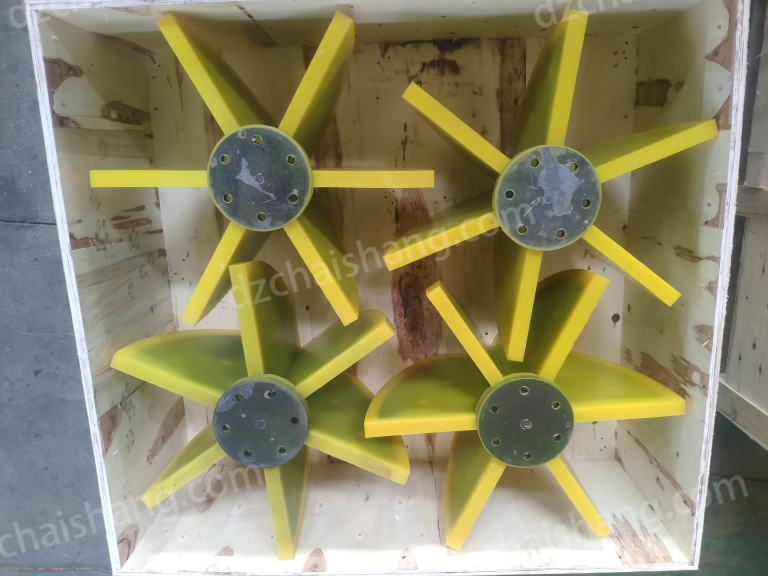

High Quality shaker circular vibrating Polyurethane Media Aggregate

Benefits of Using High Quality Shaker Circular Vibrating polyurethane Media Aggregate High quality shaker circular vibrating polyurethane media aggregate is a versatile…

Benefits of Using High Quality Shaker Circular Vibrating polyurethane Media Aggregate

High quality shaker circular vibrating polyurethane media aggregate is a versatile and efficient material that offers a wide range of benefits for various industries. From mining and construction to recycling and agriculture, this innovative product has become a popular choice for businesses looking to improve their operations and increase productivity. One of the key benefits of using high quality shaker circular vibrating polyurethane media aggregate is its durability. Made from high-quality polyurethane material, this media aggregate is designed to withstand the rigors of heavy-duty applications. Whether it’s being used in a vibrating screen, a shaker table, or a trommel, this material can handle the demands of continuous use without wearing out or breaking down. In addition to its durability, high quality shaker circular vibrating polyurethane media aggregate is also known for its efficiency. The circular vibrating motion of this material helps to separate and classify particles quickly and effectively, resulting in a more efficient screening process. This can lead to increased throughput, reduced downtime, and improved overall productivity for businesses that rely on this material for their operations. Another benefit of using high quality shaker circular vibrating polyurethane media aggregate is its versatility. This material can be customized to meet the specific needs of different applications, making it suitable for a wide range of industries and processes. Whether it’s being used to separate aggregates in a mining operation or to classify materials in a recycling facility, this material can be tailored to deliver optimal performance in any setting.

Furthermore, high quality shaker circular vibrating polyurethane media aggregate is also known for its cost-effectiveness. While initial investment costs may be higher compared to other screening materials, the long-term benefits of using this material far outweigh the upfront expenses. With its durability, efficiency, and versatility, businesses can expect to see a significant return on investment over time.

In addition to these practical benefits, high quality shaker circular vibrating polyurethane media aggregate also offers environmental advantages. This material is made from recyclable polyurethane, making it a sustainable choice for businesses looking to reduce their environmental impact. By using this material in their operations, businesses can minimize waste and contribute to a more sustainable future.

Overall, high quality shaker circular vibrating polyurethane media aggregate offers a wide range of benefits for businesses across various industries. From its durability and efficiency to its versatility and cost-effectiveness, this material is a valuable asset for any business looking to improve their screening processes and increase productivity. With its environmental advantages, this material is also a sustainable choice for businesses looking to reduce their carbon footprint and contribute to a greener future.

Another benefit of using high quality shaker circular vibrating polyurethane media aggregate is its versatility. This material can be customized to meet the specific needs of different applications, making it suitable for a wide range of industries and processes. Whether it’s being used to separate aggregates in a mining operation or to classify materials in a recycling facility, this material can be tailored to deliver optimal performance in any setting.

Furthermore, high quality shaker circular vibrating polyurethane media aggregate is also known for its cost-effectiveness. While initial investment costs may be higher compared to other screening materials, the long-term benefits of using this material far outweigh the upfront expenses. With its durability, efficiency, and versatility, businesses can expect to see a significant return on investment over time.

In addition to these practical benefits, high quality shaker circular vibrating polyurethane media aggregate also offers environmental advantages. This material is made from recyclable polyurethane, making it a sustainable choice for businesses looking to reduce their environmental impact. By using this material in their operations, businesses can minimize waste and contribute to a more sustainable future.

Overall, high quality shaker circular vibrating polyurethane media aggregate offers a wide range of benefits for businesses across various industries. From its durability and efficiency to its versatility and cost-effectiveness, this material is a valuable asset for any business looking to improve their screening processes and increase productivity. With its environmental advantages, this material is also a sustainable choice for businesses looking to reduce their carbon footprint and contribute to a greener future.