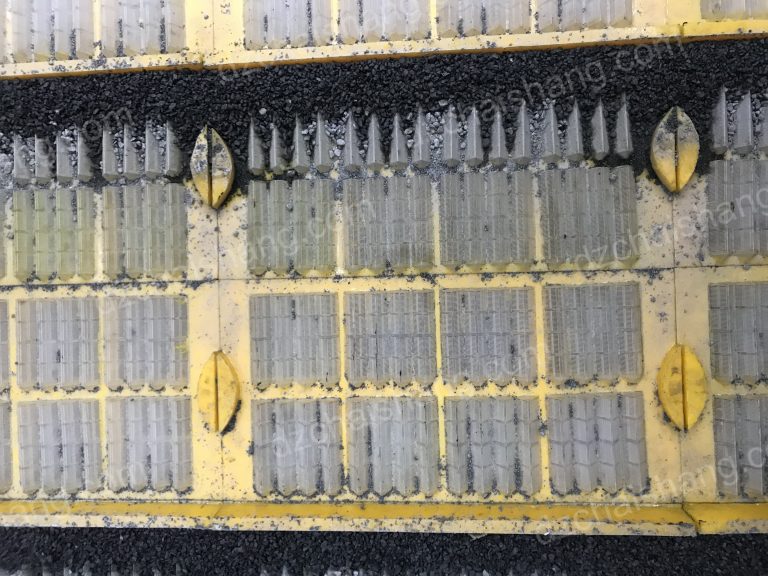

Factory high frequency Urethane panel,factory vibrator high frequency Polyurethane screen

How Factory high frequency urethane Panels and Vibrator High Frequency polyurethane screens Improve Efficiency in Manufacturing Factory high frequency urethane panels and…

How Factory high frequency urethane Panels and Vibrator High Frequency polyurethane screens Improve Efficiency in Manufacturing

Factory high frequency urethane panels and vibrator high frequency polyurethane screens are becoming increasingly popular in manufacturing operations due to their ability to improve efficiency. These panels and screens are designed to reduce noise and vibration, which can be a major source of disruption in a manufacturing environment.

The panels and screens are made from a special type of polyurethane that is designed to absorb sound and vibration. This material is highly durable and can withstand the rigors of a manufacturing environment. The panels and screens are also designed to be lightweight, making them easy to install and maintain.

The panels and screens are also designed to be highly efficient. They are able to absorb sound and vibration quickly, reducing the amount of time it takes for the sound and vibration to dissipate. This reduces the amount of time it takes for the manufacturing process to complete, resulting in increased efficiency.

The panels and screens also help to reduce the amount of energy used in the manufacturing process. By absorbing sound and vibration, they reduce the amount of energy needed to power the machinery. This can result in significant cost savings for the manufacturer.

Finally, the panels and screens are designed to be highly durable. They are able to withstand the wear and tear of a manufacturing environment, ensuring that they will last for many years. This helps to reduce the amount of money that needs to be spent on replacement parts and repairs.

Overall, factory high frequency urethane panels and vibrator high frequency polyurethane screens are an excellent way to improve efficiency in a manufacturing environment. They are designed to reduce noise and vibration, resulting in increased efficiency and cost savings. They are also highly durable, ensuring that they will last for many years.